Automate Your Brake

Operation EZ-ily

Transform your operation with EZ Bend, the easy and innovative way to integrate automation. Free up your press brake operators to focus on complex bends ensuring a smooth and efficient operation for even the most complex tasks.

Effortlessly place metal parts inside the press brake for precise bending within designated allowances. Boost productivity and efficiency like never before with EZ Bend.

Revolutionize Automation in Your Operation

EZ Bend is a game-changing solution for manufacturing processes, offering the ability to seamlessly move from press brake to press brake. With its turn-key operation, EZ Bend simplifies the production workflow, saving time and resources. Its user-friendly interface makes it easy to learn and operate, ensuring a smooth and efficient operation for even the most complex bending tasks. Whether it's adapting to changing production needs or streamlining operations, EZ Bend provides the flexibility and convenience needed to meet the demands of the modern manufacturing industry. Say goodbye to complicated setups and hello to a simplified and hassle-free bending experience with EZ Bend.

Ease of Programming

One of its key strengths is its highly intuitive programming interface, which eliminates the need for complex coding or advanced skills. With EZ Bend's easy-to-follow steps and user-friendly interface, anyone can program it with minimal training and effort. This makes it the perfect solution for companies looking to increase efficiency without sacrificing quality.

Mobility

The EZ Bend system is compatible with all types of press brakes, allowing for seamless integration and versatility in your manufacturing processes. It can be easily implemented to enhance your operations. This flexibility ensures that you can take advantage of the benefits and capabilities of EZ Bend, regardless of the specific type of press brake you have in your facility.

With EZ Bend, you can streamline your manufacturing process and optimize productivity,

no matter the equipment you use.

Cobot vs Robot

Cobots are designed to share a workspace with humans, placing a strong emphasis on safety, versatility, and user-friendliness. Cobots are about making automation easier than ever before for businesses of all sizes.

Industrial robots are typically autonomous machines created for tasks that involve repetitive, highly precise activities, often requiring minimal human involvement.

EZ Bend: Unlock the Future of Press Brake Automation

Embrace the exhilarating world of automation with EZ Bend, unlocking boundless opportunities that will catapult your operations to dazzling new heights. Yes, navigating the waters of automation comes with its challenges, but imagine overcoming them and reaping the incredible rewards!

Bending & Welding: Easy Automation

By streamlining and automating the bending process, EZ Bend enhances productivity, efficiency, and accuracy. Experience smoother workflows, faster production cycles, and consistently high-quality bends. With EZ Bend, you unlock the true potential of your operation, maximizing output while minimizing operator fatigue.

Take control of your automation journey with EZ Bend. Embrace the future of bending technology and elevate your operation to new heights. Discover the power of effortless integration and witness the transformative impact that EZ Bend brings to your press brake operations.

Key Features

-

Double Blank Detection

Before making the first bend on each part, the cobotic robot utilizes a double blank detector to confirm that only a single piece has been picked up from the inbound stack. This built in verification step offers quality assurance needed to run your press brake operations.

-

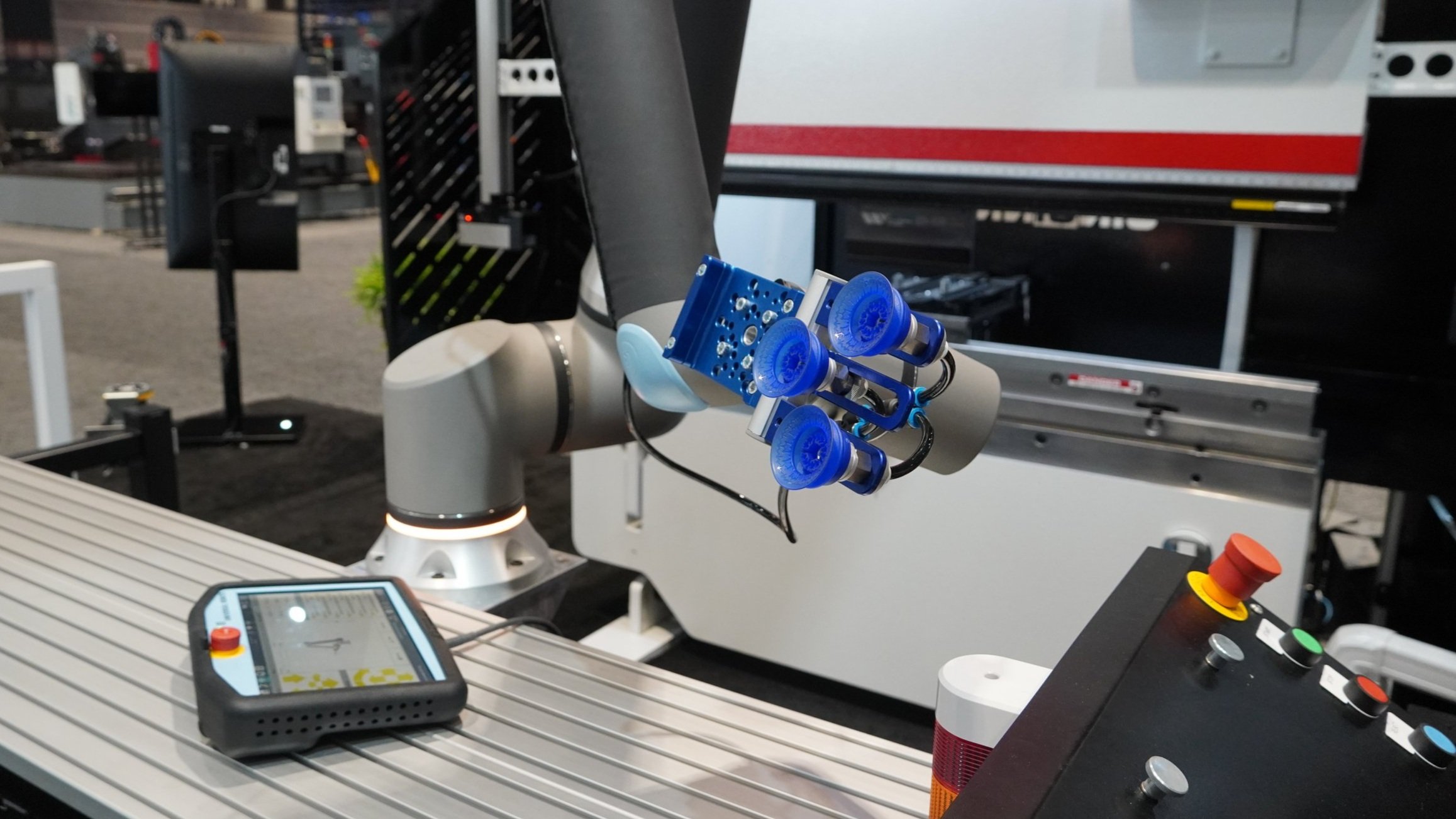

Pneumatic Part Gripper

The EZ BEND is equipped with specialized pneumatic suction cups designed specifically for handling metal. These suction cups ensure secure, yet gentle handling of your materials, eliminating the risk of marking or damaging the parts.

-

Guarding System

The work area is guarded by optical scanners. Without physical barriers you’ll have easy access to the EZ BEND and press brake. When a person breaches the perimeter of the work zone the robot slows down. If the person backs away, the robot returns to normal speed.

-

Multitasking

The EZ Bend allows one operator to tend to multiple presses simultaneously, maximizing the efficiency of the production process. This enables the operator flexibility during the production.

-

Safety

Traditional press brake operations often require operators to position their hands close to the bending area. Using EZ Bend can greatly reduce the risks associated with working in close proximity to the dies.

-

Offline Programming

Have you tried to automate and failed? With the EZ Bend, programmers with press brake experience can easily learn how to program and operate the machine, eliminating the need for a mechanical engineer proficient in manipulating 3D models.

-

Extended operation

Operators have the flexibility to set up and run the machine during off-shift hours or over the weekend. This enables increased productivity and efficiency as the machine can continue operation even outside regular working hours.

-

Automation

One of the benefits of the EZ Bend is that it allows for automation without permanently tying up your press brake with physical barriers. You can switch back to manual operation at any time without requiring extensive modifications to your setup.