Smart Approach

Think smart manufacturing is beyond reach? Think again

BY ROBERT FARRELL

One of the biggest mistakes a small to mid-size fabricator makes has nothing to do with equipment, personnel or partnerships. Rather, the error lies in dismissing automation as beyond what they need or can afford. Automation positions manufacturers for long-term success in an increasingly digital world. Reducing manual or repetitive efforts frees up skilled workers to focus on higher value tasks, minimizes errors, improves product quality and grows profitability through increased production capacity.

So, with these advantages and more, why do some fabricators shy away from automation?

Cincinnati Inc.’s Encompass software suite integrates a range of processes, including laser cutting and bending, to improve efficiency and precision on a shop floor.

Terms like smart manufacturing, artificial intelligence, machine learning, Big Data and Industry 4.0/5.0 can be overwhelming and even intimidating for those who see automated manufacturing as overly sophisticated and best-suited for large enterprises. Some believe that embracing smart manufacturing requires a hefty budget, a radical paradigm shift, sweeping changes and a technically savvy workforce capable of operating and maintaining these technologies.

Regardless of size, few manufacturers are in a position to overhaul the shop floor with the latest equipment and software. Fortunately, leveraging advanced manufacturing technology doesn’t have to be complex or expensive. The better option is to invest in modular software that can connect with existing equipment regardless of type or brand, interface with ERP/MRP systems, provide feedback to identify production bottlenecks and help ensure overall equipment effectiveness.

Front office automation

With its Encompass software suite, Cincinnati Inc. (CI) is putting smart manufacturing into the hands of manufacturers with a solution that is practical, highly scalable, flexible and surprisingly affordable. This comprehensive suite integrates a range of processes, including laser cutting, bending and additive manufacturing, to enhance efficiency and precision in metalworking.

As Colby Bowman, software product manager, explains, the product is all about software automation. What’s more, you can have it all with the investment of less than the cost of a press brake.

“With Encompass, we’re striving to reduce the workload in the front office,” he says. “We’re making it easy for programmers to get more done in less time and take on that little extra work needed to grow the business.

“In the past, programming stopped whenever a programmer took a break,” he adds. “Conversely, with our automated software, the process continues. We wanted this to be on the programming end for lasers and brakes, on the scheduling end and for data gathering. This helps to identify and eliminate production bottlenecks by replacing subjective guesswork with actual production data. What’s more, this is an economical way to elevate a shop.”

Seamless workflow

The comprehensive solution eliminates the need for disparate systems and multiple handoffs between the various stages of fabrication. This integrated approach leverages automation and enhances efficiency while reducing the likelihood of errors that can occur when transferring data between systems.

Manufacturers are empowered with a seamless workflow, from design to production, streamlining the entire fabrication lifecycle. The software’s user-friendly interface and intuitive controls make it accessible for operators of varying expertise levels.

Bryant Downey, software business unit leader at CI, says that with a focus on versatility, Encompass adapts to diverse manufacturing needs, ensuring flexibility and scalability.

“At the software’s core is its capability to unify various facets of metal fabrication, offering a holistic solution from design to production,” Downey says. “The suite incorporates state-of-the-art technologies, including primary and secondary operations such as laser cutting and bending. The result is a cohesive workflow that optimizes efficiency and precision.”

Recent enhancements to CIberDash

Custom reporting: Schedule and customize machine reports based on the shop’s needs. Schedule when, who and how frequently to receive raw machine data or pre-built reporting.

Custom dashboards: Save time by utilizing REST API to add CIberDash data to dashboards that have already been created or create new ones using products such as Excel or Grafana.

Custom time frames: Easily view up to six additional days of machine activity with expanded time frames.

CIberCast, when used with CIberDash, displays machine data on video monitors located throughout the manufacturing facility without the need for additional installations. In this way, supervisors and machine operators have a high-level look at schedules and machine and operator performance and know exactly where they stand against production targets.

InspXt is designed to facilitate rapid and precise first article inspection, quality reporting and reverse engineering. InspXt has a proven track record of enhancing production efficiency across various applications.

Design through analysis

Metal fabrication requirements can vary widely, but the different software facets that make up the complete suite make it an ideal solution to accommodate this diversity. Whether small-scale production with intricate designs or large-scale manufacturing of structural components, the product can scale to meet the specific needs of the operation. This scalability ensures that manufacturers have a flexible tool at their disposal, capable of handling a range of projects with ease.

CI’s Nesting Pro automates the process of nesting parts and helps users create enhanced nests with ease.

The software automates and streamlines complex processes. With its intuitive interface and advanced algorithms, the software efficiently handles repetitive tasks, saving time and reducing errors. From data management to workflow optimization, Encompass empowers fabricators to enhance productivity and focus on strategic initiatives, driving overall operational efficiency.

For design, the Unfolder module supports the import of standard 3-D solid models as well as most native formats. It’s good for developing a flat or simulating bending from a solid model. With Unfolder, users can accurately identify the correct flat blank and quickly import a 3-D geometry to the bend simulator.

Nesting Pro users can automate nesting and create enhanced nests by applying unique rules-based features. Programming productivity is further increased with batch conversion of flats or 3-D models automatically unfolded to the proper blank size. Users can automatically program and nest laser cutting with CI’s ERP interface.

For companies that employ lean manufacturing principles, the Scheduler module takes the guesswork out of balancing the laser workload. The program receives information directly from the system, automatically tracks material and machine availability, and schedules the job accordingly. Similarly, Scheduler can automatically account for secondary operations such as bending, grinding, painting and so on.

Precision bending is critical in metal fabrication, especially when dealing with complex shapes and structures. The BendSim Pro module incorporates advanced bending technology that allows operators to achieve the desired shapes with a high degree of accuracy. The software’s intuitive controls make it accessible to operators with varying levels of expertise, contributing to a more streamlined and efficient bending process.

Fully automated bending includes batch processing of multiple parts and automated tooling selection and tool station placement.

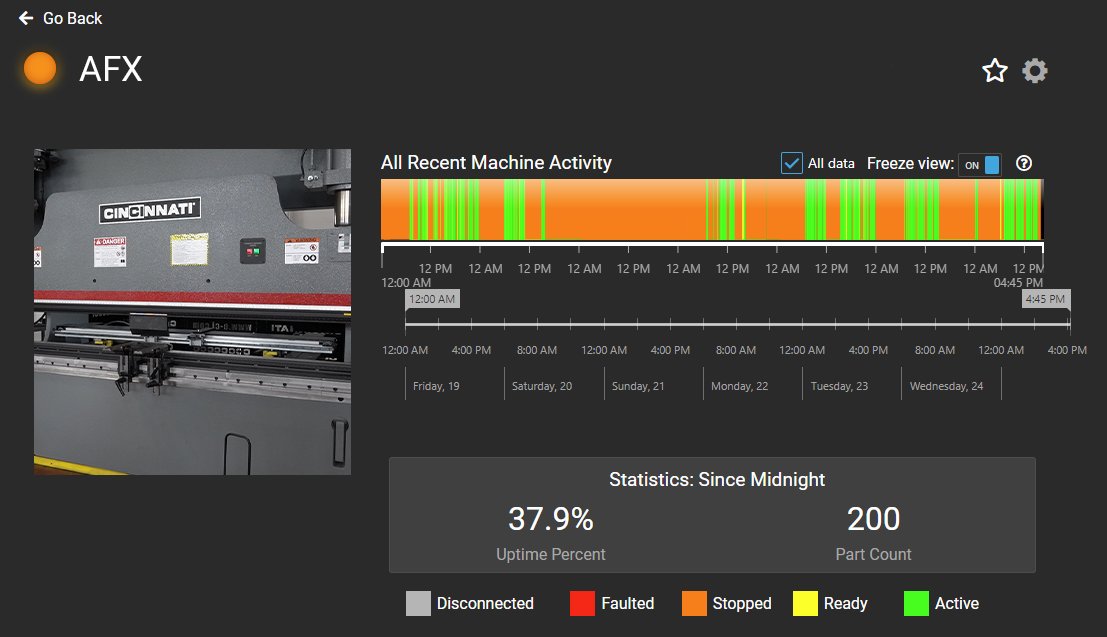

Finally, CIberDash provides real-time insight into machines, including production levels and downtime. The real-time dashboard or detailed log files provide information to analyze and optimize shop floor assets. Your machines are talking. Are you listening?

A history of innovation

For decades, smaller manufacturers watched from the sidelines as their larger counterparts reaped the benefits of smart manufacturing technologies. With heavy investments in resources, equipment and process changes, the technology and implementation were simply daunting and largely impractical for companies of limited size.

Advancements in technology have made automation increasingly practical and affordable. The availability of cost-effective robotic solutions, flexible automation tools and user-friendly programming interfaces has lowered entry barriers. Additionally, the scalability of automation allows businesses to start small and expand gradually, aligning with their specific needs and budget constraints.

Today, CI is putting powerful automation into the hands modest-size fabricators. By integrating metal fabrication into a cohesive, scalable and highly affordable package, the Encompass suite empowers smaller manufacturers to enhance their operations, improve product quality and stay competitive in an evolving market without the prohibitive costs associated with earlier automation technologies.