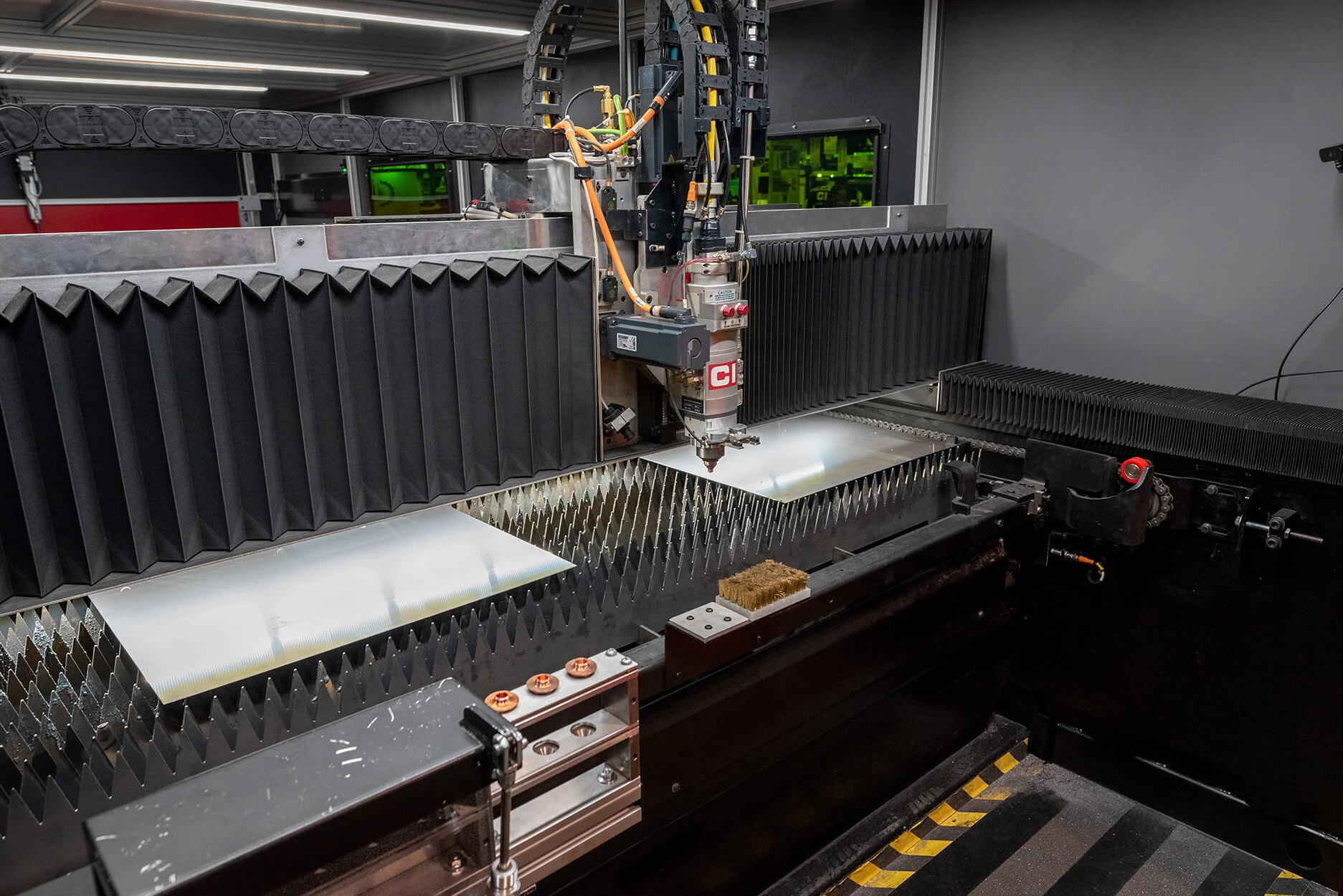

Introducing the CLX: Our All-New, From-the-Ground-Up Fiber Laser Cutter

For decades, CINCINNATI laser cutting machines were built upon the same frame. The architecture suited our CO2 systems well, but the rate at which fiber technology changes made it apparent that we needed a new platform. In February 2019, our manufacturing, service, engineering, sales, applications had their first meeting with a blank whiteboard. A mere eight months later, it’s official: The CLX is here.

Clean-Slate Collaboration

It was important that the CLX was built with an important question in mind: Does this improve functionality in a lights out environment? That’s where we started, and we brought our various teams together to make it happen.

Some of our best and most senior engineers worked on the project, but we also packed the team with some of our brightest young employees. They don't have any preconceived ideas from past CI machines, which freed the entire process up.

“That was certainly by design,” said Troy Wilson, CNC Table Products Product Manager. “It’s mostly just leaving the younger guys alone and letting them free think. They’re new to the company, they don’t have any reason to dwell on what was done in the past.

"I outlined the scope of the project and empowered our young engineers to do what it takes to get the job done," said Randy Adams, VP of Engineering. "They did just that. They took ownership, worked countless hours, assembled a team and met the goal to deliver a brand new laser platform on time."

“The collaborative process was noticeable in the meetings. Everyone’s ego was checked at the door with the goal of getting it right, not making sure your idea won,” Wilson said. “I was with a CI competitor for a long time, 17 years, and over there it was very much ‘get back in the box, do what we tell you.’ So to return to CI and see our team strive in the same direction for the best possible product was delightfully refreshing.”

The CLX also looks markedly different than its predecessors. One of our design engineers has worked in manufacturing for some time, and he jumped on the opportunity to work on the CLX design when we asked him. He’s a major reason the machine looks as good as it does, and we would not be at this point without him.

The Lighter and Smarter Laser Cutter

The CLX has the same beefy toughness as its predecessors (it’s a CINCINNATI, after all), but the frame weighs in at half the total weight. That lighter frame comes with a better brain, one that allows the machine to take care of itself, keep things moving and keep cutting material. Dual 24-inch touchscreen monitors allow operators to access machine controls while switching between four interior cameras with different aspect ratios.

“It was important to us to give operators a clear view of what the CLX is working on,” said Michael Loch, CNC Table Products Engineering Manager. “High resolution cameras give them that picture. Obviously, fiber lasers require full enclosure, which means your view is usually tinted with green or some other color. Not that case here. The high def cameras broadcast a clear, natural light image.”

Built for the Automation-Minded Metal Fabricator

We made a point of making sure our vendors have the same focus on automation as we do, and they’ve bellied up to the bar with us.

Our partners at nLight produce the CLX light source, and they worked with us to integrate failure analysis, health check functionality and cloud feedback that gives a heads up that the machine is getting sick. Predictive diagnoses on the CLX means you can get to the machine before it stops.

Beckhoff, experts in automation technology, helped us with IoT integration, remote communication with the machine and useful software help tools.

Laser Mechanisms’ software package allows us to track what’s going on with the head in real time, right on the screen for the operator to see if something was compromised in the cutting process.

The Dream Fiber Laser is Here

The phrase we’ve kicked around regarding the CLX is “math over mass.” We always build our machines tough and always will, so it wasn’t an outright goal to get our fiber lasers’ weight down. The goal was to fabricate it faster and let it become a universal tool. 50% less frame weight was just a byproduct when that goal was realized.

Does this improve functionality in a lights out environment? That was always the question, and every feature on the CLX proves it. If you’re looking to welcome a new fiber laser cutting system into your facility, you simply cannot do better than the CLX. You’re about to make your parts faster than you ever have before. Talk to us to learn more about the dream machine.