Walk the aisles of Fabtech, IMTS, EMO, PMTS, and any number of regional metal processing shows, and you will see an endless parade of machine tool types, sizes, and brands. All are basically quality machines from reputable companies, so why should you choose one over the other? Does it really matter?

The short answer is, if you’re simply looking for a machine that cuts or bends metal, then price is probably the deciding factor. But for those who want more than just a machine, there can be a world of difference.

The Smart Choice for Metal Fabricators

A Legacy of Manufacturing

With more than a century of experience, Cincinnati Incorporated has been designing and building machines since 1898. But CI’s legacy is about more than longevity, it’s a testament to its enduring commitment to customers and continuous improvement. Behind the name is a dedicated workforce (including many veterans), rigorous quality standards, and precise control over supply chains and production schedules.

The Harrison, Ohio company has distinguished itself through high-quality, innovative fabrication equipment, backed by exceptional support and a deep understanding of its customers' needs. Tightly integrated manufacturing operations enable fast lead times, consistent quality, and responsive service - advantages that are increasingly vital in today’s competitive manufacturing environment.

With a focus on reliability, innovation, and long-term support, CI has earned its place as a trusted partner across industries.

More than Machines

Listen to stories from CI staff about their experiences and career journeys at Cincinnati Incorporated

A Strategic Manufacturing Partner

CI positions itself as a partner to its customers. That means understanding the unique production challenges of each fabricator and engineering solutions that go beyond off-the-shelf equipment. Whether it’s customizing a press brake to fit a shop’s workflow or providing advanced automation integration, CI works closely with customers to enhance productivity and profitability.

Fab shops, job shops, metal service centers, and OEMs across the country have scaled their output, improved throughput, and tackled complex jobs thanks to this collaborative approach. When an equipment provider like CI is invested in your success, the relationship becomes a strategic advantage.

Let’s talk more about your goals

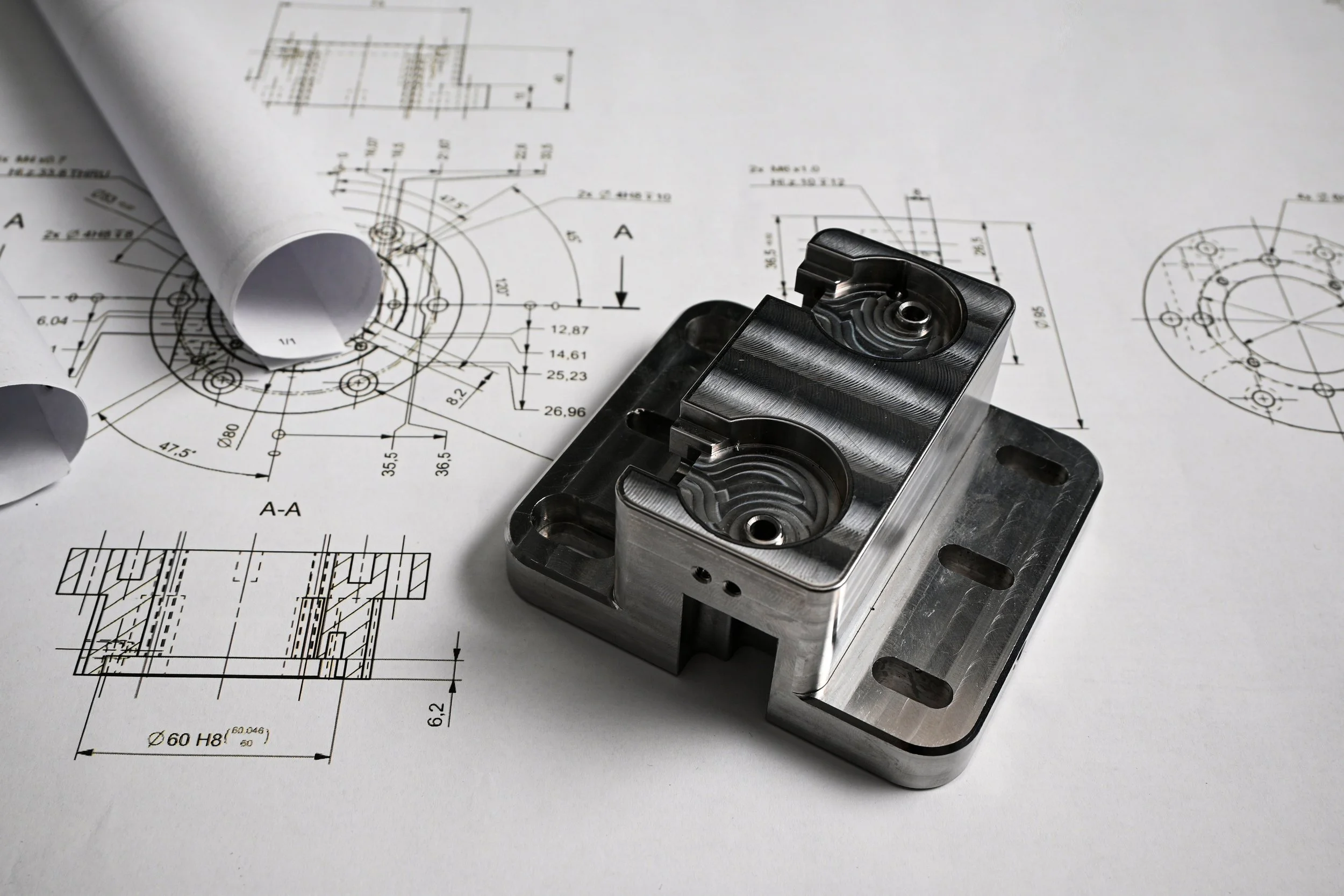

Products and Services with Quality and Innovation at the Core

At CI, quality is backed by decades of engineering excellence and a culture of continuous innovation. The company’s product lineup defines the standard for innovation, longevity, and precision in metal fabrication. From robust, versatile press brakes to industry-iconic shears and high-performance fiber lasers, CI machines are engineered for long-term durability, outstanding accuracy, and consistent performance.

-

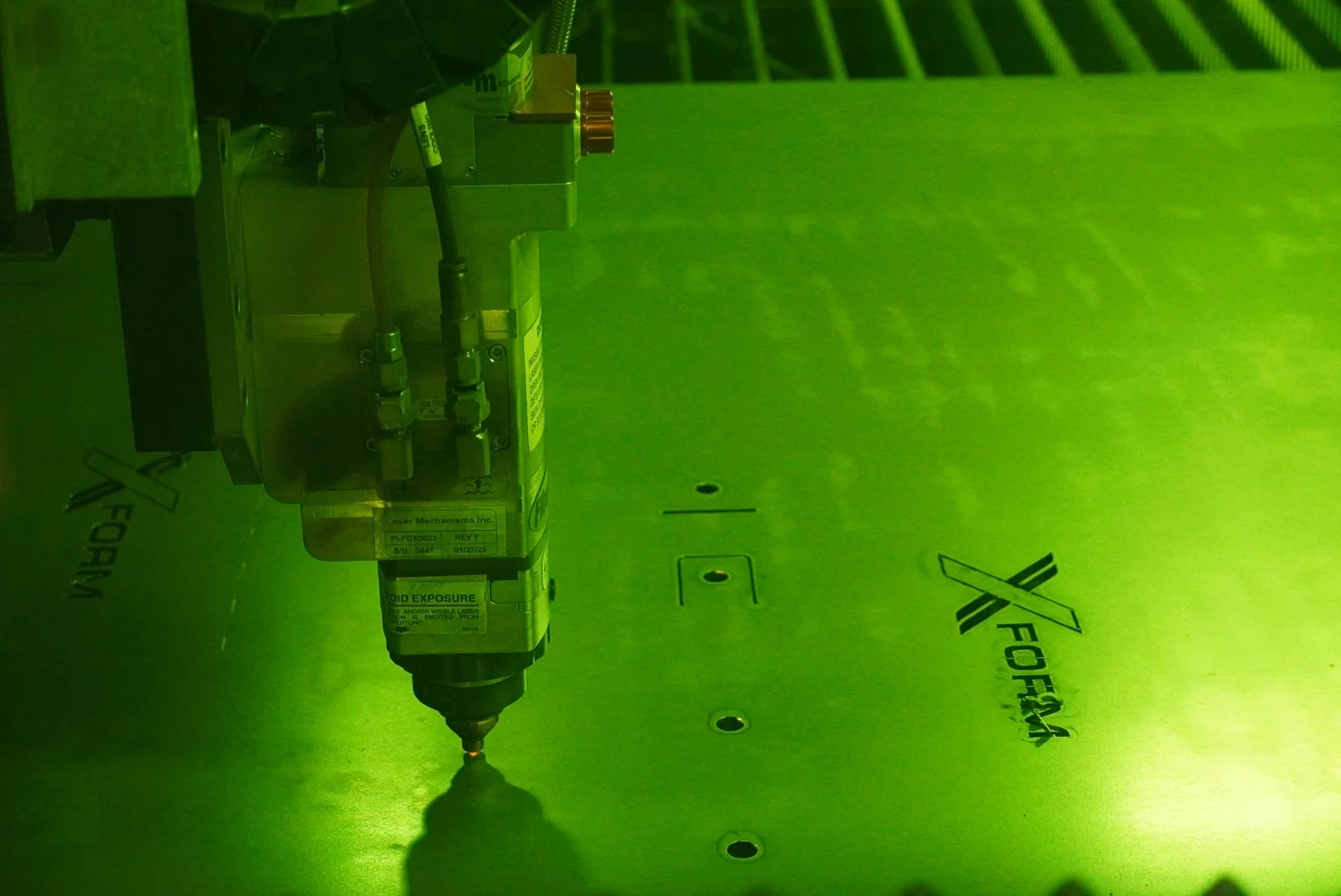

Laser Cutting

Since 1995, CI has led laser cutting innovation, setting the standard for motion control with fast, precise linear drive systems. CI’s fiber laser machines combine high-speed accuracy with a modular design that scales from standalone units to fully integrated automation cells.

With power levels up to 15kW, these systems deliver clean cuts, fast cycles, and reliable performance. Expandable automation options, including material handling, part sorting, pallet systems, load/unload stations, and storage towers maximize throughput and minimize manual labor, all while preserving flexibility.

Built to last and for easy maintenance, CI lasers are backed by vertically integrated manufacturing for assured component quality and responsive support. Whether you're a job shop, an OEM, or anywhere in between, CI lasers are engineered to grow with your operation and tight production schedules.

-

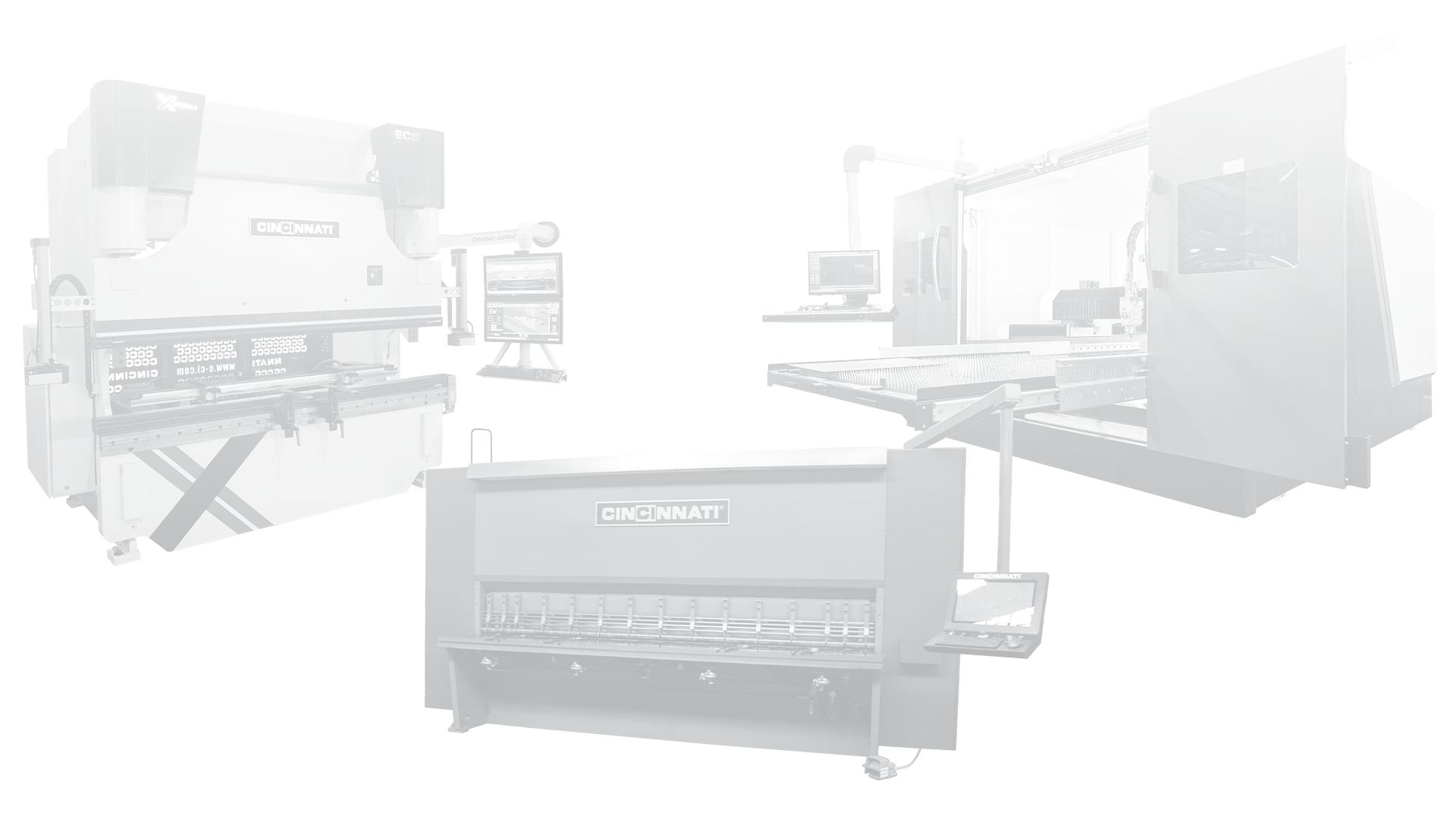

Press Brakes

One can’t think about press brakes without Cincinnati coming to mind. And CI offers one of the widest press brake ranges in the industry, spanning from 40 to 2000 tons, accommodating everything from small, intricate parts to heavy industrial components. What sets these machines apart is the use of hybrid hydraulic drive systems, which combine the energy efficiency and speed of electric actuation with the force of hydraulics.

CI’s XForm press brake models consistently deliver precision and repeatable results across a variety of production demands. With ergonomic designs, multi-axis backgauges, and customizable tooling setups, XForm adapts easily to unique shop floor needs, whether you're focused on complex geometries or high-throughput production.

-

Shears

Known for their incredible longevity, CI shears are not just machines, they’re workhorse legends. Many of these shears remain in operation decades after installation, outlasting anything else in the market.

CI shears are engineered for uncompromising reliability, ruggedness, and consistency qualities that have made them an iconic choice for fabricators who value dependability and performance.

-

Smart Technology Integration

Equipped with advanced digital capabilities that deliver real-time insights and smarter control, CI machines are future-ready. CIberDash™ provides live performance monitoring, helping reduce downtime and optimize throughput. Intuitive touchscreens, adaptive bending systems, and offline programming tools accelerate setup and improve part quality. With a clear commitment to Industry 4.0, CI ensures your equipment investment keeps pace with today’s digital manufacturing environments and beyond.

Support That Doesn’t End at Delivery

CI understands that uptime is money. That’s why the company’s service and support infrastructure is one of the strongest in the industry. A nationwide network of service technicians, remote diagnostics, and preventative maintenance programs help customers avoid unplanned downtime. The company’s deep inventory of spare parts, manufactured and stocked in the U.S., means that when repairs are needed, help is fast and reliable.

CIberDash™, the remote machine monitoring platform, gives fabricators real-time data on equipment status, usage patterns, and potential issues. This proactive approach to maintenance and performance is just one more way CI stays ahead of the curve, giving customers peace of mind and confidence in their investment.

Empowering Operators and Teams

Even the best machine is only as good as its operator. That’s why CI places a strong emphasis on training. The company offers both onsite and online training resources designed to ensure operators understand not just how to use the equipment, but how to optimize it for maximum efficiency. By investing in customer education, CI helps shops improve safety, reduce errors, and elevate workforce skills across the board.

“Very good instructors who teach well and have extensive knowledge of the subject matter.”

Oklahoma Customer

Sustainability, R&D, and Workforce Development

CI is not just building machines for today; it's shaping the future of fabrication. The company invests heavily in R&D, constantly innovating in areas like energy efficiency, automation, and smart manufacturing. Its equipment is designed with sustainability in mind offering reduced energy consumption, streamlined material use, and environmentally conscious processes.

Additionally, CI plays an active role in workforce development, supporting vocational programs and promoting careers in advanced manufacturing. This commitment ensures a steady pipeline of skilled workers and reflects a company ethos that values long-term industry health as much as quarterly sales.

Don’t Settle

Why choose one machine tool brand over another? For many fabricators, brand loyalty boils down to a level of confidence that the company behind the machine tool has your best interests in mind. In an industry where margins are tight and expectations are high; metal fabricators need partners who deliver real value. More than a machine builder, CI is a trusted ally in production excellence. With American-made quality, cutting-edge innovation, unrivaled service, and a dedication to customer success, CI offers fabricators a smarter, more sustainable path to growth.

For fabricators, the pressure is on to deliver precision parts faster, leaner, and with tighter margins. Those who focus on upfront costs when purchasing equipment will get a machine that cuts or bends. But for those who see such purchases as an investment in the long-term success of the business, the real differentiators are found in the company behind that machine and its commitment to performance, innovation, service, and partnerships.