Precision Cleared For Takeoff!

From aluminum skins to titanium engine brackets, CI delivers the traceability, accuracy, and oxide-free cutting required for flight-critical hardware.

Aerospace isn't about "good enough." It's about zero failure. We build machines that adhere to the strictest standards of the defense and commercial aviation sectors.

Mission Critical Manufacturing

-

Exotic Alloy Mastery

Titanium. Inconel. Hastelloy. Our high-tonnage presses and nitrogen-assist lasers process the most expensive materials without cracking or hardening.

-

Repeatability

When you are making airframe ribs, Part #1 and Part #1,000 must be identical. Our linear motor drives and adaptive crowning ensure micron-level consistency.

-

Data & Traceability

CI Connect and our software suite provide the data logging required for AS9100 compliance and complete part history tracking.

ELIMINATE SCRAP

Titanium plate costs too much to get wrong. CI Dynamic Thickness Compensation corrects for springback in real-time, ensuring the first angle is the right angle.

DYNAMIC BENDING

XFORM Series Press Brakes

Springback calculation is the enemy of aerospace forming. CI’s XFORM Press Brakes utilize dynamic thickness checks and angle measurement to adapt to material variances on the fly.

Deep Throats: Accommodate large aircraft skin panels.

Soft-Touch Fingers: Backgage systems designed not to scratch delicate aluminum surfaces.

Micron Precision: Ram repeatability of ±0.0004".

FLIGHT SPEED

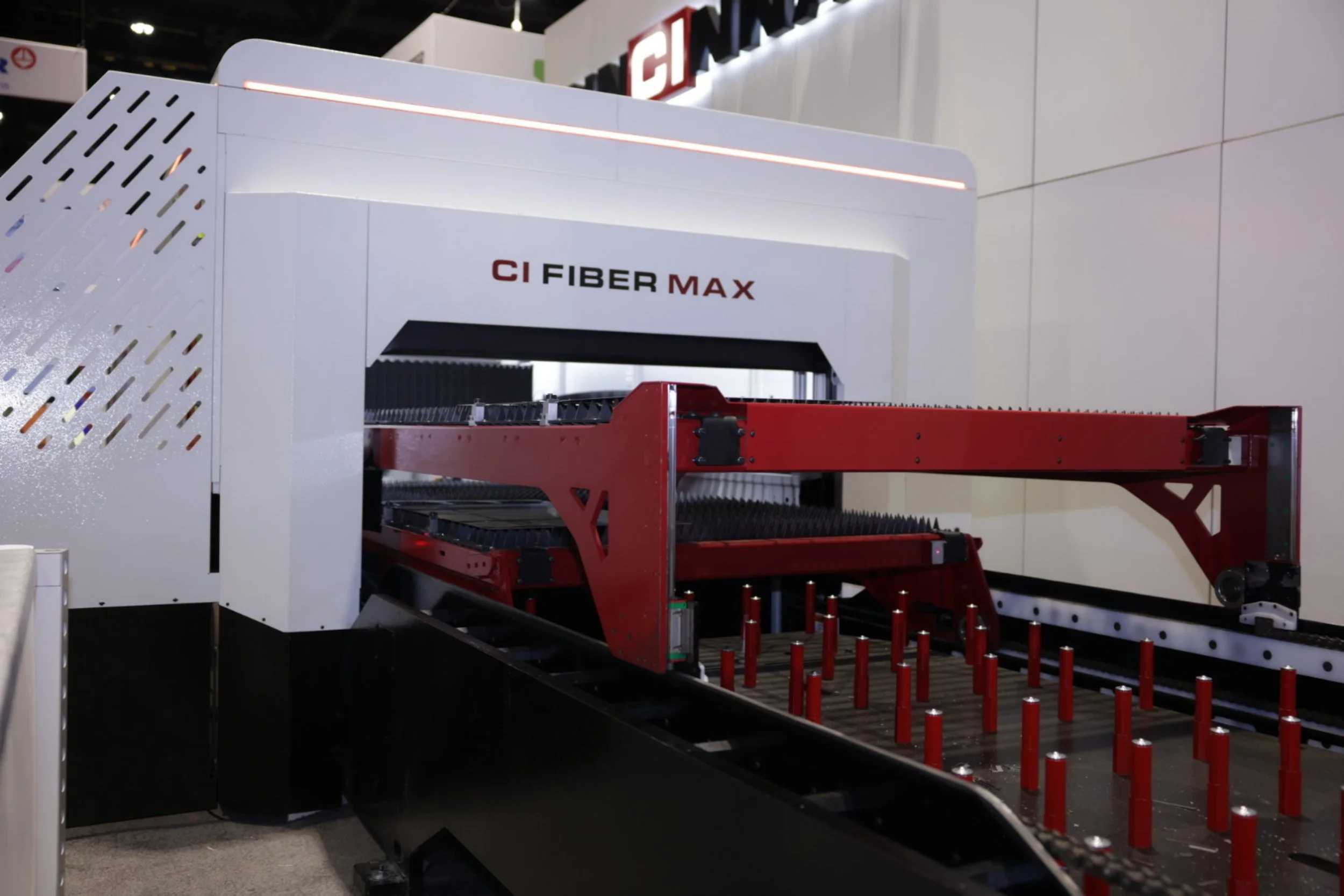

CI FiberMax Fiber Laser

Aerospace brackets and clips require speed, but also edge quality. The CLX Series delivers up to 30kW of power to cut intricate geometries in aluminum and stainless with zero oxidation.

Nitrogen-assist cutting for weld-ready edges (no secondary cleaning).

Linear motor drives for extreme acceleration on small parts.

Handle reflective alloys (Aluminum/Copper) without back-reflection damage.

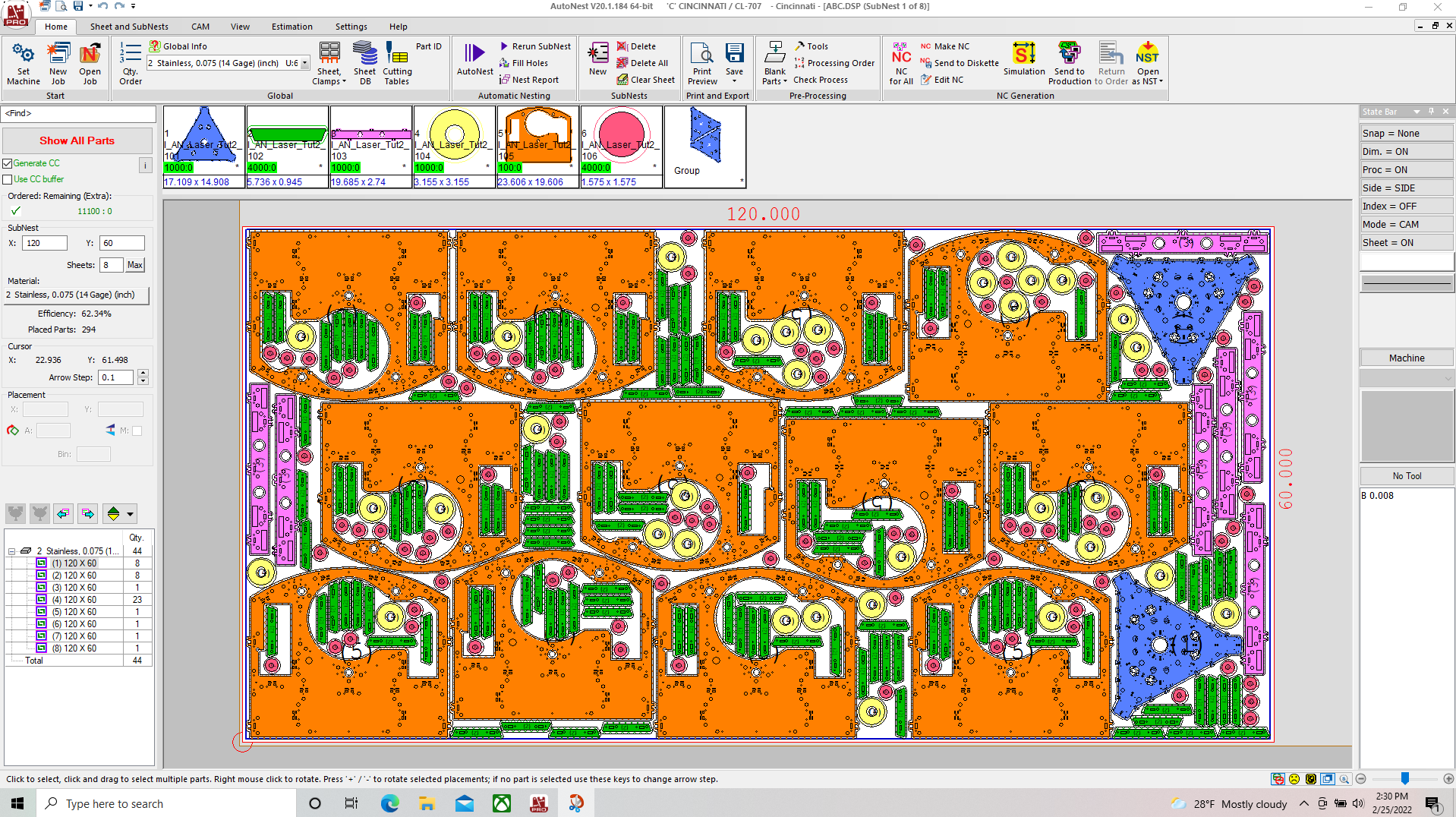

THE DIGITAL THREAD

CI Suite Software

From the CAD file to the finished part, maintain the digital thread. Our nesting software maximizes yield on expensive sheets, while our machine monitoring logs every cycle for audit trails.

Advanced Nesting to reduce Titanium/Inconel waste.

Seamless integration with ERP systems.

Remote diagnostics to prevent downtime.

Let's analyze your current requirements and recommend the perfect tonnage and automation setup.