Designed for Operators

Built for Owners

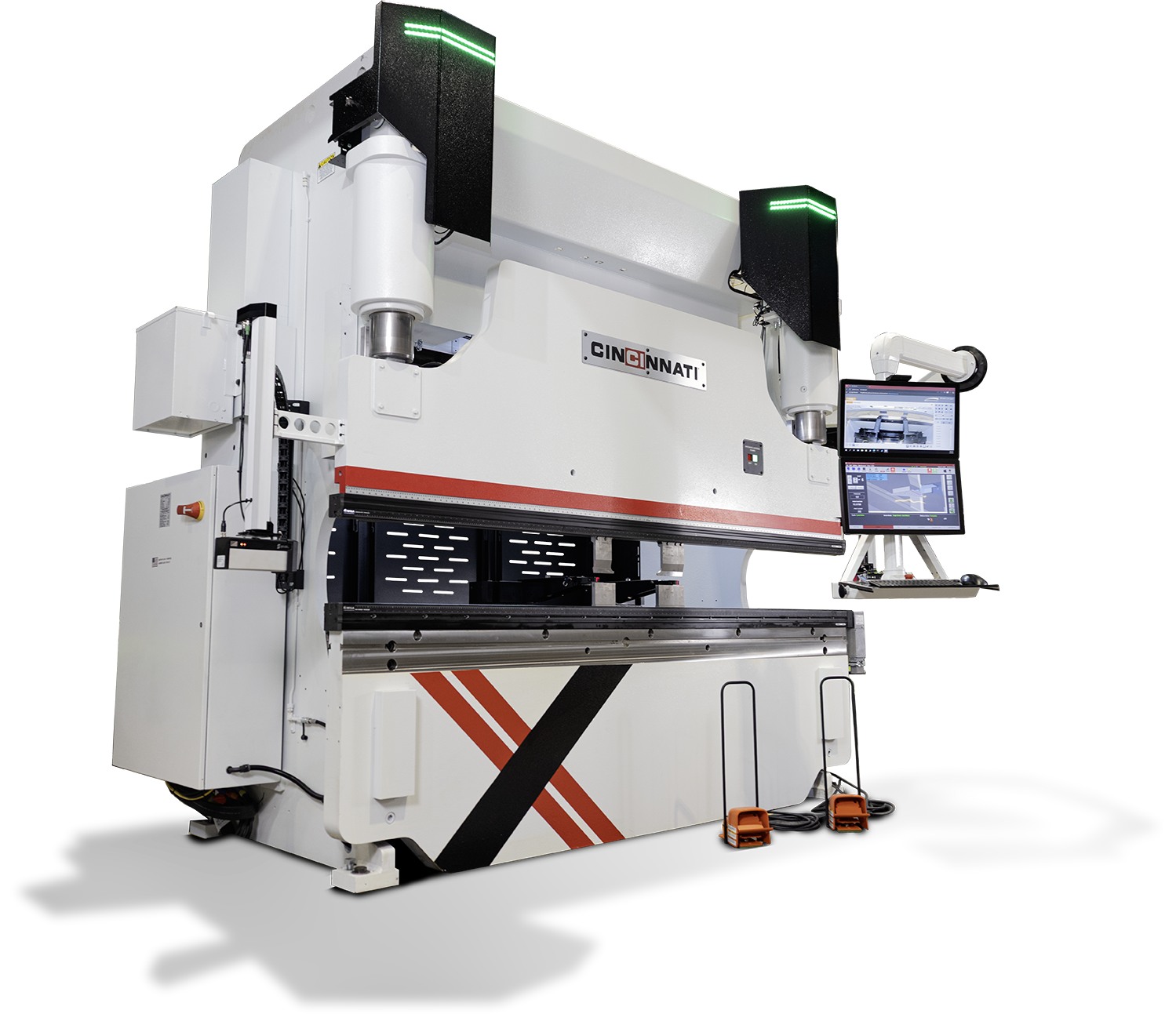

Get ready to witness the future of precision metal fabrication with the groundbreaking XFORM Press Brake. This cutting-edge machine not only offers industry-leading speeds, but also features CINCINNATI's renowned construction, an ergonomic design, and a plethora of innovative advancements.

Where Modern Meets POWER

The XFORM is the next generation of CINCINNATI press brakes. With it's all-new hydraulic drive system, built using CI’s proven and reliable premium construction ensures reliable and long life. Now with faster ram speeds, a quieter drive systems, larger control screen, larger standard stroke and throat, and a standard 5-axis backgage the XFORM brings even more productivity to your fabrication operations.

Hydraulic Model

The XFORM offers faster ram speed with a quieter drive system.

Hybrid Model

The XFORMe version offers faster ram speeds and a quieter drive system with reduced operating costs.

Custom Model

The XFORMc offers a fast hydraulic system in additional lengths and a customized experience based on your unique needs.

The XFORM Series Press Brake Just Got an Upgrade

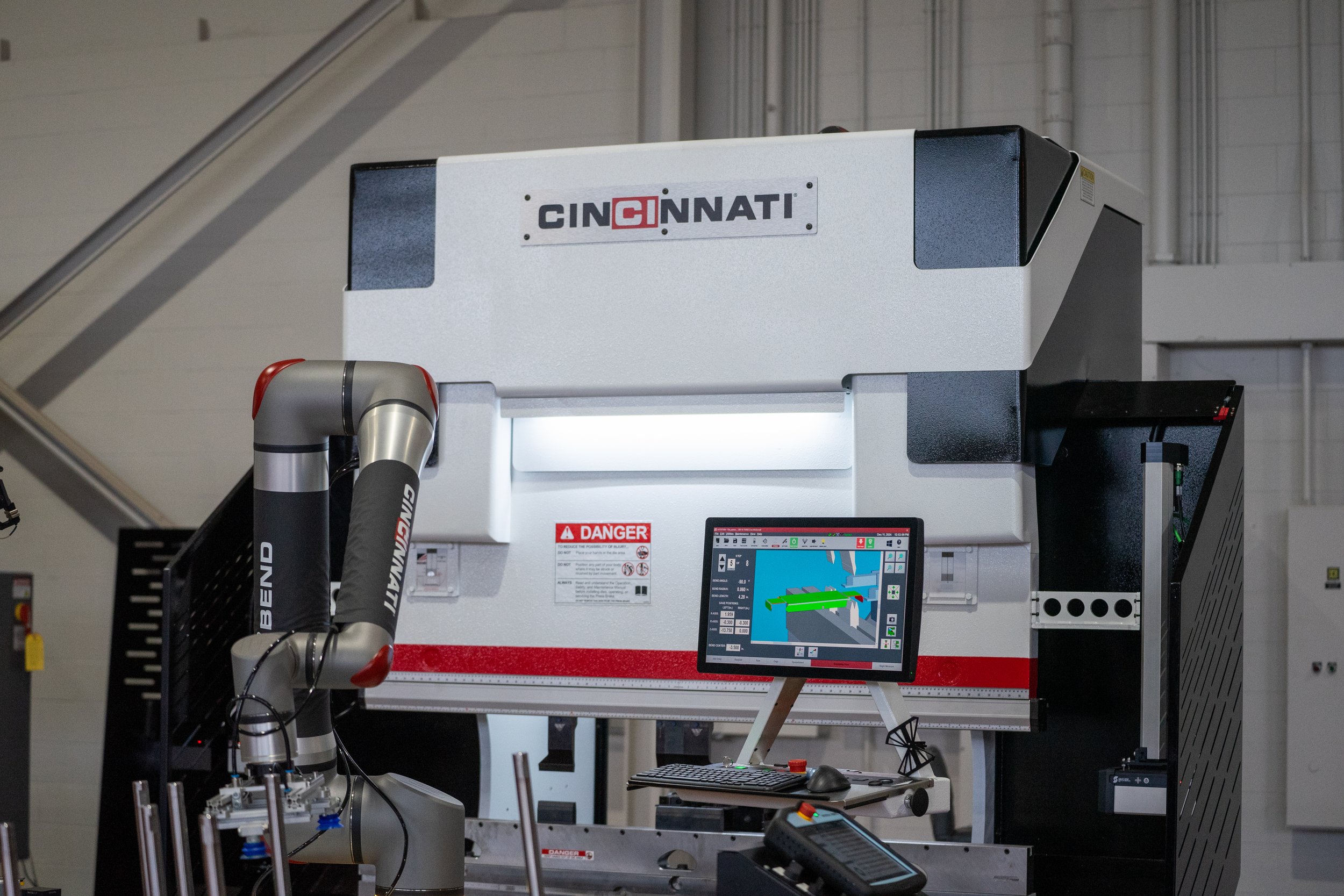

We're excited to introduce the redesigned cylinder covers for the XFORM Series press brake. Now featuring a tool-free, swing-out design for easy access and indicator lights that sync with CIberDash, you can streamline your service process and get instant updates on machine status.

The XFORM is equipped with these key features

-

NEW! Indicator Lights

Instantly view the status of the machine anywhere in the shop with the new and modern indicator lights available on the XFORM and XFORMe models.

-

Dynamic Thickness Compensation (DTC)

DTC is now standard on the XFORM and XFORMe models, providing you with the ability to automatically compensate for material thickness variations allowing you to get more accurate bends. Learn More about DTC

-

Clevis Mounted Cylinders

These cylinders are mounted with clevis brackets, providing a secure attachment point. They enable precise control and powerful force application, ensuring efficient bending and forming of metal sheets.

-

Industry-Leading Speeds

Enjoy an impressive 500+ IPM ram approach speeds allowing you to get more done.

-

Extended Stroke & Throat

Bend a wider variety of parts with larger standard stroke and throat options.

-

Touchscreen Controls

Control every aspect of your machine with the high resolution, 24” touch screen monitors with 3D graphics for fast setup and part handling, Bend Simulation software with automatic bend sequencing and interference checking and advanced angle correction.

-

Interlocked Construction

Features an advanced CINCINNATI Strong interlocked construction, setting a new standard in safety and performance. This design ensures maximum stability and precision during metal fabrication operations. Experience peace of mind while achieving impeccable results.

-

5-Axis Backgage

With the ability to control not only the depth and position but also the angle and height of the backgage, the XFORM’s 5-Axis Backgage empowers operators to achieve complex and accurate bends effortlessly.

Monitor your laser’s health, anytime from any device with

Add these premium features to your XFORM

Technical Specifications of the XFORM and XFORMe

Due to a continuous product development program, engineering data and dimensions are subject to change without notice. Certified foundation plans will be furnished for each installation.

| Model | Overall Die Surface (ft.) | Closed Height (in.) | Stroke Length (in.) | Open Height (in.) | Throat (in.) | Approach Speed (ipm) | Forming Speed (ipm) | Return Speed (ipm) |

|---|---|---|---|---|---|---|---|---|

| 90XF6 | 8 | 7 | 14 | 21 | 18 | 650 | 75 | 565 |

| 90XF8 | 10 | 7 | 14 | 21 | 18 | 650 | 75 | 565 |

| 135XF8 | 10 | 7 | 14 | 21 | 18 | 650 | 55 | 540 |

| 135XF10 | 12 | 7 | 14 | 21 | 18 | 650 | 55 | 540 |

| 175XF8 | 10 | 7 | 16 | 23 | 18 | 550 | 45 | 485 |

| 175XF10 | 12 | 7 | 16 | 23 | 18 | 550 | 45 | 485 |

| 230XF10 | 12 | 7 | 16 | 23 | 18 | 550 | 35 | 430 |

| 230XF12 | 14 | 7 | 16 | 23 | 18 | 550 | 35 | 430 |

| 350XF10 | 12 | 8 | 16 | 24 | 18 | 300 | 30 | 330 |

| 350XF12 | 14 | 8 | 16 | 24 | 18 | 300 | 30 | 330 |

The XFORMe, the energy-efficient hybrid drive version XFORM, shares the same premium construction features as the all-hydraulic XFORM. Benefits of the XFORMe are an even quieter drive system, reduced operating costs, and simplified maintenance. The XFORMe's efficient dual servo-motor bidirectional pump drive system runs only during the working portion of the stroke (tonnage on demand) reducing energy consumption when the ram is idle. The XFORMe simplifies maintenance with a low-capacity hydraulic system that uses a fire-resistant and biodegradable hydraulic fluid in place of traditional hydraulic oil. This provides longer life, safer handling and non-hazardous waste disposal.

| Model | Overall Die Surface (ft.) | Closed Height (in.) | Stroke Length (in.) | Open Height (in.) | Throat (in.) | Approach Speed (ipm) | Forming Speed (ipm) | Return Speed (ipm) |

|---|---|---|---|---|---|---|---|---|

| 90XFe6 | 8 | 7 | 14 | 21 | 18 | 550 | 70 | 550 |

| 90XFe8 | 10 | 7 | 14 | 21 | 18 | 550 | 70 | 550 |

| 135XFe8 | 10 | 7 | 14 | 21 | 18 | 550 | 70 | 550 |

| 135XFe10 | 12 | 7 | 14 | 21 | 18 | 550 | 70 | 550 |

| 175XeF8 | 10 | 7 | 16 | 23 | 18 | 550 | 70 | 550 |

| 175XFe10 | 12 | 7 | 16 | 23 | 18 | 550 | 70 | 550 |

| 230XFe10 | 12 | 7 | 16 | 23 | 18 | 550 | 55 | 550 |

| 230XFe12 | 14 | 7 | 16 | 23 | 18 | 550 | 55 | 550 |

| 350XFe10 | 12 | 8 | 16 | 24 | 18 | 350 | 35 | 350 |

| 350XFe12 | 14 | 8 | 16 | 24 | 18 | 350 | 35 | 350 |