Is “Good Enough” Holding Your Press Brakes Back?

If your press brake operations feel like they’ve been running the same routine forever, you’re not alone. Many shops rely on familiar workflows that seem efficient enough. But “good enough” might be quietly holding your productivity back.

Press brakes are major investments, yet many fabricators still rely on machine-based programming. Every minute a press brake sits idle between jobs is lost opportunity, and according to CINCINNATI Inc. Software Product Manager Edwin Diaz, that downtime is costing more than you might realize.

“Manufacturers expect minimal downtime between jobs,” Diaz says. “But when you’re programming at the machine, that’s not always realistic. In fact, some estimates suggest that on-machine programming cuts output by as much as fifty percent.”

What’s the Answer?

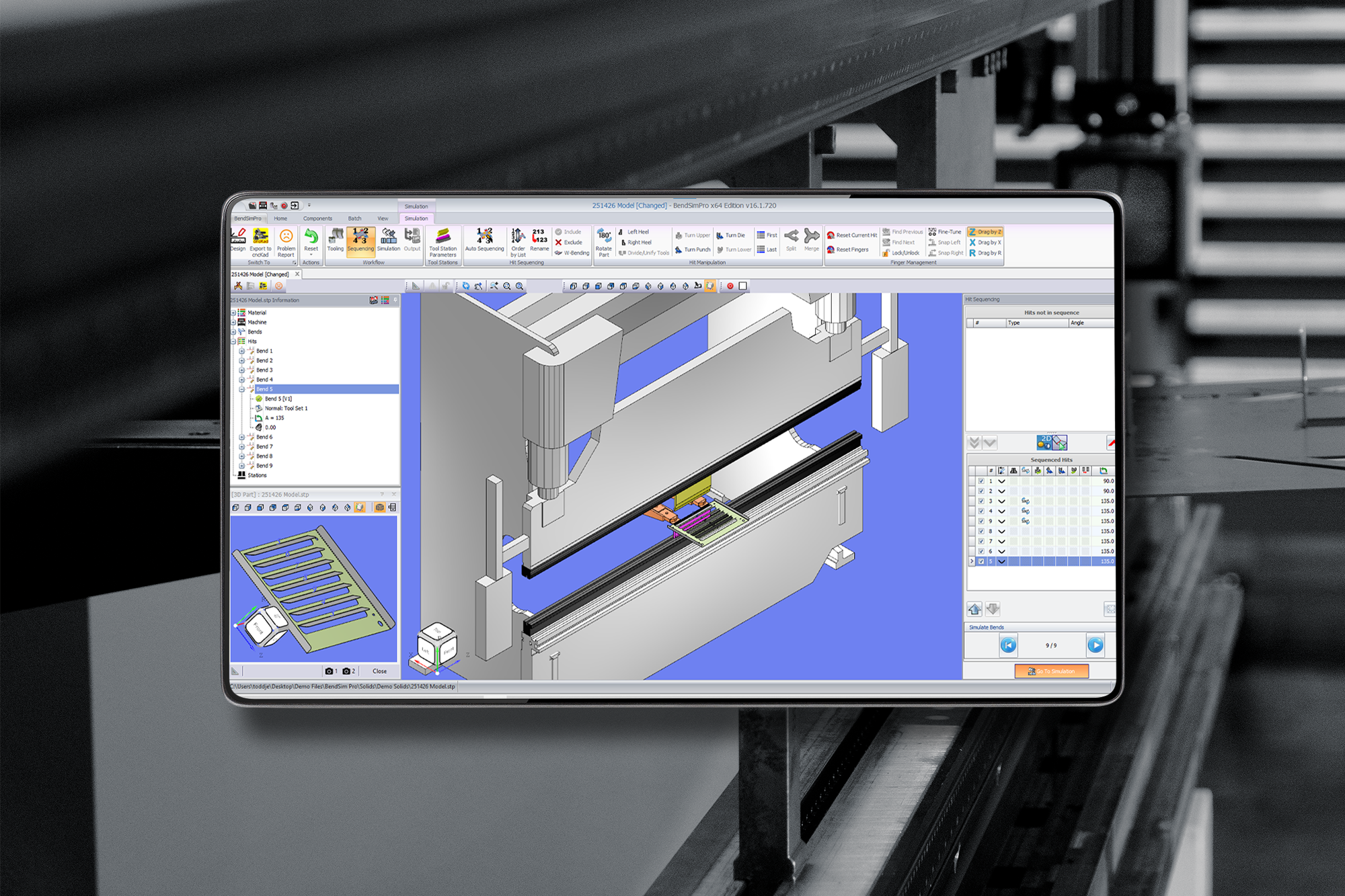

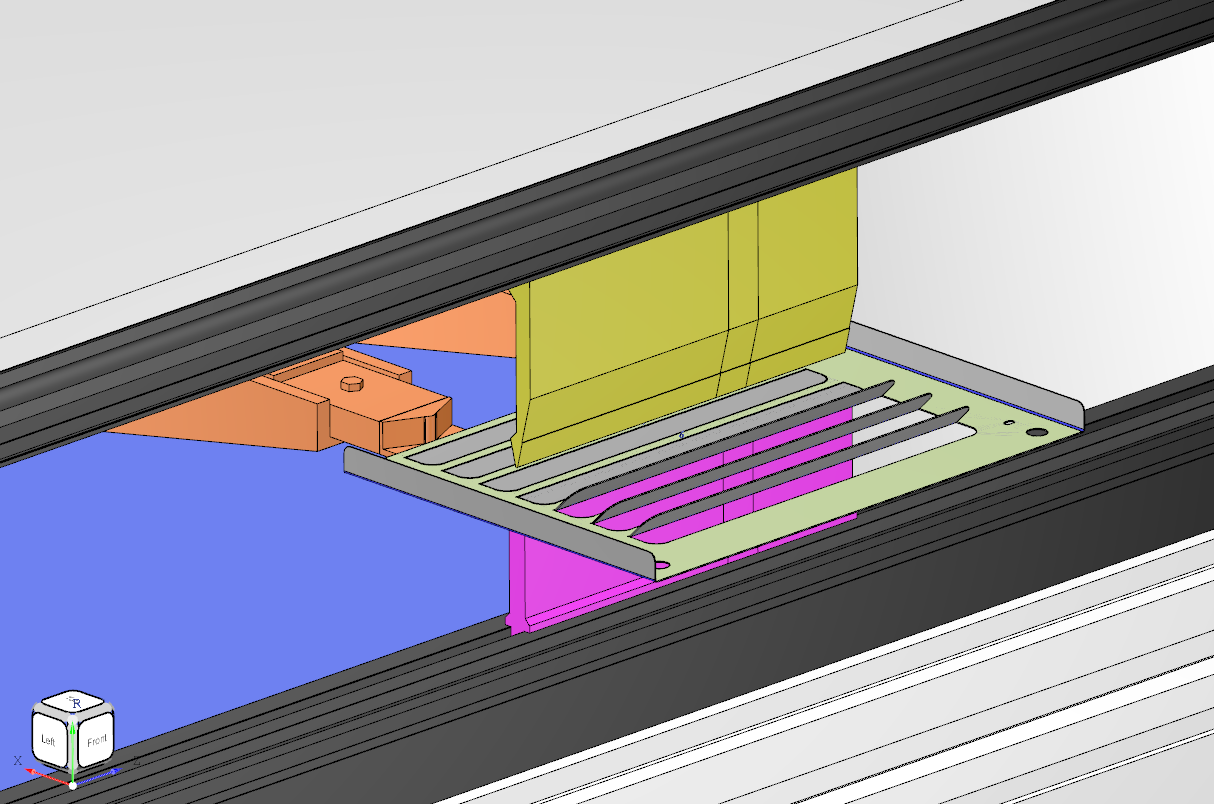

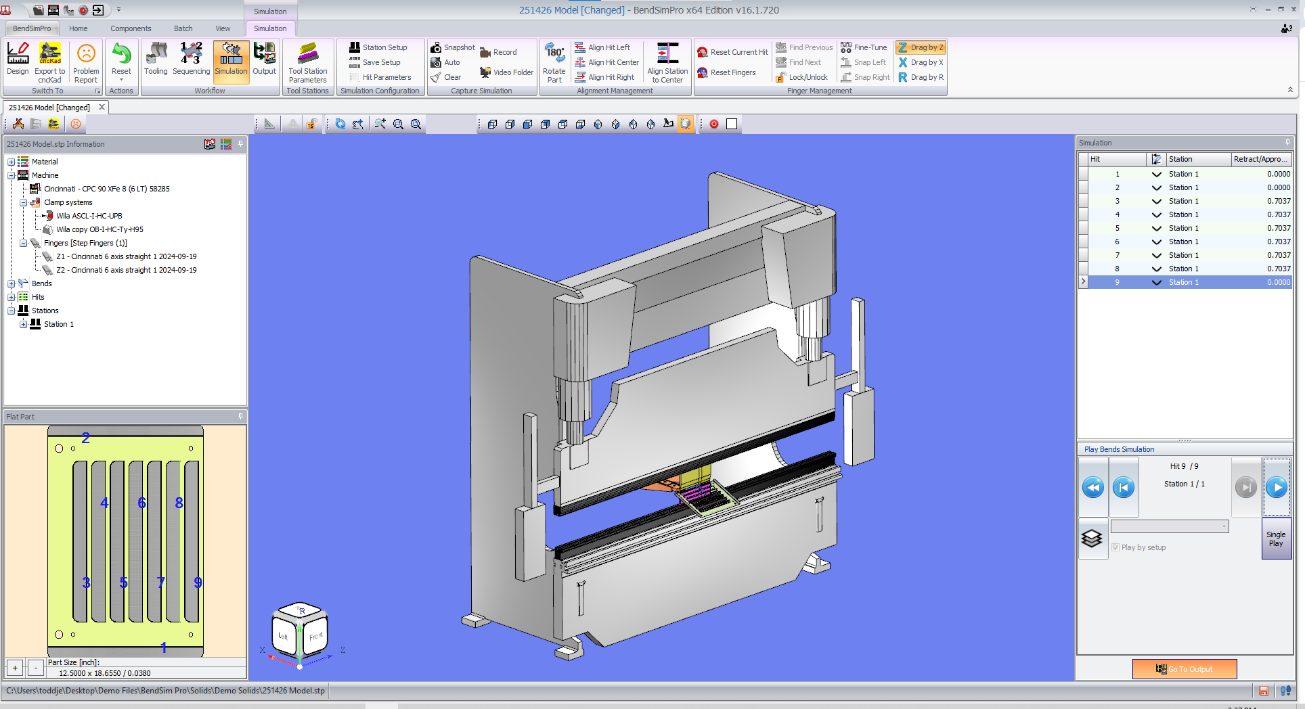

Unlike traditional programming done at the machine’s console, offline programming takes place on a separate computer. Using simulation software, fabricators can visualize each job before bending a single piece of metal. These simulations optimize bend paths, detect errors, and validate setups allowing operators to start bending the next job confident that they have the right tools and sequences. Performing production and programming in parallel reduces machine downtime, increases throughput, and queues multiple jobs well in advance.

Offline programming allows users to simulate to verify there are no collisions before sending out to the press brake.

Smarter Setups, Faster Production

Offline programming allows shops to test alternative bend sequences, optimize processes, and eliminate mistakes before they happen. “For complex parts, offline programming supports advanced strategies far beyond what’s possible at the machine,” says Diaz. “It lets shops take on more challenging and higher-value jobs.”

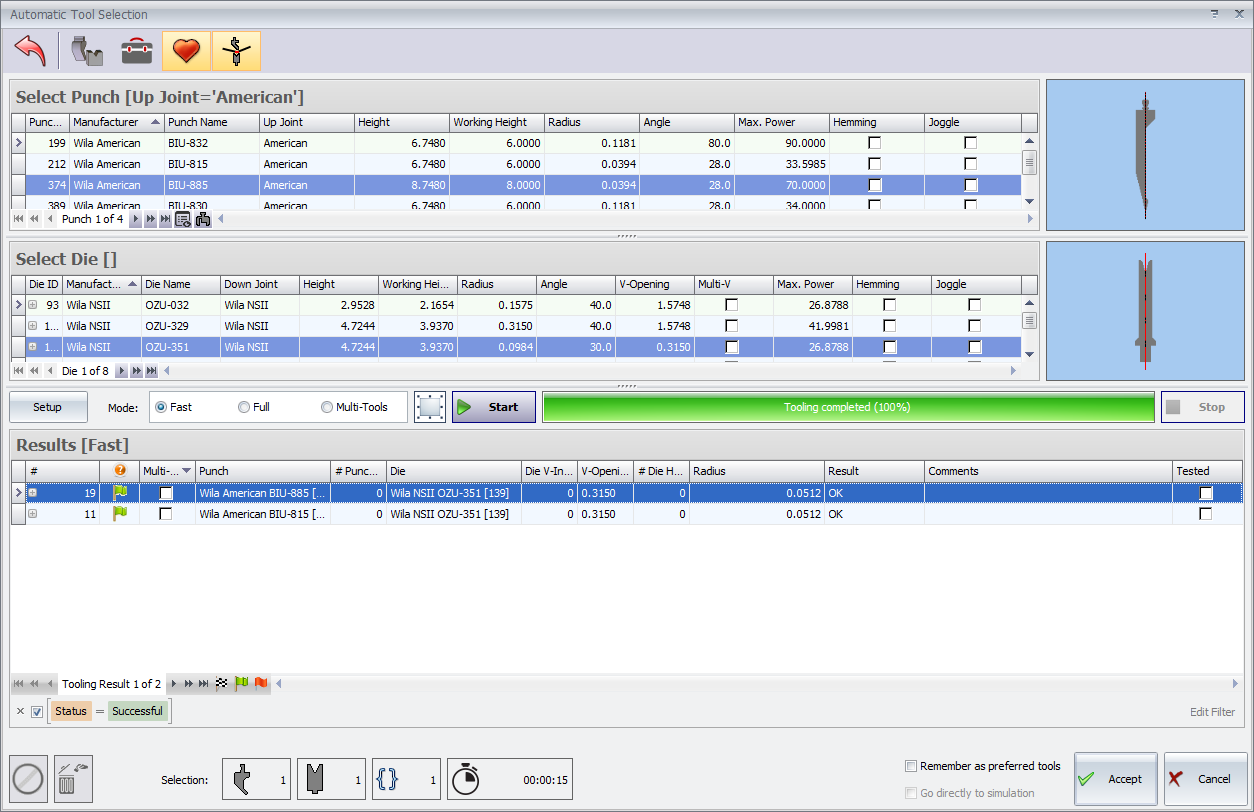

But it doesn’t stop at bend sequences. Offline software can preconfigure stage setups, tooling changes, and part orientations. It flags potential collisions, validates tool layouts, and optimizes machine settings for accuracy and efficiency. It also supports consistency. By using templates and standard elements, shops can reduce variation and boost precision, improving part interchangeability and reducing costly rework.

Most press brake providers now offer software designed for their equipment, and cross-brand compatibility is becoming more common, making offline programming more accessible than ever.

Offline programming delivers measurable benefits that directly impact the bottom line:

Faster setups – Programs load with minimal delay.

Improved accuracy – Simulations catch issues before production.

Fewer errors – Less manual input means fewer mistakes.

More flexibility – Programs can be created or modified without stopping production.

Lower scrap rates – Precise setups reduce trial-and-error waste.

“If you're spending five hours a week programming or setting up multiple parts, that’s five hours your machine isn’t making money,” said Diaz. “Offline programming boosts efficiency across multiple machines, increasing runtime and return on investment. Multiply that by your total machine count and you’ll discover that it’s a measurable payback.”

Programming lets you see the entire machine environment all in one screen, this includes machine, tools, part and sequence while simulating.

Addressing Cultural Challenges

Of course, transitioning to offline programming comes with some hurdles including software costs, training, and possibly updated hardware. Ongoing updates and support need to be factored in, and there’s a learning curve to consider.

But perhaps the biggest challenge is cultural. For veteran operators, moving from hands-on programming to digital workflows can feel like a step back. Their skills have long been rooted in intuition and on-the-fly problem-solving. Yet offline programming doesn’t replace expertise, it amplifies it. Operators still validate bends and adjust for real-world applications. Now, they can influence more programs across more machines, elevating their role from task execution to process optimization.

With a shrinking skilled labor pool and many experienced workers nearing retirement, attracting younger talent is essential. By embracing digital tools, shops can shed outdated stereotypes and appeal to a broader, more tech-savvy workforce.

Offline programming speaks to a generation raised on technology; a rising workforce that expects to employ digital tools and automated workflows in their careers. Diaz says that these workers aren’t afraid to experiment or explore software capabilities. And they're often finding efficiencies and creative solutions that previous generations may not have considered.

Advanced Tools, Real Results

Today’s advanced software integrates 3D CAD models directly into the programming workflow, enabling full simulations with collision detection, material-specific recommendations, and optimized tooling setups. CINCINNATI’s BendSim PRO creates highly accurate bend programs from digital models. It accounts for tooling constraints, backgage placement, and material properties—leading to faster transitions and more predictable results.

As part of Industry 4.0, these tools also enable real-time machine-to-software communication. Machines execute programs precisely as designed and provide performance feedback that can improve future runs.

Artificial Intelligence is emerging as the next evolution in press brake programming. AI tools are starting to analyze CAD files and automatically generate optimized bend paths, tool selections, and sequences. Eventually, these systems will adapt to individual machines and operators, learning from outcomes to continuously improve performance. Predictive maintenance, real-time optimization, and smarter material handling are all on the horizon.

Despite its sophistication, offline programming isn’t just for high-volume operations. Small shops with frequent part changeovers will see measurable gains. For example, those who switch programs for 10 customers a day and spend just five minutes setting up each job, are losing nearly an hour of production daily. Over time, that adds up. Reducing setup time means faster turnarounds and fewer errors - key advantages in a competitive industry where every minute counts.

Offline programming chooses the best tool available from within your inventory to make the part.

The Bottom Line

If your current process “gets the job done,” change might not feel urgent. But if your goals include increasing output, reducing waste, or expanding capabilities, offline programming could be your competitive edge.

To help ensure a smooth transition to offline programming, follow these steps:

Audit your process – Pinpoint inefficiencies offline tools can solve.

Choose compatible software – Ensure it works with your machines.

Engage your team – Involve operators and programmers early on.

Invest in training – Make sure your team knows how to use the tools.

Digitize your tooling – Accurate data equals accurate programs.

Pilot first – Start small and refine your approach.

Standardize workflows – Document best practices.

Iterate and optimize – Use performance data to improve continuously.

“Even just five minutes of setup per job, spread over 10 jobs a day, adds up fast. That’s a full hour your machine isn’t producing. Over a week, a month, a year that’s serious lost potential.” says Diaz. “But offline programming isn’t just about speed, it’s about unlocking the full value of your machines and your people.”