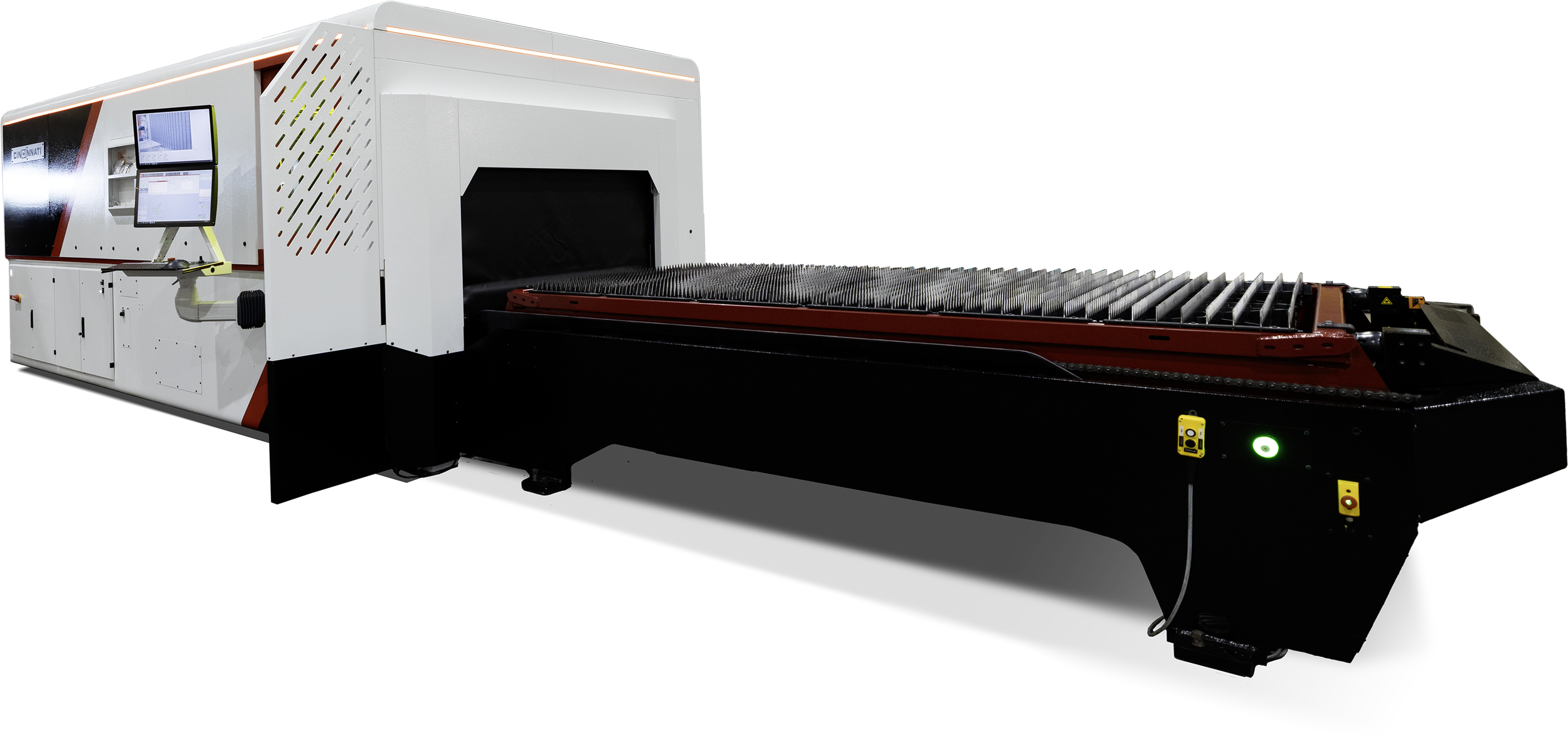

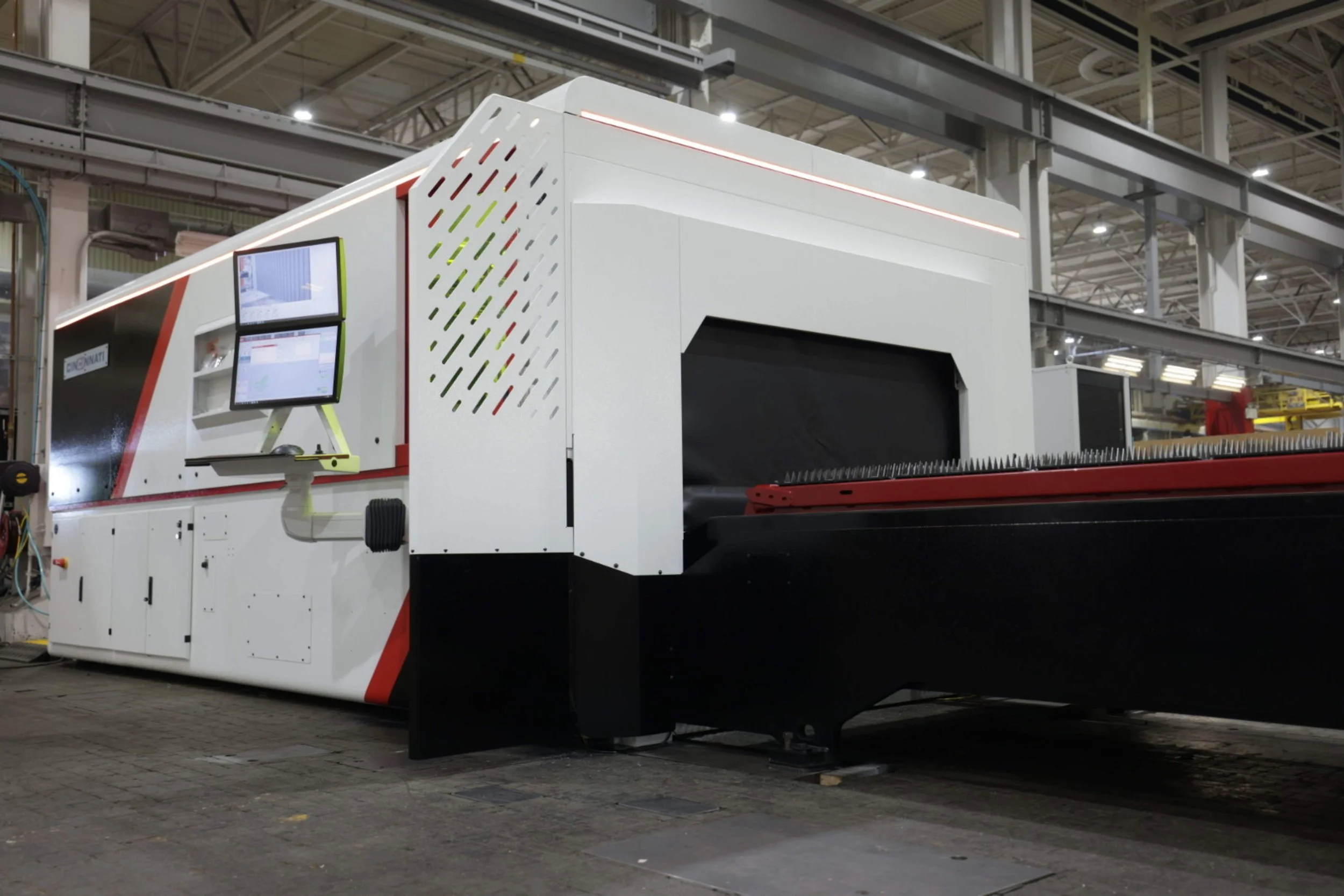

The Ultimate Evolution in Fiber Laser Technology

The brand-new CI FiberMax is a leap forward in laser cutting, engineered to be the single, most powerful, and versatile fiber laser in our history. We’ve taken the best features from our current lineup and combined them into one formidable machine, designed to elevate your productivity and redefine what’s possible.

Unmatched Performance & Speed

The CI FiberMax is a high-performance fiber laser that combines the best features of CI's current models into a single powerhouse machine. It boasts an industry-leading 11-second dual pallet exchange, a proven linear drive motion system, and a redesigned exhaust system for superior performance. With a robust all-steel frame and an operator-centric design featuring dual 24" monitors and advanced software, the CI FiberMax is built for maximum productivity, reliability, and ease of use.

Power Sources: 10kW, 12kW, 15kW

Table Sizes: 3015 and 4020

![Photos 60fps_4[v1].jpg](https://images.squarespace-cdn.com/content/v1/5e66928f9f87a05becdce88d/3f606da9-2748-4190-87a6-c9b91e77f714/Photos+60fps_4%5Bv1%5D.jpg)

A culmination of decades of expertise, built to empower your business with speed, precision, and unrivaled reliability

The CI FiberMax is equipped with these key features

-

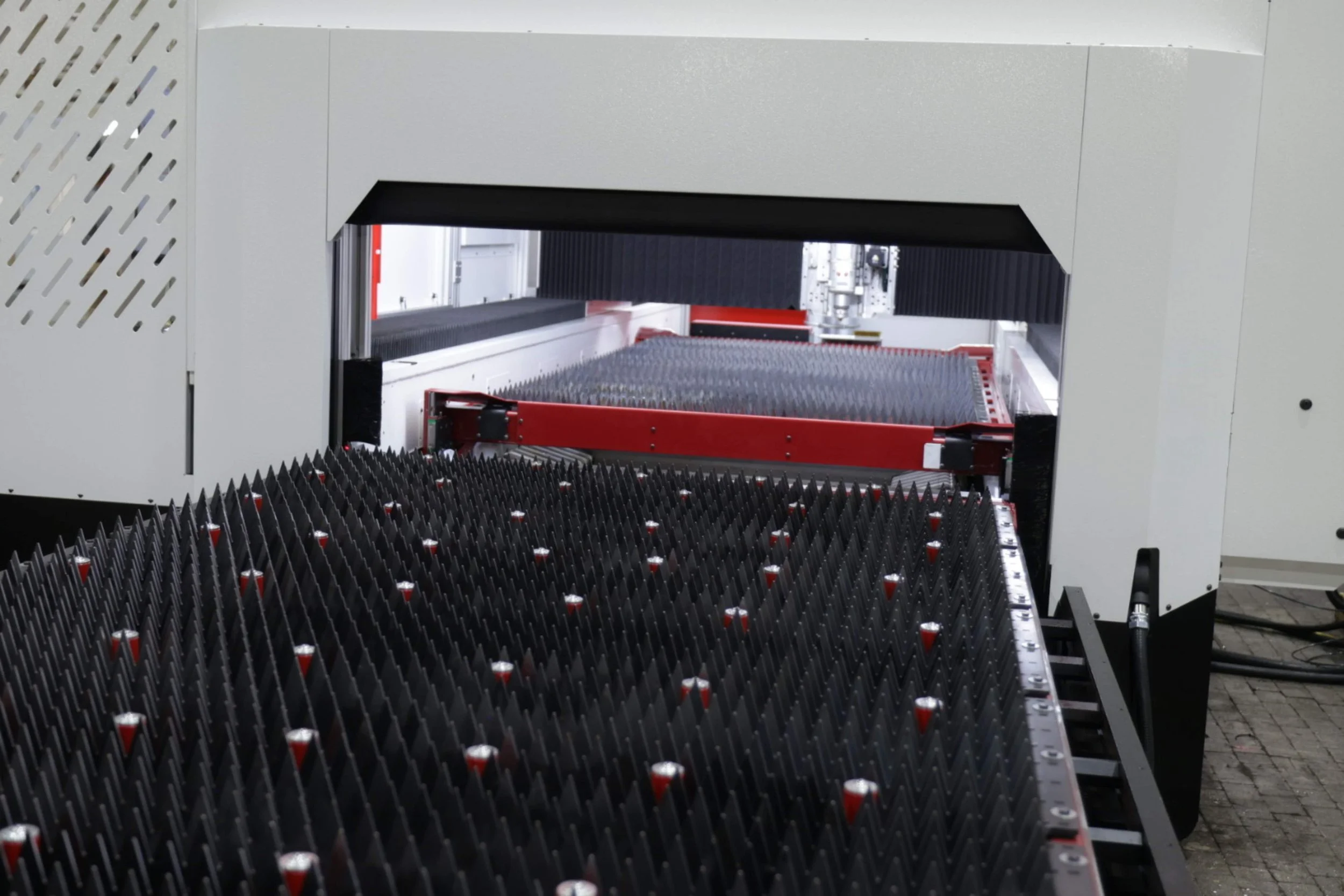

Industry-Leading Dual Pallet Exchange

Experience an incredible 11-second pallet exchange time, the fastest in the industry. Our unique design ensures that both pallets maintain the same cut height, eliminating the need for recalibration and maximizing your uptime.

-

Industry Standard Table Sizes

Available in both 3015 and 4020 table sizes to accommodate a wide range of sheet metal dimensions.

-

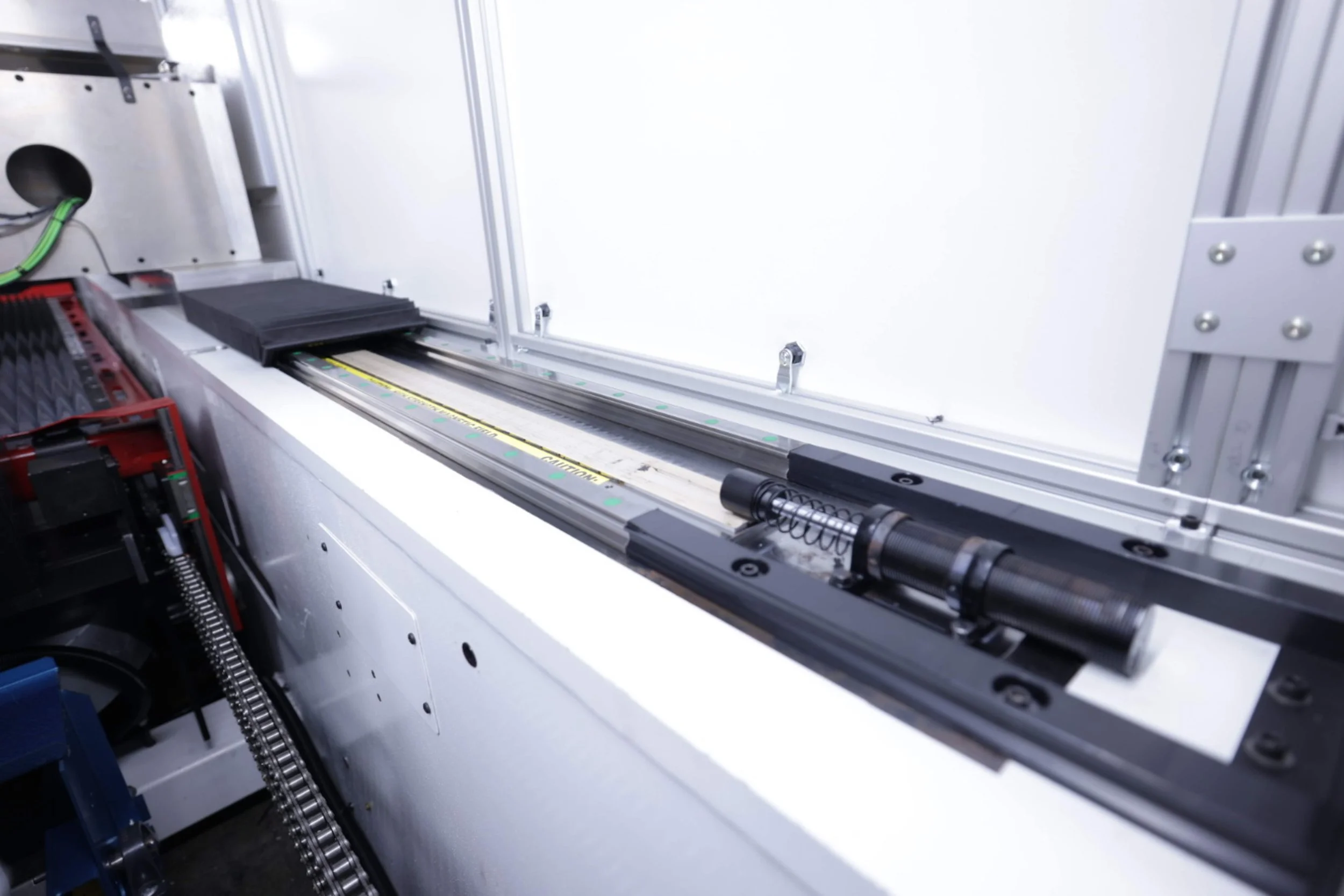

Linear Drive Motion System

Our 4th generation Linear Drive, a system we pioneered in 1996, delivers proven reliability and exceptional performance with rapid speeds.

-

Automation & Ball Transfer Ready

Seamlessly integrate the CI FiberMax into your automated workflow. It’s designed to work with the MARCH 400 automation system and add the Ball Transfer load station for easy moving of material.

-

Dual 24" Monitors

The ergonomic operator interface features dual 24" monitors with multiple pivot and rotation points. This allows for full 180-degree swing, giving operators complete freedom to position the display for optimal visibility and comfort.

-

All-Steel Frame

The foundation of the CI FiberMax is its robust, all-steel frame, featuring a 3/4" c-frame and a 1 1/2" end plate for maximum stability and longevity.

-

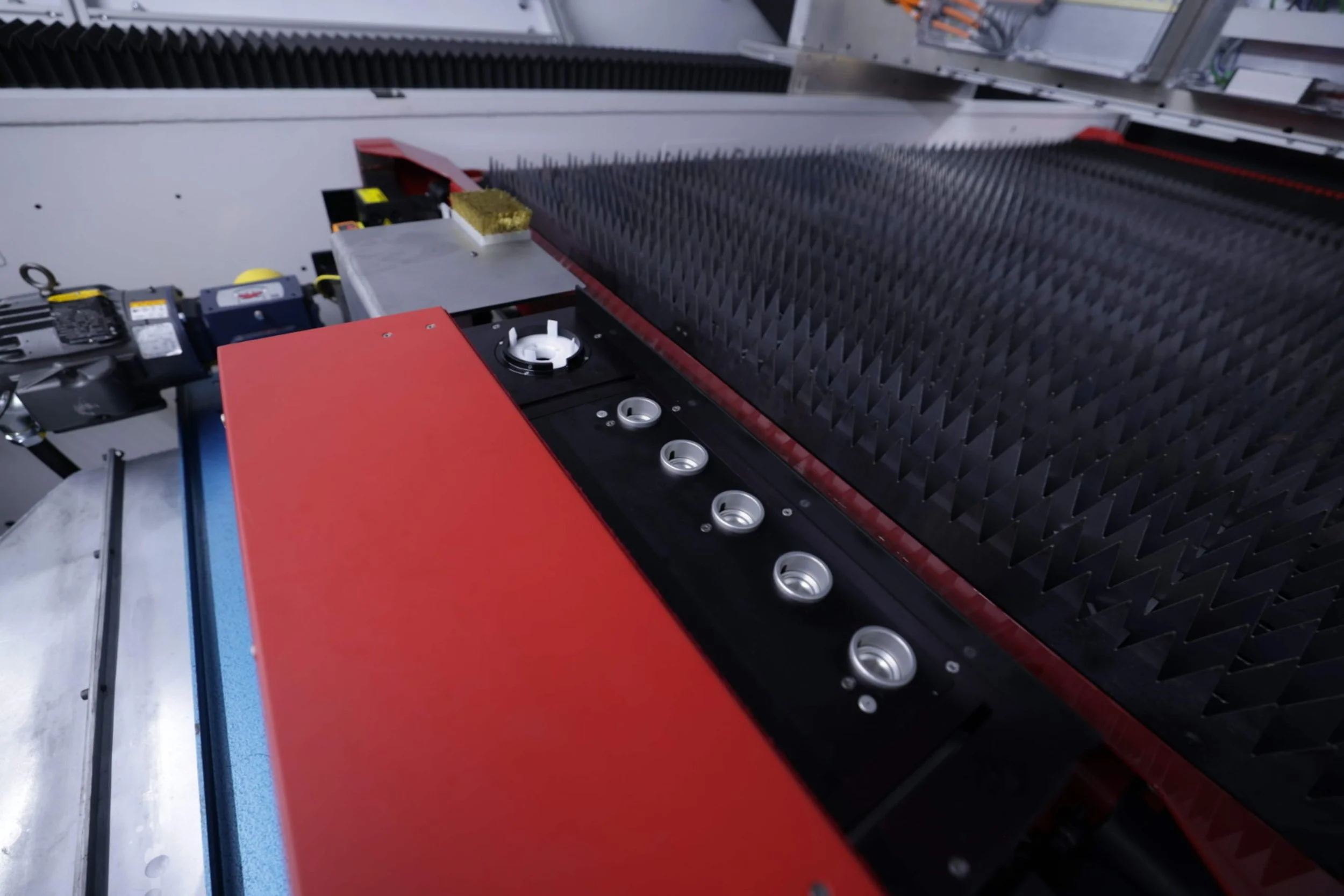

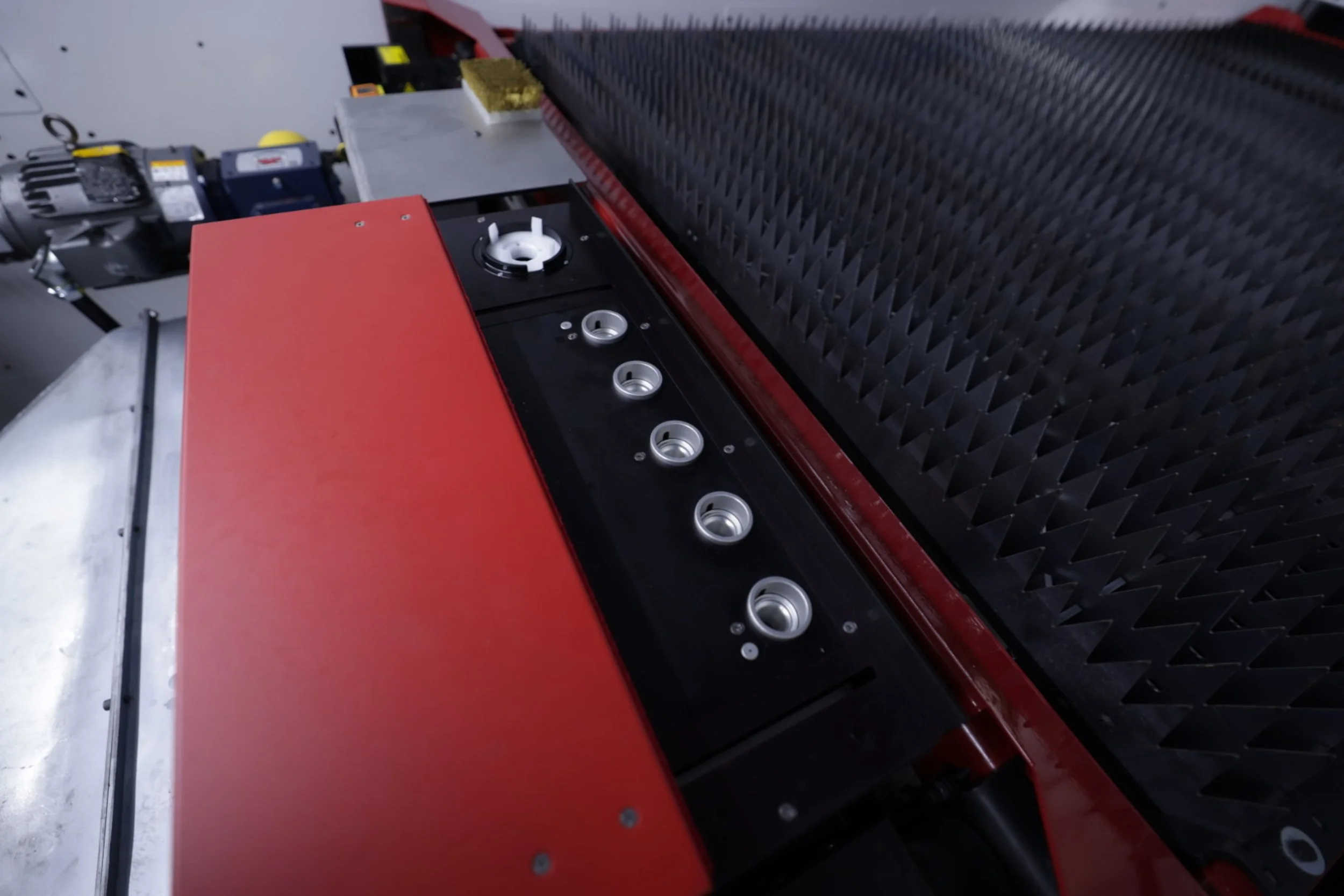

Embedded Storage Cabinet

Keep your workspace organized and efficient. The built-in storage cabinet is perfect for stowing commonly used items like nozzles, cleaning supplies, and related components.

-

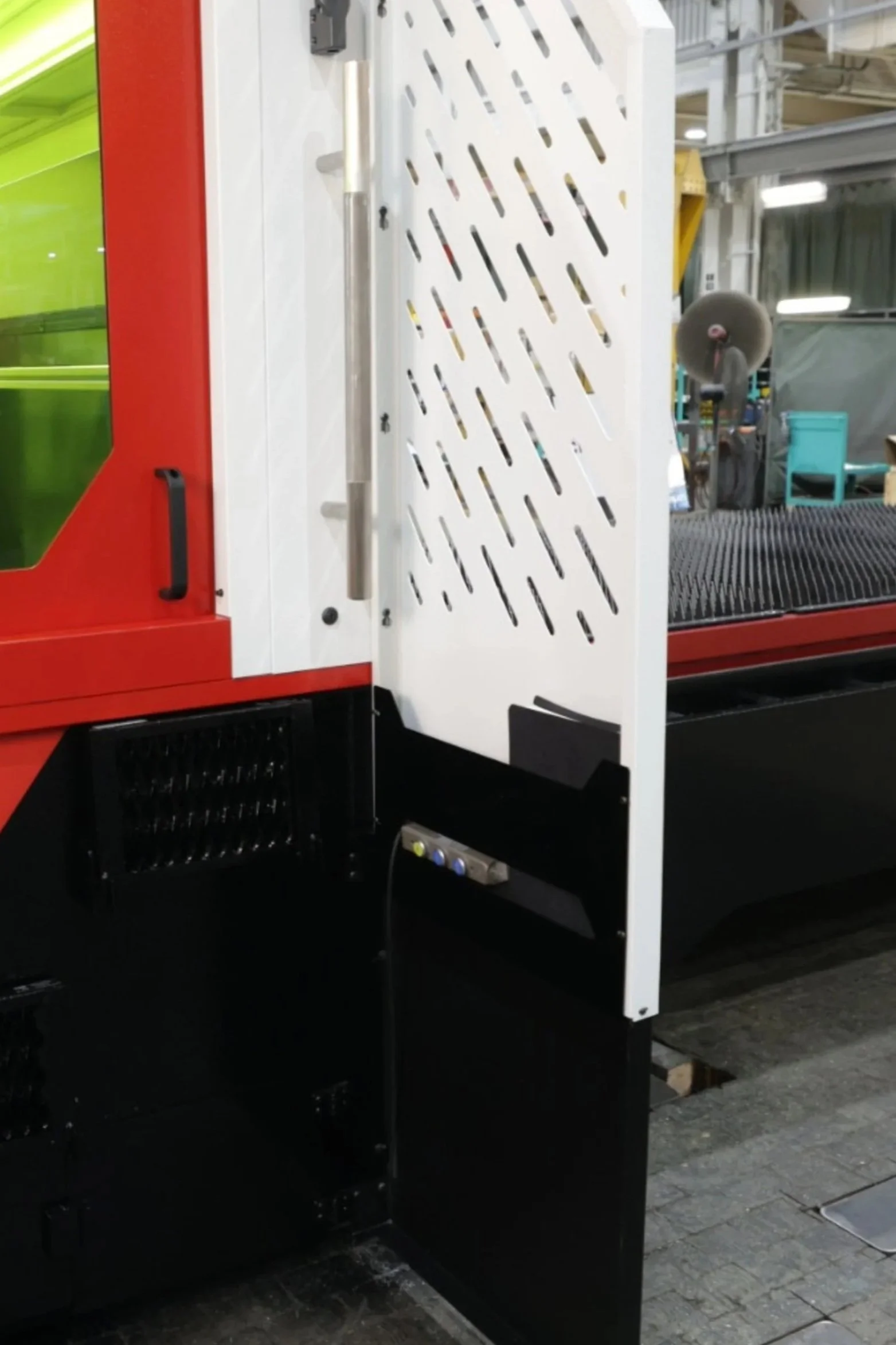

Safety Guard Pocket Storage

A built-in pocket conveniently stores manuals and documents. It also comes with magnets, allowing you to easily post user-defined documents for quick reference.

-

Redesigned Exhaust System

A new, highly efficient exhaust system features a smaller required collector (3000 CFM), a reduced exhaust ducting size (12”), a built-in spark arrest unit, and the ability to draw from both the left and right sides.

-

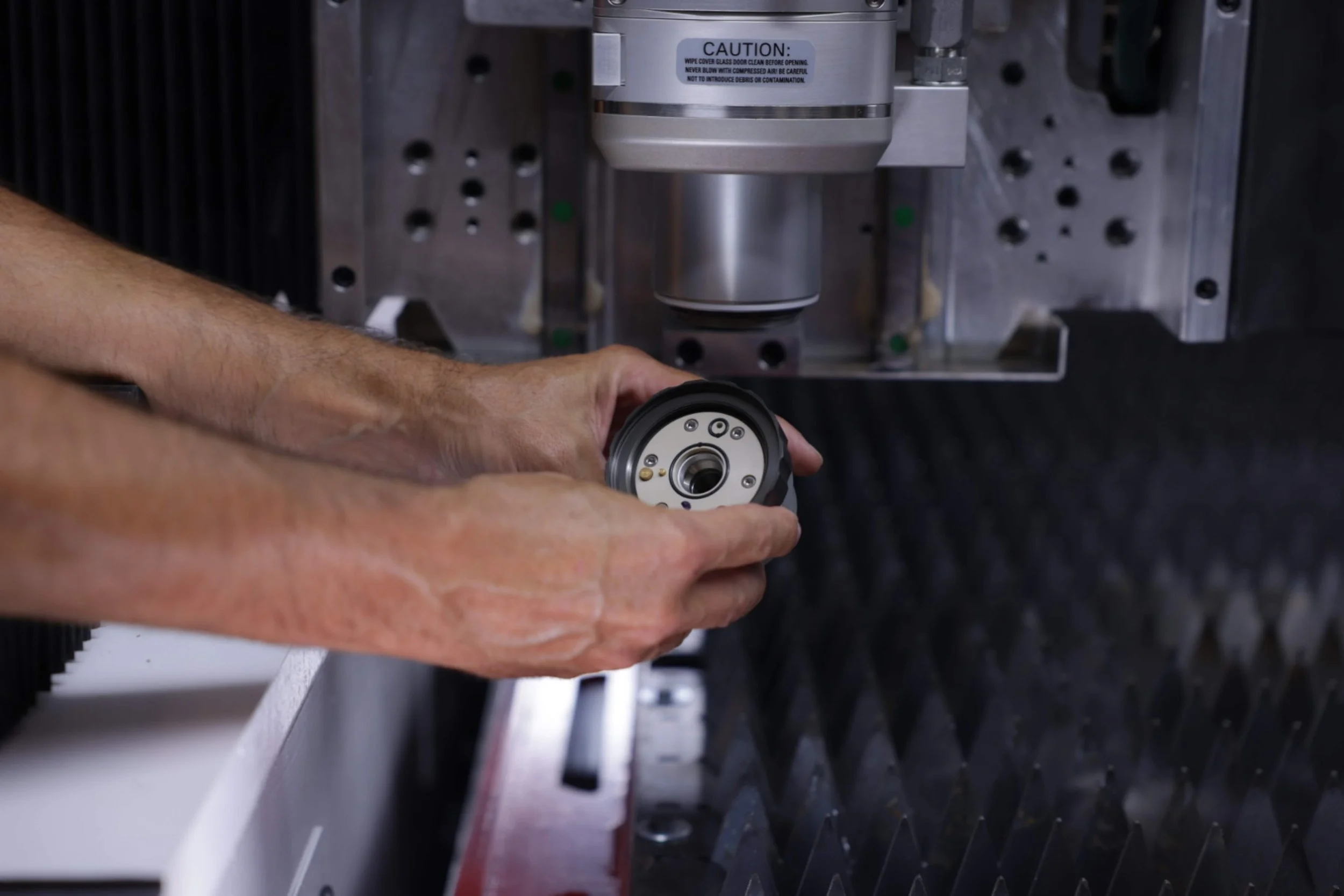

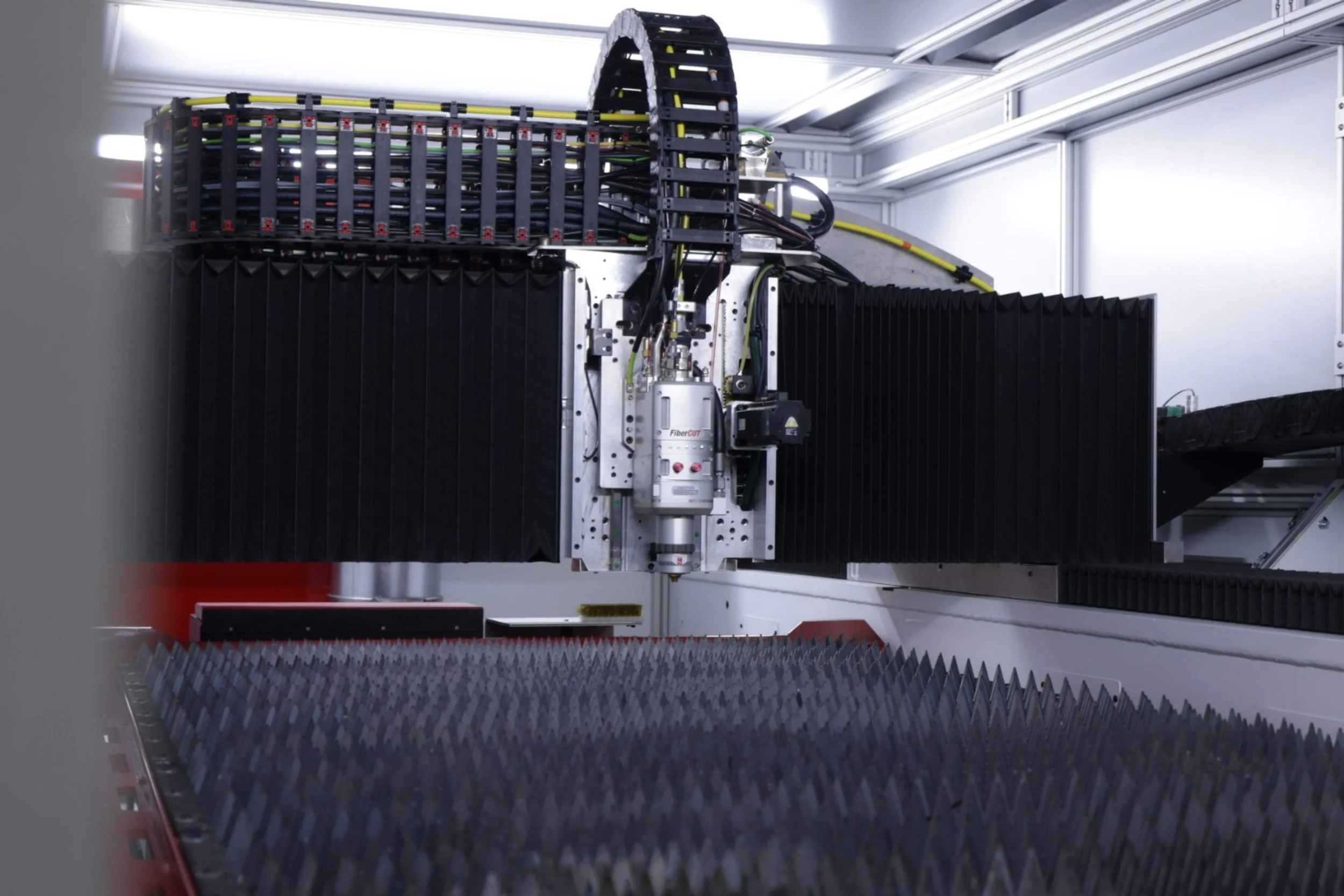

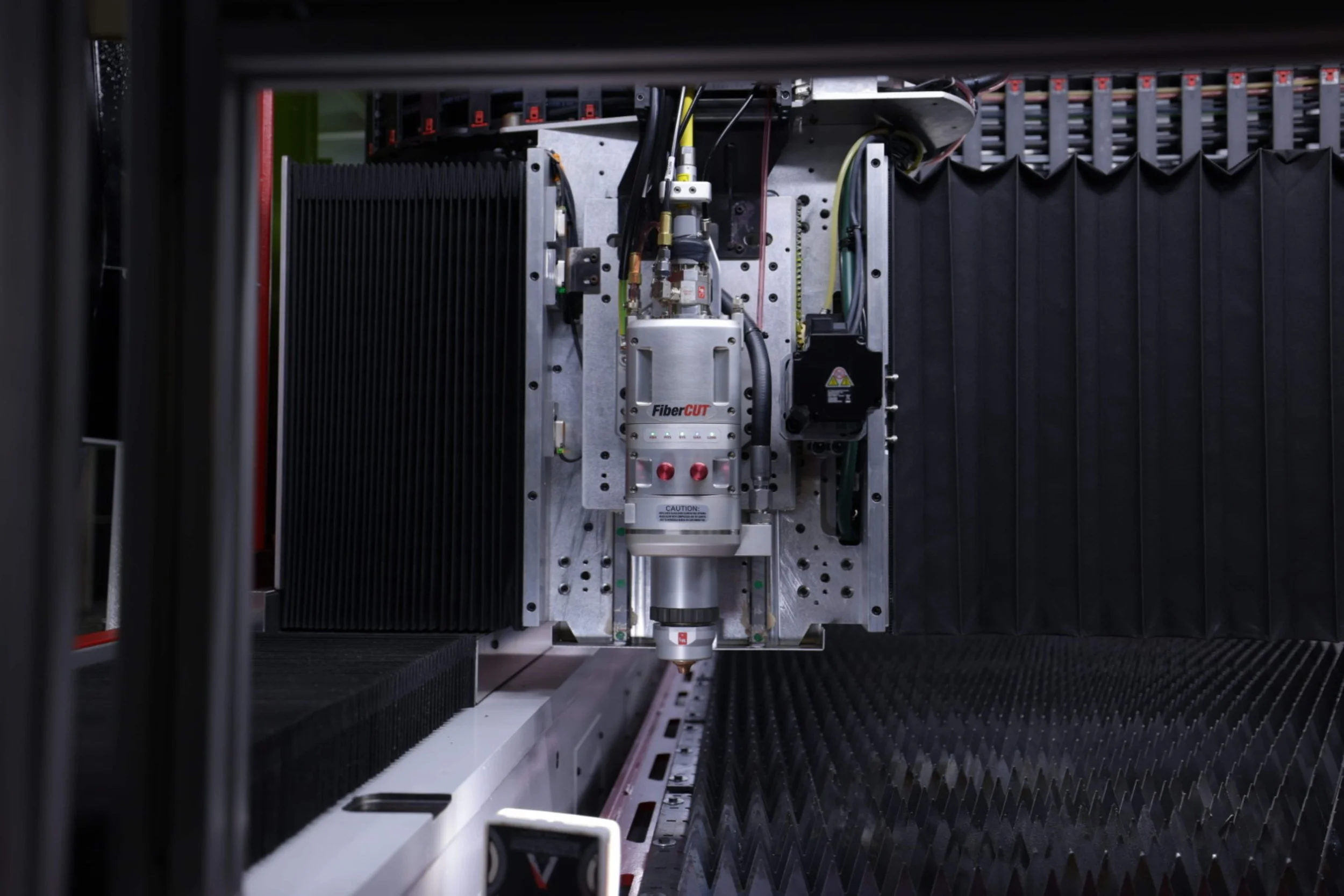

Fibercut 2DX head

Features the industry's largest diameter optics, a new autofocus system that is significantly faster than previous models, and a suite of internal sensors to monitor key conditions like humidity, pressure, and optic cleanliness.

-

Automatic Nozzle Changer

Automatically change and clean the cutting nozzle based on the nesting program and material requirements, eliminating the need for manual intervention and ensuring consistent cut quality.

-

Indicator Lights

High-visibility indicator lights provide an instant, easy-to-read status update on the machine from anywhere on the shop floor. These lights, which are visible from a distance around the upper part of the machine, give operators and supervisors a quick visual cue on the machine's operational status.

Monitor your laser’s health, anytime from any device with

We support you and the machine.

When you invest in a Cincinnati Incorporated machine, you're not just getting cutting-edge technology; you're gaining a partner. The CI FiberMax is backed by Cincinnati Incorporated's industry-leading preferred support and a dedicated team of factory-trained service technicians. From installation to ongoing maintenance and troubleshooting, our experts are committed to ensuring your machine performs at its peak, safeguarding your investment and minimizing any disruptions.

In-house and onsite training options available for operation and maintenance

1-year warranty on parts, labor, and more*

*Terms may apply, see company for details

Remote, phone, and onsite support at every budget level

Technical Specifications of the CI FiberMax

Available in the following table sizes: 3015 & 4020

Due to a continuous product development program, engineering data and dimensions are subject to change without notice. Foundation plans will be furnished for each installation.

| CI FIBERMAX |

3015 | 4020 |

|---|---|---|

| Working Area: X-Axis | 121" | 158" |

| Working Area: Y-Axis | 61" | 78" |

| Working Area: Z-Axis | 3.5" | 3.5" |

| Simultaneous Speed |

12,020 ipm

|

12,020 ipm |

| Positioning Accuracy | ±0.001" | ±0.001" |

| Repeatability | ±0.001" | ±0.001" |

| Work Piece Weight | 2,292 lbs | 3,500 lbs |