E.K. Machine Gains a Competitive Edge with CINCINNATI Laser Cutters and Automation

E.K. Machine Company started out 50 years ago as a small machine and fabrication shop. Since then, they have grown into a full-service supplier of quality steel components and assemblies to the agriculture, construction, food processing, oil/gas and transportation industries.

To diversify their product mix, the parent company launched E.K. Machine Power Products in 2008. This division makes everything from industrial-sized generator enclosures to fuel tanks, ISO containers and trailers. Today, the company ships products from their base in Fall River, Wisconsin to markets worldwide.

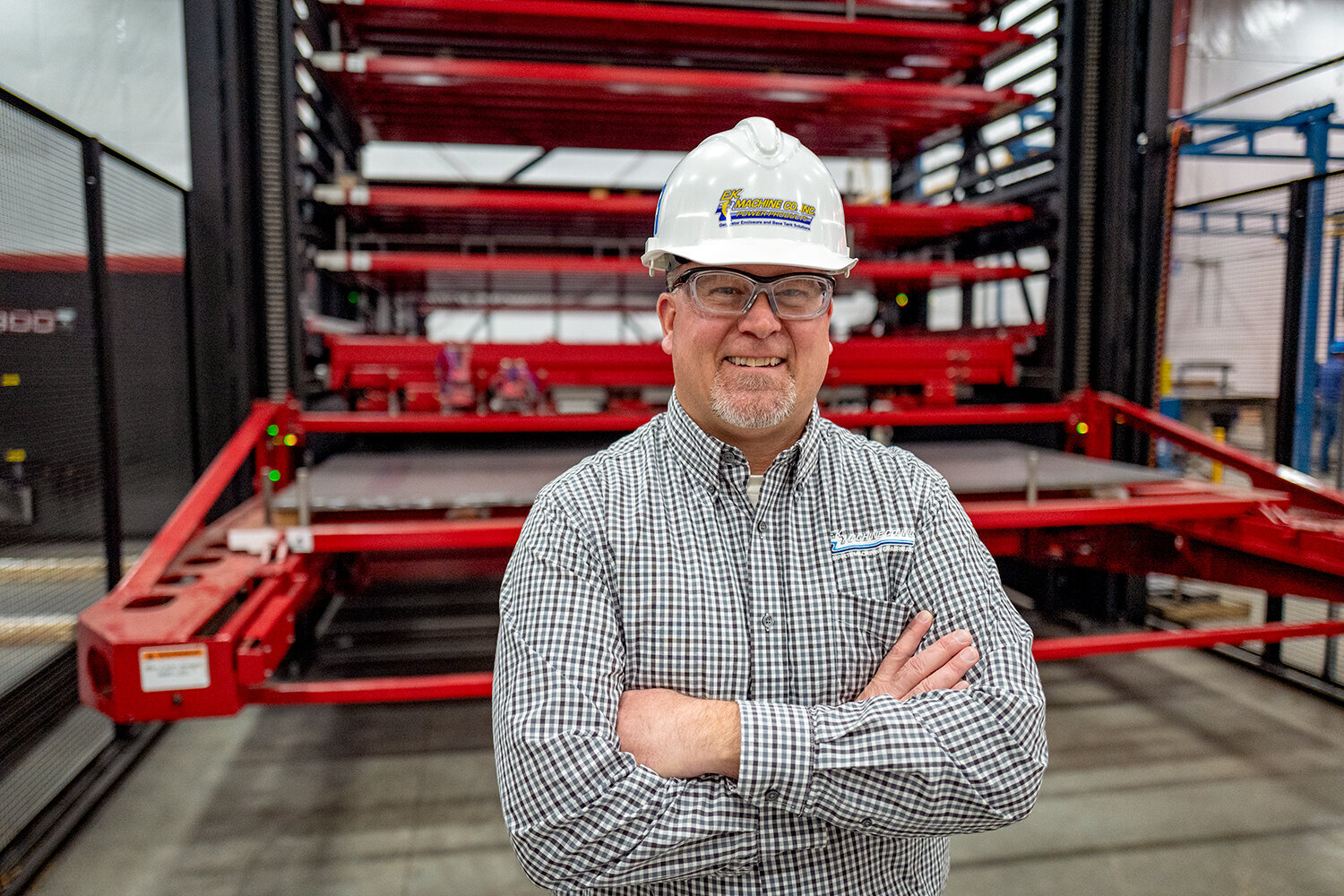

According to Steven Slack, E.K. Machine’s Vice President of Operations, it takes discipline to manage growth at a steady pace for such a long period of time. The company also depends on the finest technology for quality, speed and productivity. That’s where CINCINNATI enters the story.

Steven Slack, Vice President of Operations

Innovation, Longevity, Performance

E.K. Machine bought their first laser cutter, a CL-707, in 2000. Prior to that, the company used a laser punch or Strippit punch for some in-house jobs, and outsourced the rest. “The CL-707 was the first linear motor laser on the market,” Slack said. “It impressed us immediately when we saw it in operation. The feed rates were astronomical.”

“The CI laser increased productivity by cutting ½” plate with better geometries,” said Fabrication Supervisor Scott Baumgartner. “It also eliminated the need to buy a new punch for every hole size.”

E.K.’s original CL-707 is still in operation 19 years later, doing the same core and production work it began on Day One. A second CL-707 was purchased in 2002, and over the years the company added four CI press brakes. “Once we find something reliable, we stick with it,” Slack said. “In fact, we tried a Japanese laser cutter just for comparison, but soon got rid of it. The cutting speeds were slower, the quality wasn’t as good and maintenance was a constant problem.”

Technology is a Differentiator

E.K. Machine put a model CL-900 on the floor in 2013, mainly due to the fact that speeds are significantly higher than previous lasers. It was the company’s first fiber laser. Alongside that higher speed, it brought more reliability and lower maintenance costs. “It can do a clean cut in ½” steel at 60 IPM, and 85 IPM in 3/8” steel,”said Baumgartner. “It also has the same platform as the CL-707, which makes cross-training easy.”

The company recently purchased a new CL-900 + Multi Axis Rapid Cincinnati Handling (MARCH) automation system. MARCH feeds material to and from the laser as well as the CI press brake. Everything is done in one cell. “Loading material used to be a two-part manual process,” said Baumgartner. “Now the operator doesn’t even have to touch it.”

“Technology has always been one of our focal points,” Slack said. “With the current labor shortage, it’s critical to our ability to stay competitive.” Indeed, prior to adding the CL-900 + MARCH, making one sub-base fuel tank was taking 15 hours to cut, plus 5 hours to form. The same project now takes just ten hours to cut and form, for a reduction in process time of 50%. Further production gains are expected when E.K. Machine begins to run the CL-900 + MARCH in lights out operation mode.

If you’re thinking of moving up to first-class, American-made fabrication equipment that will help you grow your business for the future, contact us and see how we can help you like we helped E.K. Machine.