Products

Browse our full product list of Fiber Lasers, Press Brakes, Shears, Automation, PM Presses, and more!

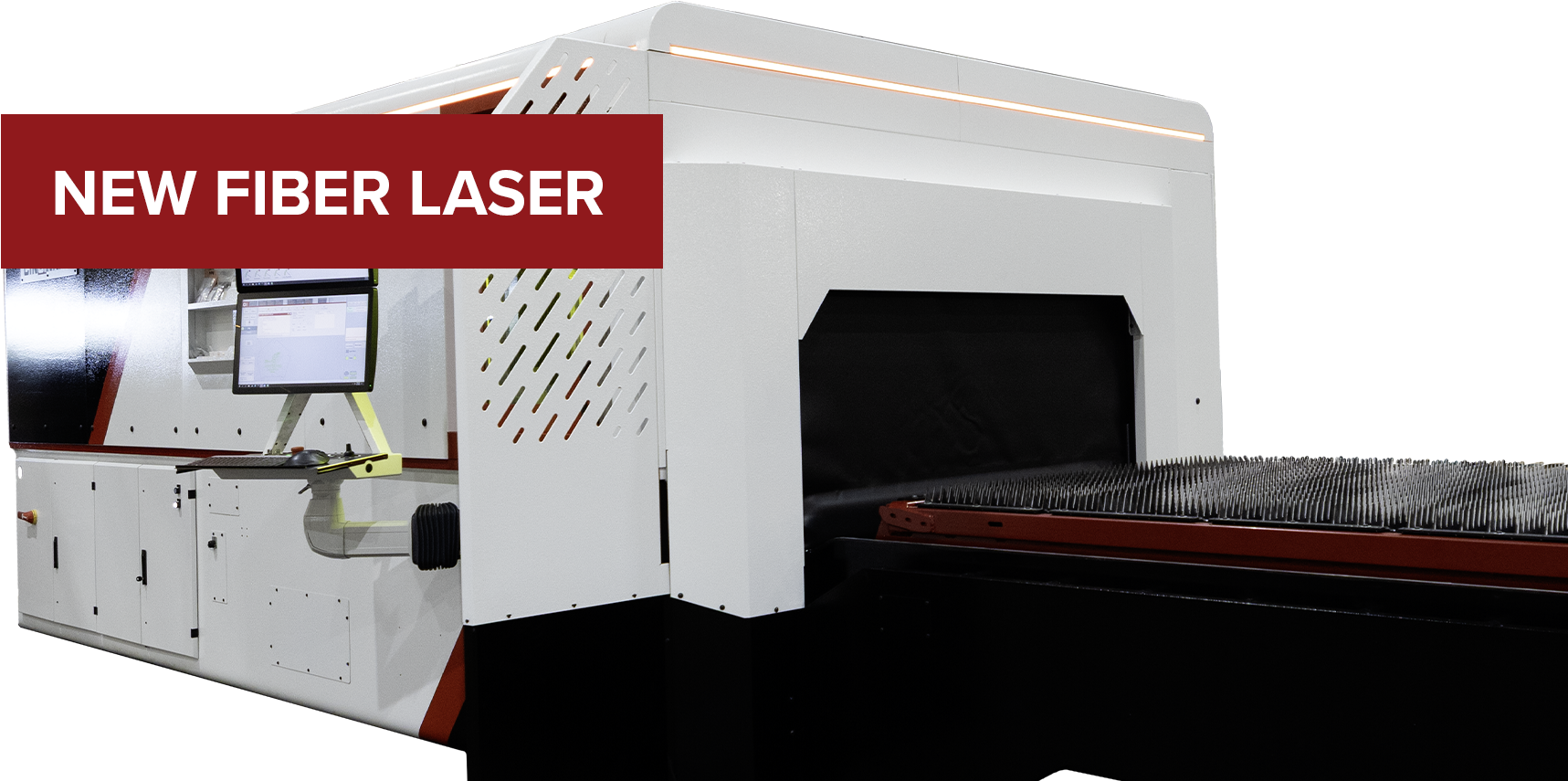

Fiber Laser Cutting Systems

-

CI FiberMax

High-performance fiber laser that combines the best features of CI's current models into a single powerhouse machine.

10kW, 12kW, 15kW

-

CI Fiber

The CI Fiber laser is the ideal entry point for businesses seeking reliable, high-speed fiber laser capabilities.

5kW | 8kW

-

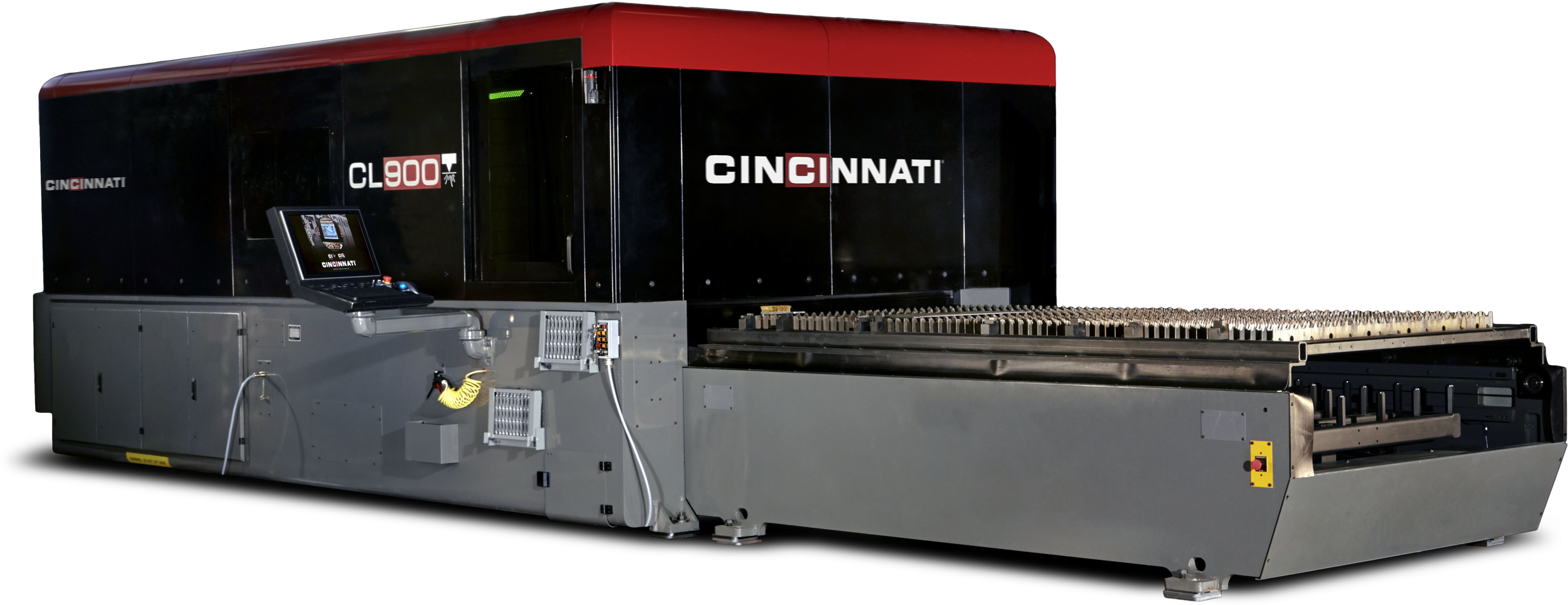

CL-900

The CL-900 Fiber Laser is a powerful, precise, and reliable laser cutting system that will help you take your manufacturing facility to the next level.

5kW | 8kW

CI Suite Software

-

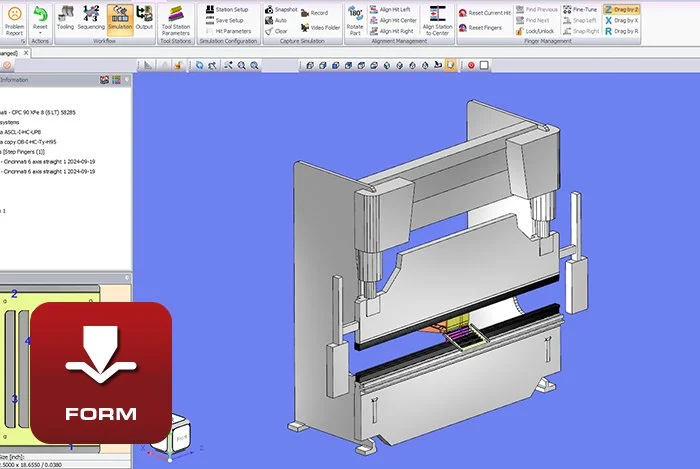

CI Form

Master your press brake offline.

CI Form provides advanced, offline press brake programming. This intuitive software allows you to simulate and program complex jobs from a desktop, eliminating downtime on the shop floor and ensuring your operators can execute flawlessly every time.

Press Brake

-

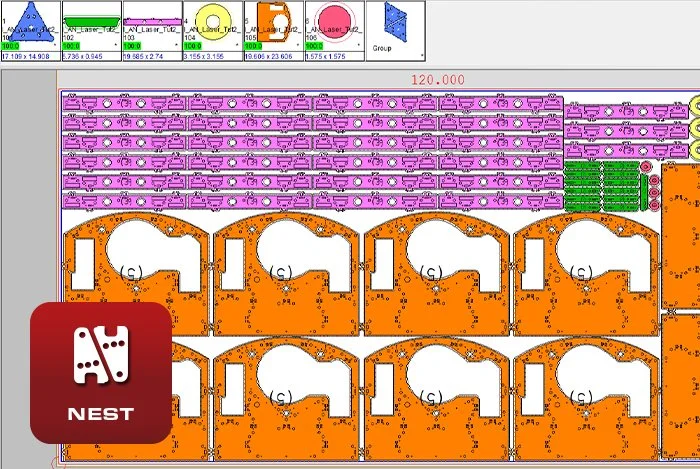

CI Nest

Maximize material. Minimize waste.

CI Nest automates the nesting of laser-cut parts, giving you the most optimized layout for your materials. This smart software reduces waste and increases efficiency, creating the machine code you need for both Cincinnati lasers and most other laser brands.

Laser

-

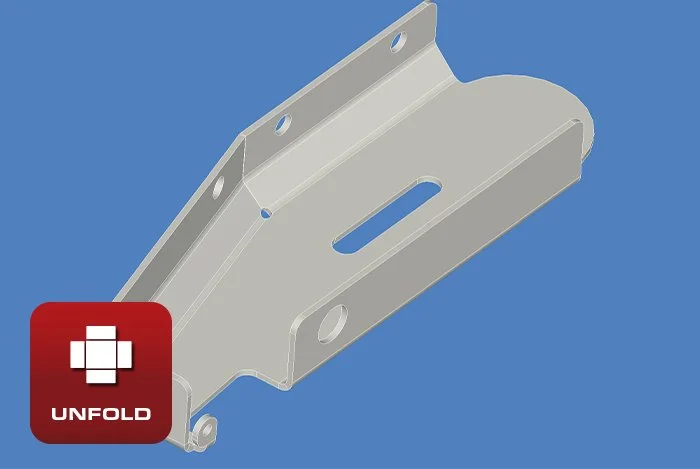

CI Unfold

Go from 3D model to flat blank—instantly.

CI Unfold accurately imports geometry from 3D models and automatically identifies the perfect flat blank. This powerful tool takes the guesswork out of the initial design phase, ensuring your project starts with the precision it needs to succeed. It's the first step in a seamless journey from design to reality.

Laser

Press Brake

-

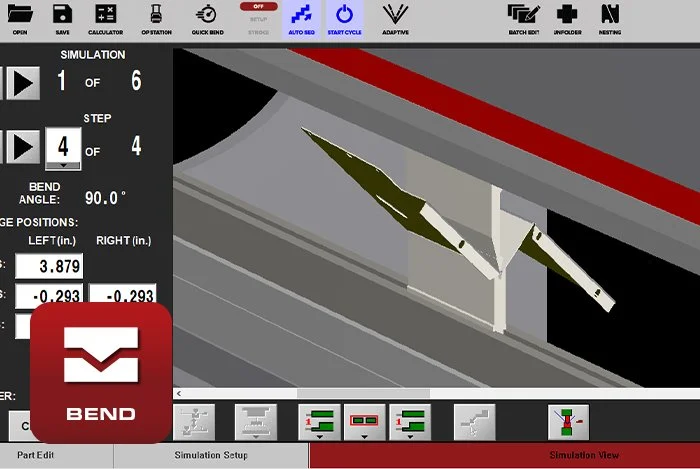

CI Bend

Program with confidence. Simulate before you bend.

CI Bend is a powerful, user-friendly tool for programming bends on a Cincinnati Press Brake. This software allows you to simulate the entire bending sequence before ever touching the machine, ensuring accuracy and preventing costly errors.

Standard on new Cincinnati press brakes.

Press Brake

-

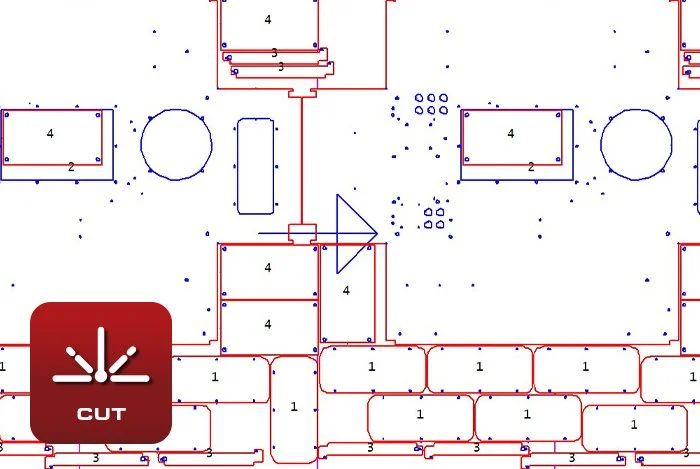

CI Cut

Go from 2D file to finished part, seamlessly.

CI Cut is a user-friendly software that transforms 2D CAD files (DXF, DWG, or IGES) into the exact machine code your Cincinnati laser needs to run. Its intuitive Windows interface allows you to quickly produce individual parts or optimized nests using the latest cutting techniques, ensuring a fast and efficient workflow from design to production.

Standard on new Cincinnati laser systems.

Laser

-

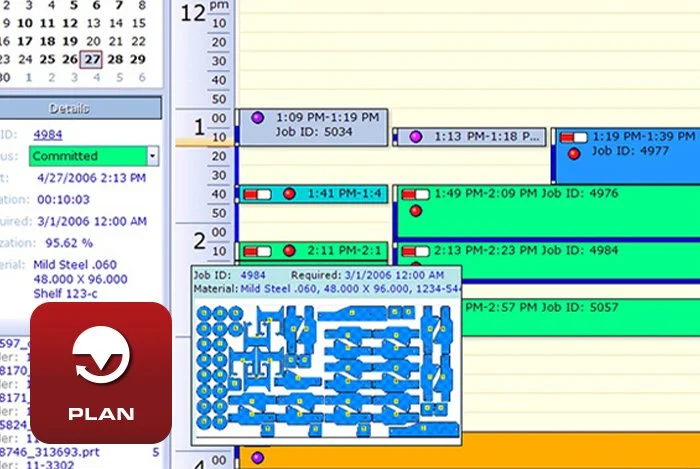

CI Plan

Automate your workflow. Optimize your time.

Stop managing schedules manually. CI Plan automates the scheduling of multiple jobs across multiple shifts and machines. This intelligent tool ensures your production runs smoothly, helping you meet deadlines and maximize the output of your entire facility.

Laser

-

CI Connect

Your real-time command center.

Get a complete view of your entire operation. CI Connect provides real-time insights into all of your Cincinnati machines, bringing Industry 4.0 and IIoT data directly to you. This powerful dashboard helps you monitor performance, identify bottlenecks, and make smarter, data-driven decisions on the fly.

Laser | Press Brake | Automation

-

CI Cast

Bring your data to life on the shop floor.

Bridge the gap between your data and your team. CI Cast is a simple, cost-effective device that displays CI Connect machine data on any video monitor in your facility. This ensures everyone from managers to operators has a clear, visible understanding of production status and machine performance.

Laser | Press Brake | Automation

Automation

-

March 400

Configure the automation to meet the needs of your shop and your business needs.

Laser Automation

-

EZ Bend

Press Brake Automation

Easily program, operate and move this cobotic cell from brake to brake.

-

SHEET FOLLOWERS

Press Brake Automation

This is the heavy lifting your press brake operators need.

-

CV SERIES SHEAR CONVEYOR

Shear Automation

Simultaneously stacks sheets and separates scrap, freeing up shear operators.

Press Brakes

-

Xform

Get ready to witness the future of precision metal fabrication with the groundbreaking XFORM Press Brake.

-

Xi

Designed for precision sheet metal bending, this versatile machine rivals its expensive competitors in terms of quality and functionality.

-

Goform

Full-featured electric bending solutions in a compact and portable package.

-

Large Press Brakes

Available in single and tandem configurations, these press brakes are a great fit for high tonnage applications of all kinds.

Shears

-

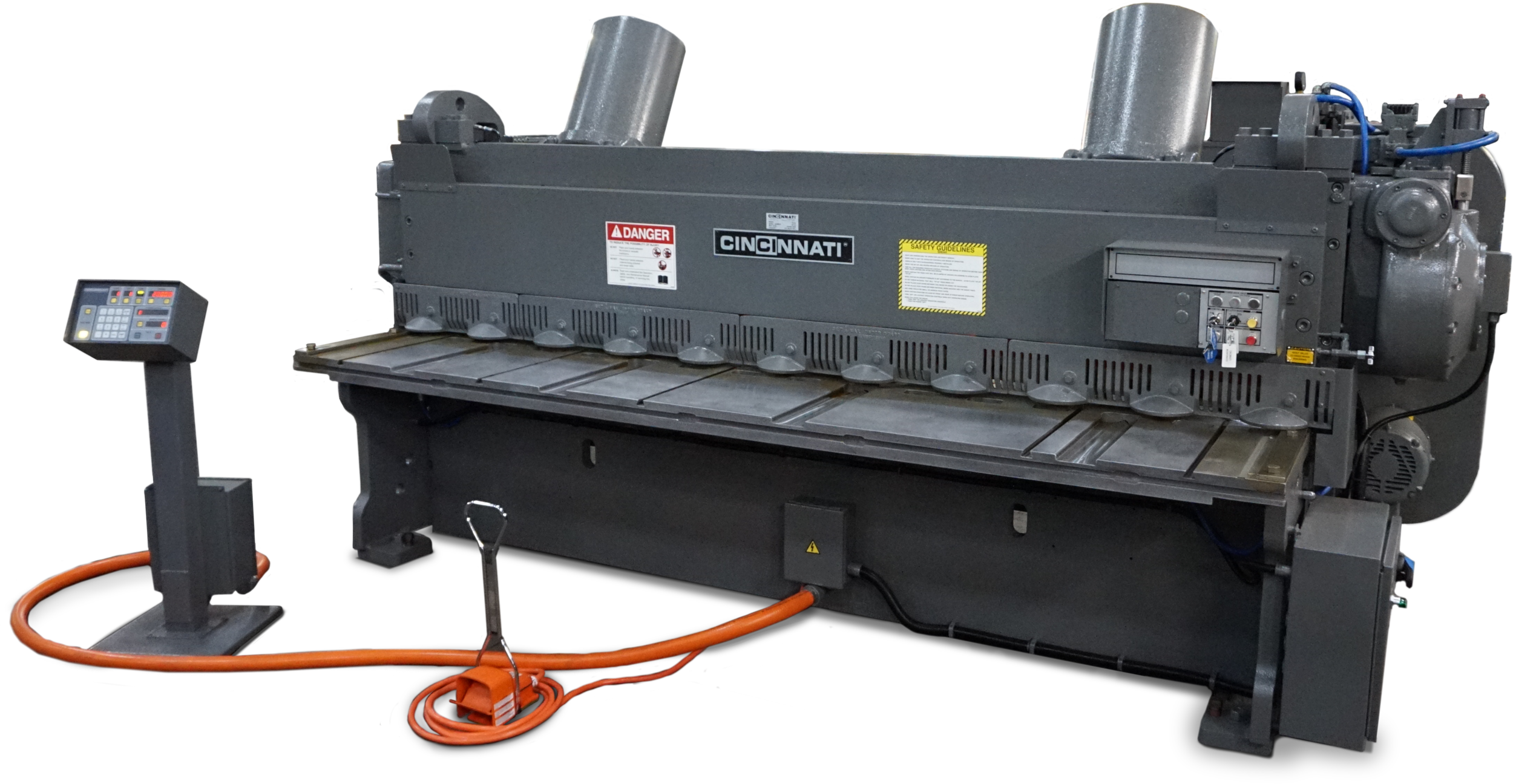

HS Series

Hydraulic power meets low-cost dependability.

-

G Series

When you’re after maximum cuts per hour, this is the shear for you.

Powdered Metal Presses

-

Parts Maker

Parts Maker Compacting Presses can produce parts with 3 lower and 2 upper levels. Key features include withdraw floating die pressing motion, precision accurate guiding and CNC controlled feed shoe.

-

Fast Set-Up

Fast Set-up Presses accept die sets with 1, 2 or 3 moving platens and produce parts with up to 4 lower and 2 upper levels. Features include computer control over critical part functions and fast setup capabilities with a removable die set.

-

Rigid Reflex

Rigid Reflex Compacting Presses feature a rugged design perfectly suited for long run and high-speed production of a wide range of parts. These presses can produce parts up to 4 lower and 2 upper levels.

-

Power Die Change

Power Die Change Presses dramatically speed job changeover allowing die sets to be changed in less than 10 minutes. This makes the CI PDC ideal for small-lot processing.

-

Rigid Restrike

Rigid Restrike presses are designed for coining, calibration, and sizing. These presses feature a rigid structure to minimize deflection, automatic dial feeder, built-in precision guiding and adjustments, part probes, and built-in checks.