Introducing the Future of Fiber Laser Processing: The CI FiberMax

Greater Power, Productivity, and Smart Automation.

Applications and Engineering Team standing in front of the new CI FiberMax fiber laser system

HARRISON, OH, USA; SEPTEMBER 2, 2025 – Cincinnati Incorporated (CI), a U.S.-based builder of innovative metal fabrication technologies, announces the launch of its most advanced fiber laser cutting system to date, the CI FiberMax. With a reconstructed design, enhanced automation, and the highest cutting speeds the company has ever delivered, this next-generation fiber laser builds upon the legacy of its CI laser predecessor.

CI Business Unit Manager Matt Garbarino is quick to emphasize that the CI FiberMax is far more than a simple rebranding.

“For years, manufacturers across industry have trusted the CI laser cutters for their rugged dependability and unmatched throughput,” said Garbarino. “With the CI FiberMax, we’ve built upon that foundation to deliver greater power, faster cycle times, smarter automation, and a more intuitive operator experience. This is the machine fabricators have been asking for, and we’re proud to bring it to the shop floor.”

Key Features and Enhancements

Dual 24” Touchscreen Controls and built-in storage.

Proven Laser Cutting: The CI FiberMax builds on the reliability, table sizes, and high-power capabilities that have made CI lasers a benchmark in the industry, while upgrading core functionality for even greater efficiency.

High-Power Configurations: Available in 10 kW, 12 kW, and 15 kW power levels, the FiberMax processes thick plate with speed and precision, offering unmatched versatility.

Expanded Table Size: 3015 (3×1.5m) and 4020 (4×2m) table formats accommodate a wide range of material sizes, from everyday parts to oversized projects.

Fastest Pallet Exchange in its Class: A redesigned dual-pallet changer slashes pallet exchange to 11 seconds, accelerating production and further minimizing downtime.

Designed for the Operator: Dual-monitor control station with onboard programming, CIberDash™ integration, and a streamlined HMI for fast job setup and monitoring. A built-in storage shelf and document area is included, ensuring that important information is readily accessible.

Smart Automation: Automatic nozzle changer with quick-connect system, plus optional material handling modules, including Cincinnati’s MARCH 400, give users the flexibility to scale. Because the machine is automation-ready, MARCH can be leveraged from day one or seamlessly added down the road, making lights-out production easy to achieve.

Connectivity: The FiberMax is fully integrated with CI’s software suite, including Nesting Pro and Scheduler, enabling cloud-based monitoring, analytics, and job planning.

A New Era in Laser Cutting

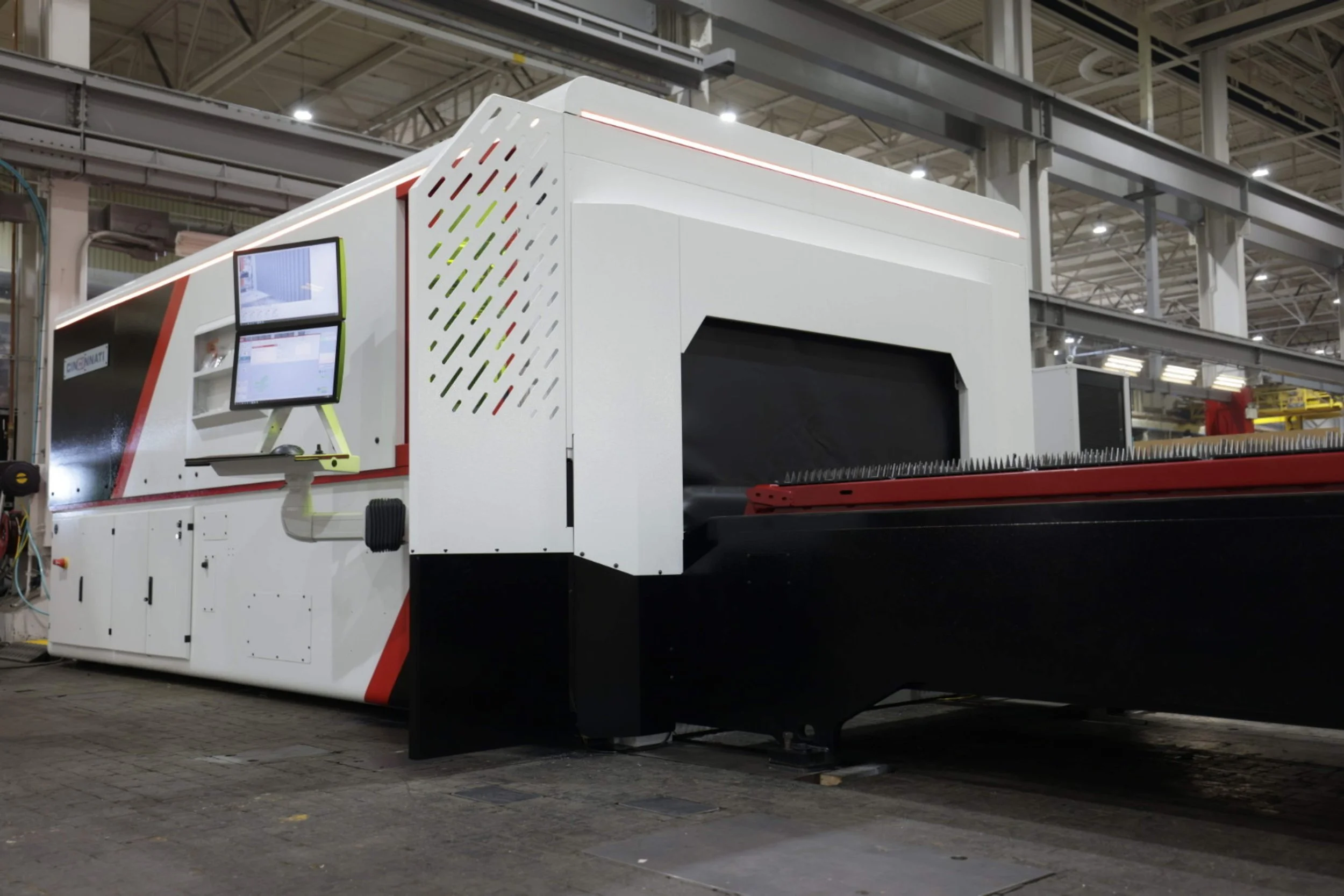

Exterior of the CI FiberMax

Designed for operators and built for owners, the CI FiberMax is ideal for shops that demand both flexibility and volume, combining intuitive operator design with automation-ready architecture. For existing CI laser users, the path to CI FiberMax is seamless, offering familiar performance with next-generation enhancements.

“This is the evolution of a proven platform,” Garbarino noted. “CI lasers have been an industry workhorse. Faster, smarter, and ready to grow with your businesses, the CI FiberMax is positioned to take laser cutting to an even higher level.”

Availability

The CI FiberMax will make its debut at FABTECH 2025 in Chicago. Show attendees can get a first-hand look at the machine by visiting Booth A4567. The CI FiberMax will be available for order beginning in Q1 2026 with customer demonstrations scheduled at CI’s Harrison, OH headquarters.

About CINCINNATI, Incorporated

CINCINNATI Incorporated is a U.S.-based, build-to-order machine tool manufacturer with over 125 years in the industry. Our engineering and manufacturing expertise makes us the ideal partner for companies building innovative products that demand extraordinary durability, stability, and industry-leading features. At our state-of-the-art, Ohio-based facility, we develop and build custom software, dependable laser cutting systems and automation equipment as well as metal fabrication equipment, including press brakes, shears, and PM presses. Our extensive knowledge puts us in a unique position to help drive efficiency in your manufacturing process no matter how simple or complex.

For more information visit www.e-ci.com.