Unlock the full potential of your fabrication process with CI Form.

The ultimate offline press brake programming software! Say goodbye to bottlenecks and wasted time, and hello to peak productivity and efficiency.

CI Form transforms your workflow by taking CNC press brake programming off the shop floor. This isn't just software; it's an intelligent solution that automates and supercharges your operations, ensuring every job is done right the first time.

CI Form is programmed with these key features

-

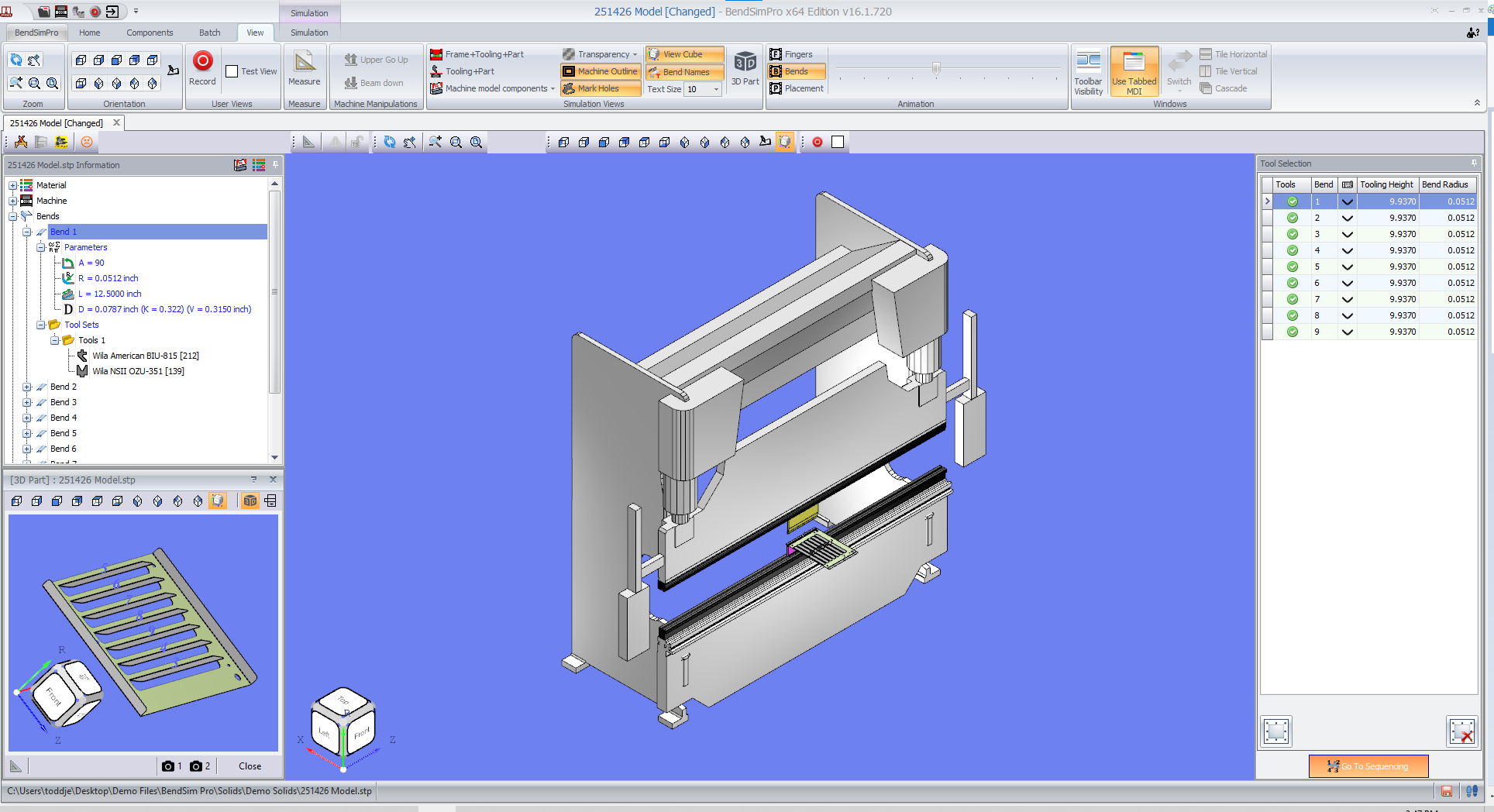

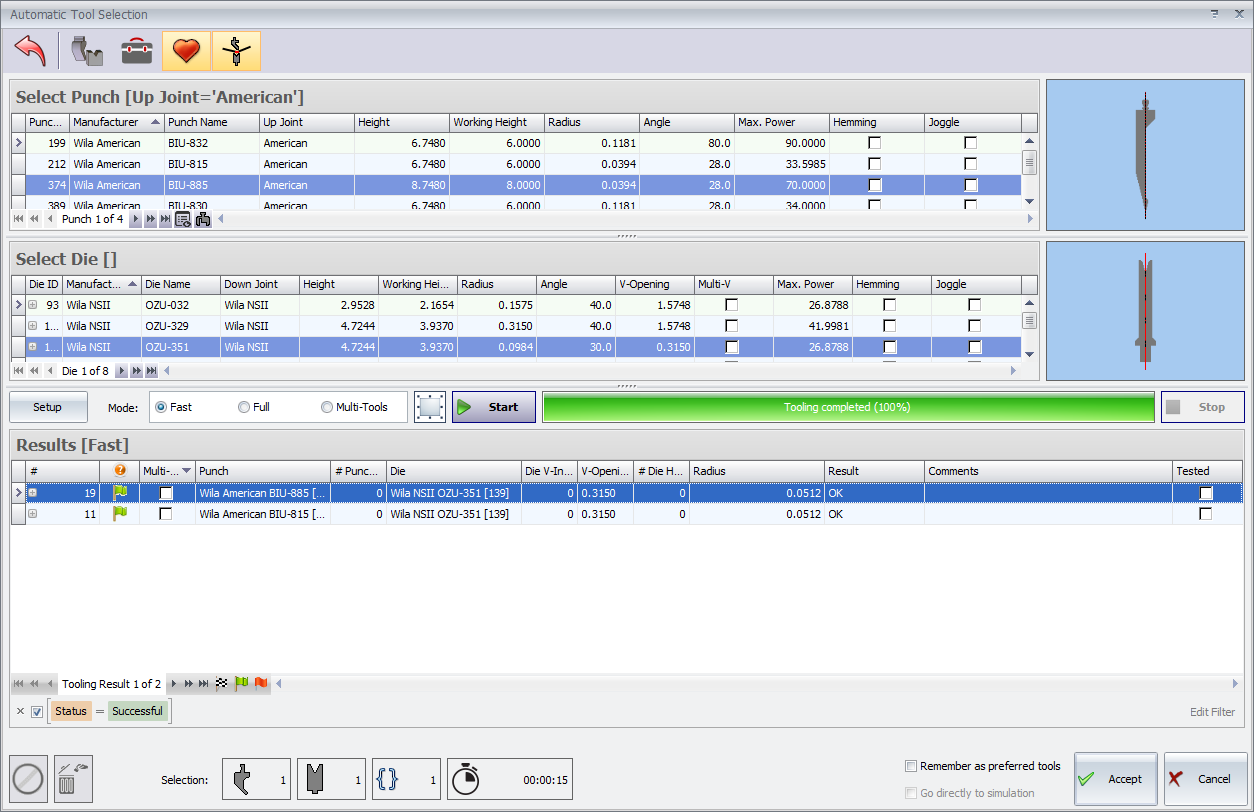

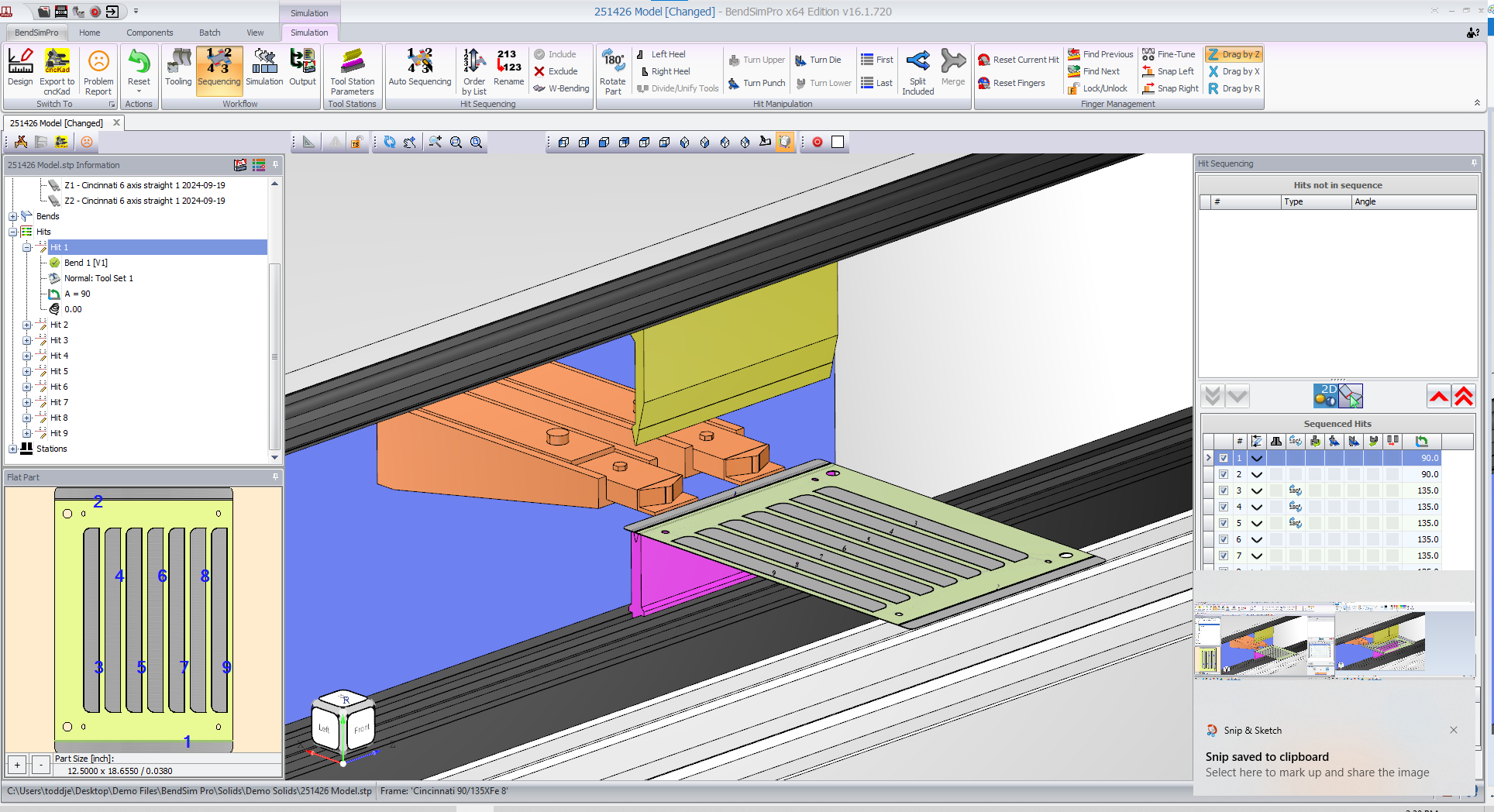

Automated Tool Selection & Placement

The software intelligently selects the ideal tooling for your job, then automatically sets up your press brake machine. This dramatically reduces setup time and eliminates costly errors.

-

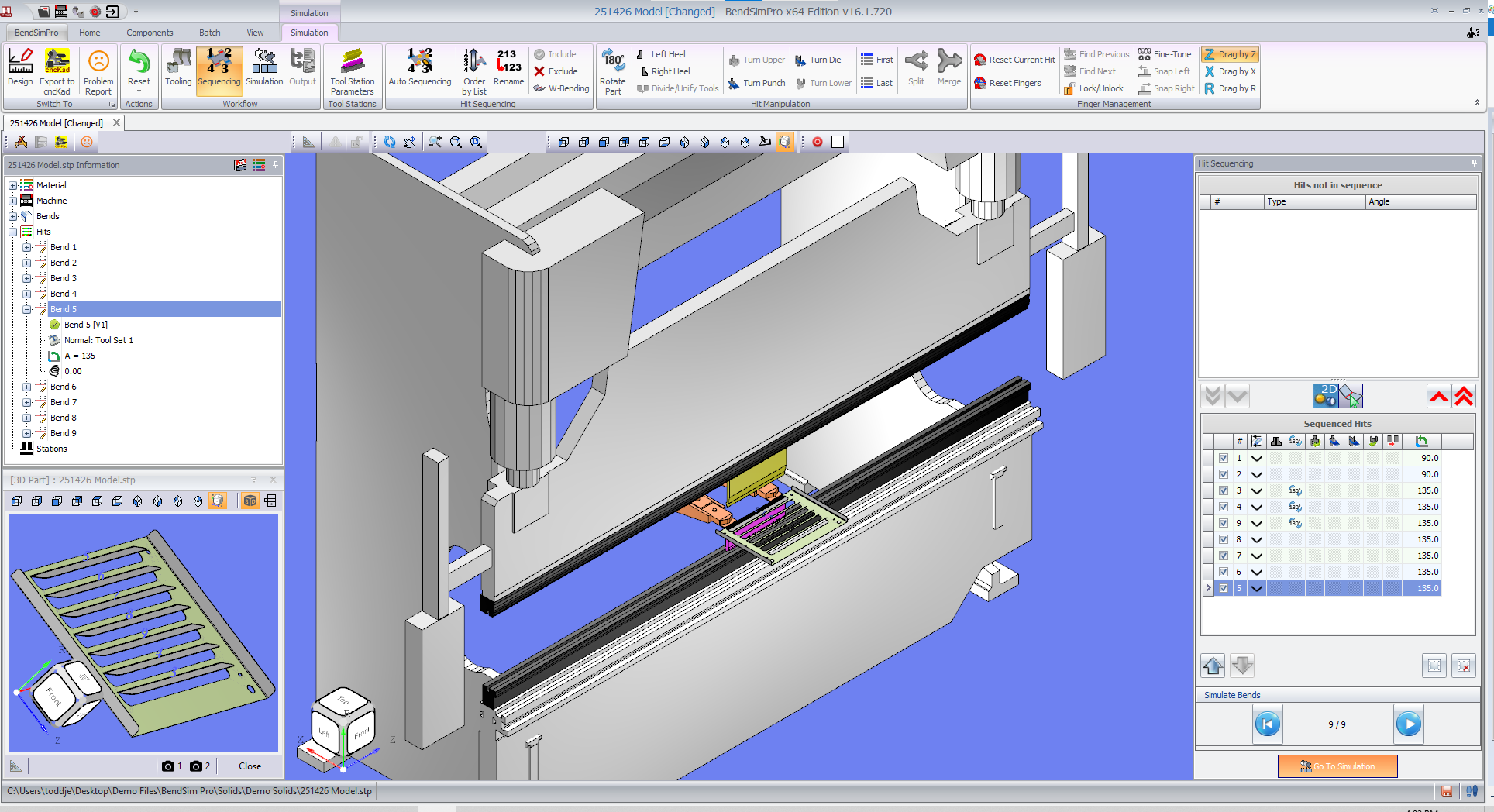

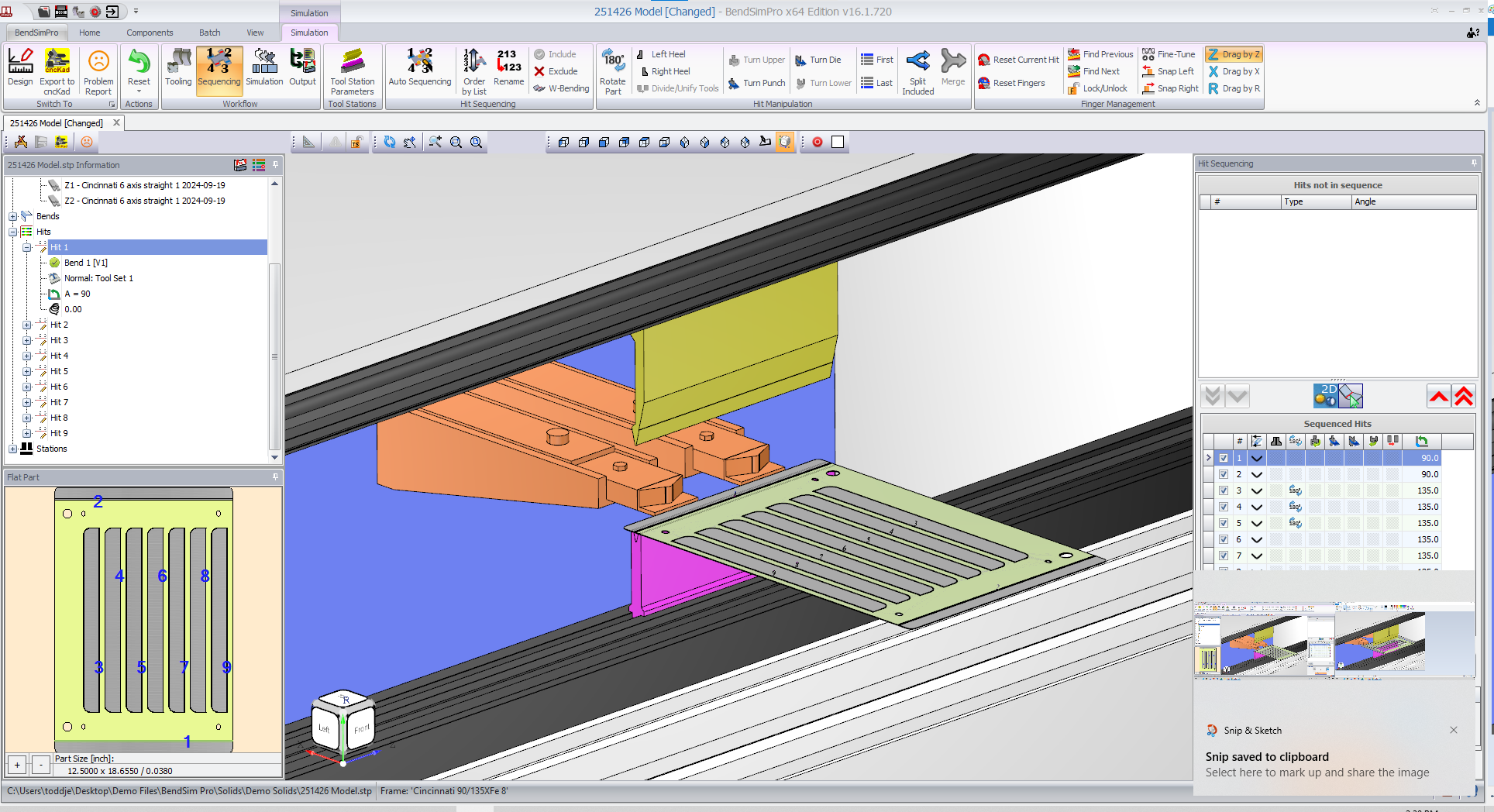

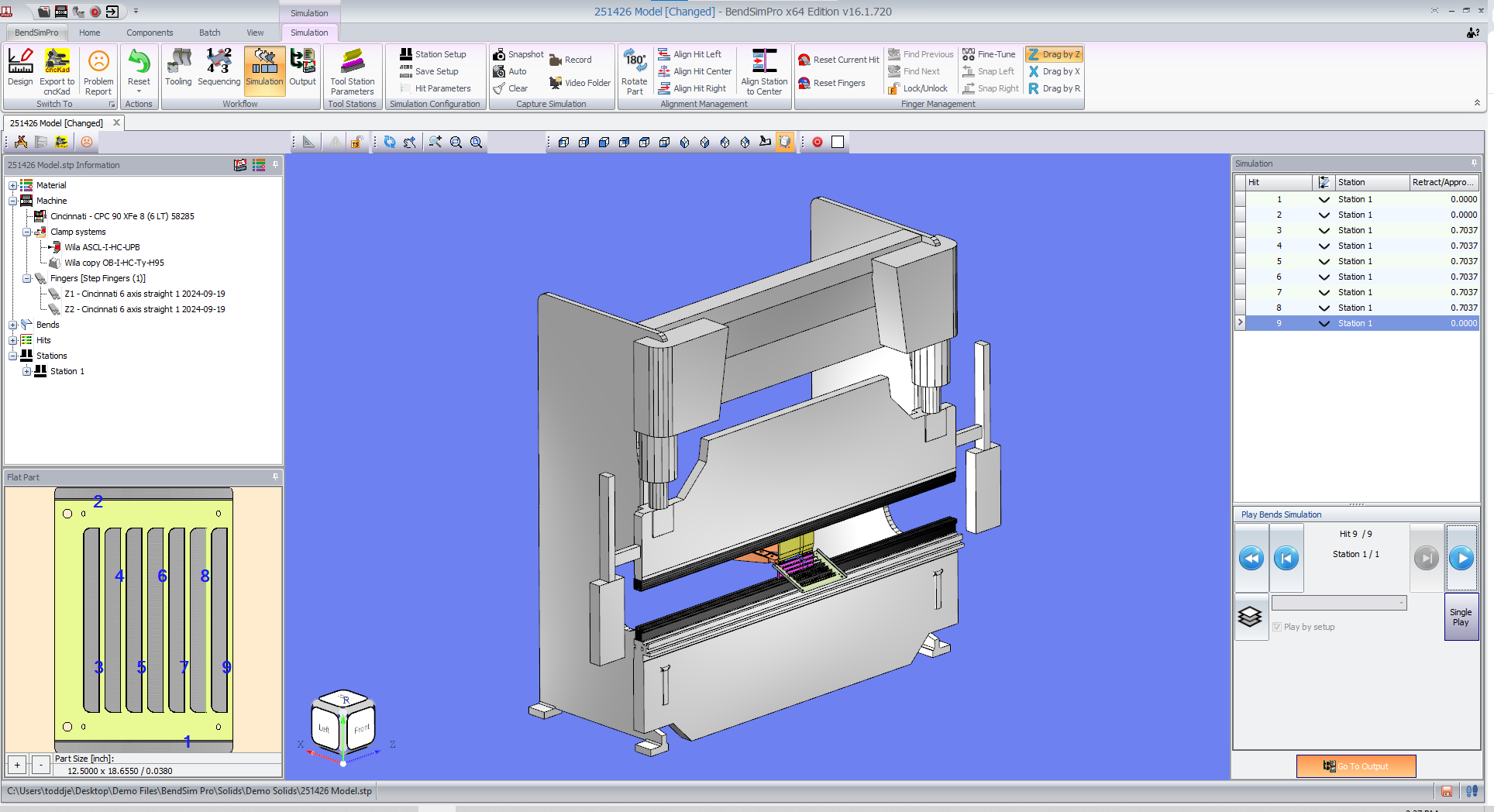

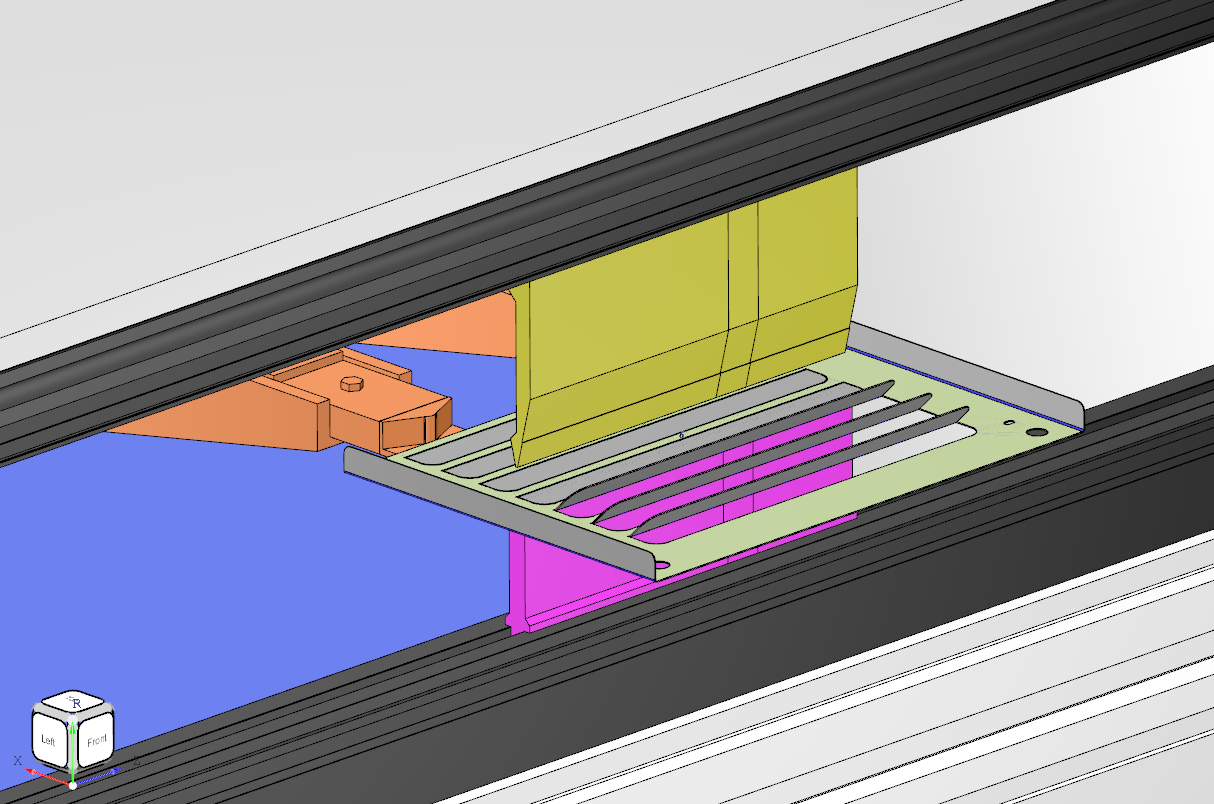

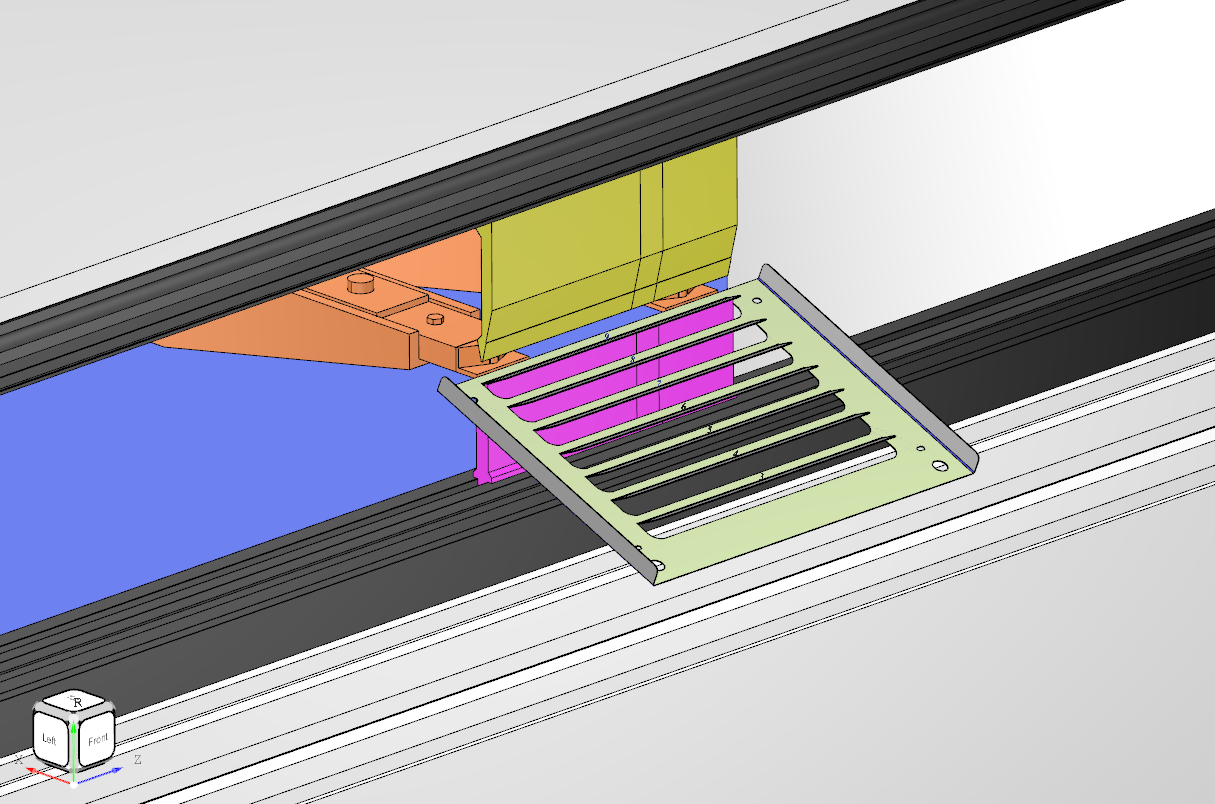

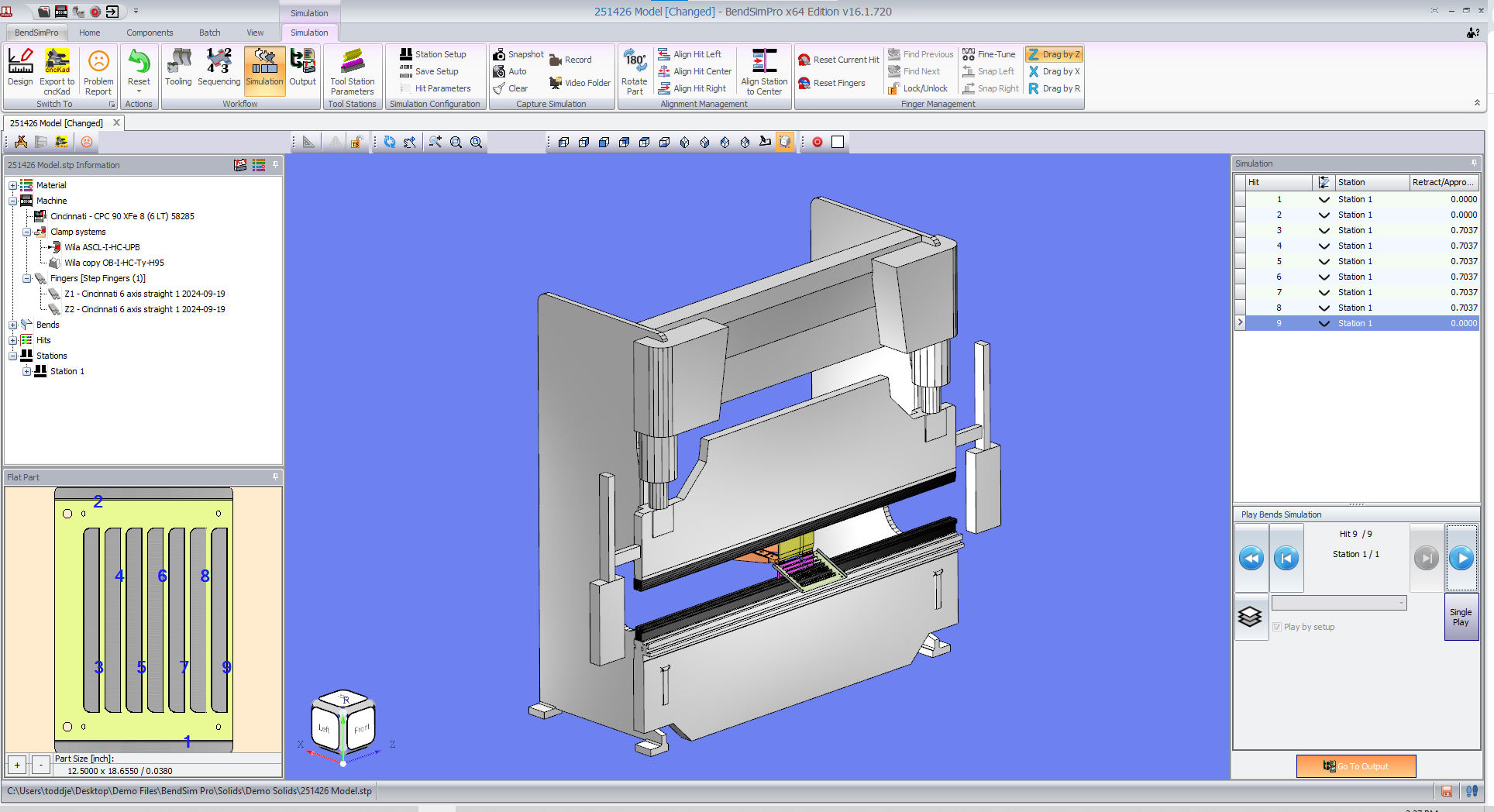

Advanced Bending Simulation

Experience the future of sheet metal fabrication with immersive 3D simulations. The software performs a thorough collision detection analysis, guaranteeing that your part can be made with a zero-collision solution—before you even hit the shop floor!

-

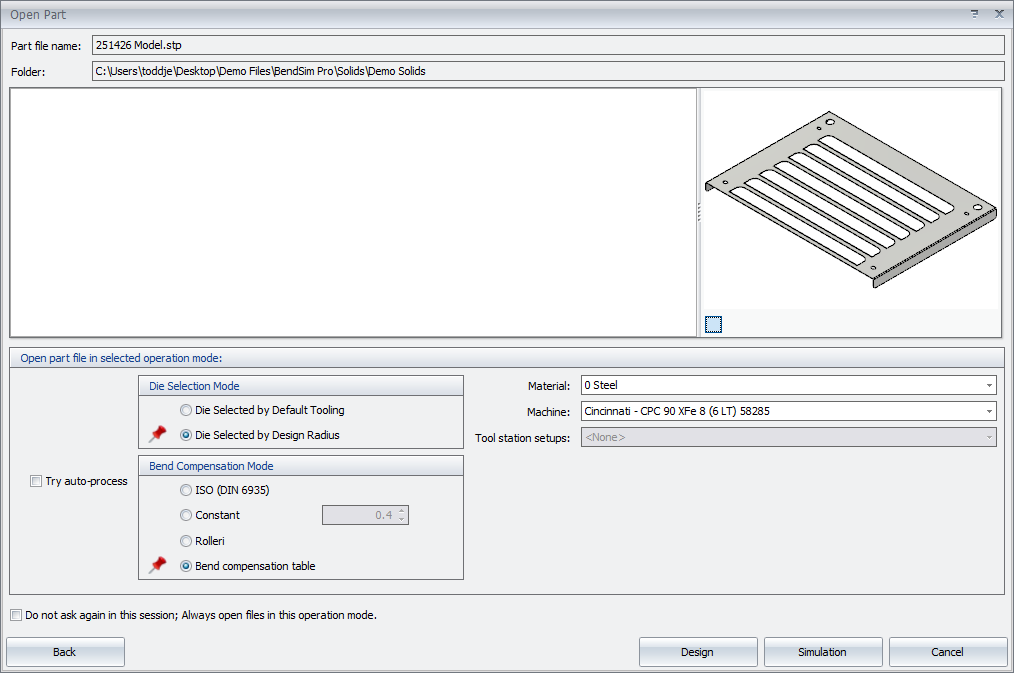

Seamless Integration

Effortlessly import your designs from all major platforms. With support for a wide range of CAD files including DXF, DWG, SLDPRT, and STEP, you can transition from design to production without a hitch.

-

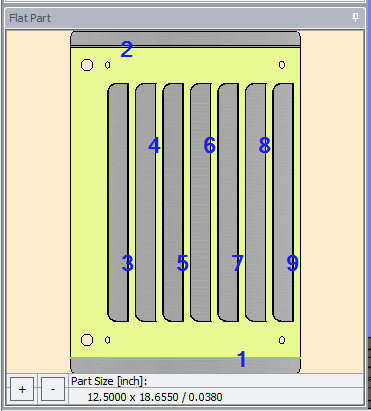

2D CAD Creation & Editing

Need to make a quick change? The integrated 2D CAD flat creation and editing tool allows you to make adjustments on the fly.

-

Intuitive Control

Use the simple "click and drag" feature to move the back gauge and set up your sheet layouts, giving you complete control with unparalleled ease.

-

Precision and Power

Optimized with a dedicated post-processor for your Cincinnati press brake, Bend Sim PRO ensures unparalleled accuracy and performance.

Supercharge your automation and achieve flawless results

System Requirements for the CI Form

Windows 10 (not Home version) PC Computer, 3GHz Processor, 64 bit required

Video resolution 1920 x 1080, NVIDIA Quadro (recommended)

50 GB available on hard drive

16 GB RAM

USB Port

Microsoft Windows networking (for optional network license)

Download CI Form Software

Full installation of CI Form V17.4.433

Full installation package of version 17.4.433 (Released October 2025).

-

CINCINNATI can assist in troubleshooting your machine through the use of TeamViewer. This software allows our support group to remotely access your control so we can better understand any problems that are occurring.

No installation required, just download and run.

For Windows XP, Embedded Standard and older, download version 12 from this link: TeamViewerQSv12

For Windows 8 Embedded and Windows IOT, the latest version can be downloaded here: TeamviewerQSv15