The Powerhouse

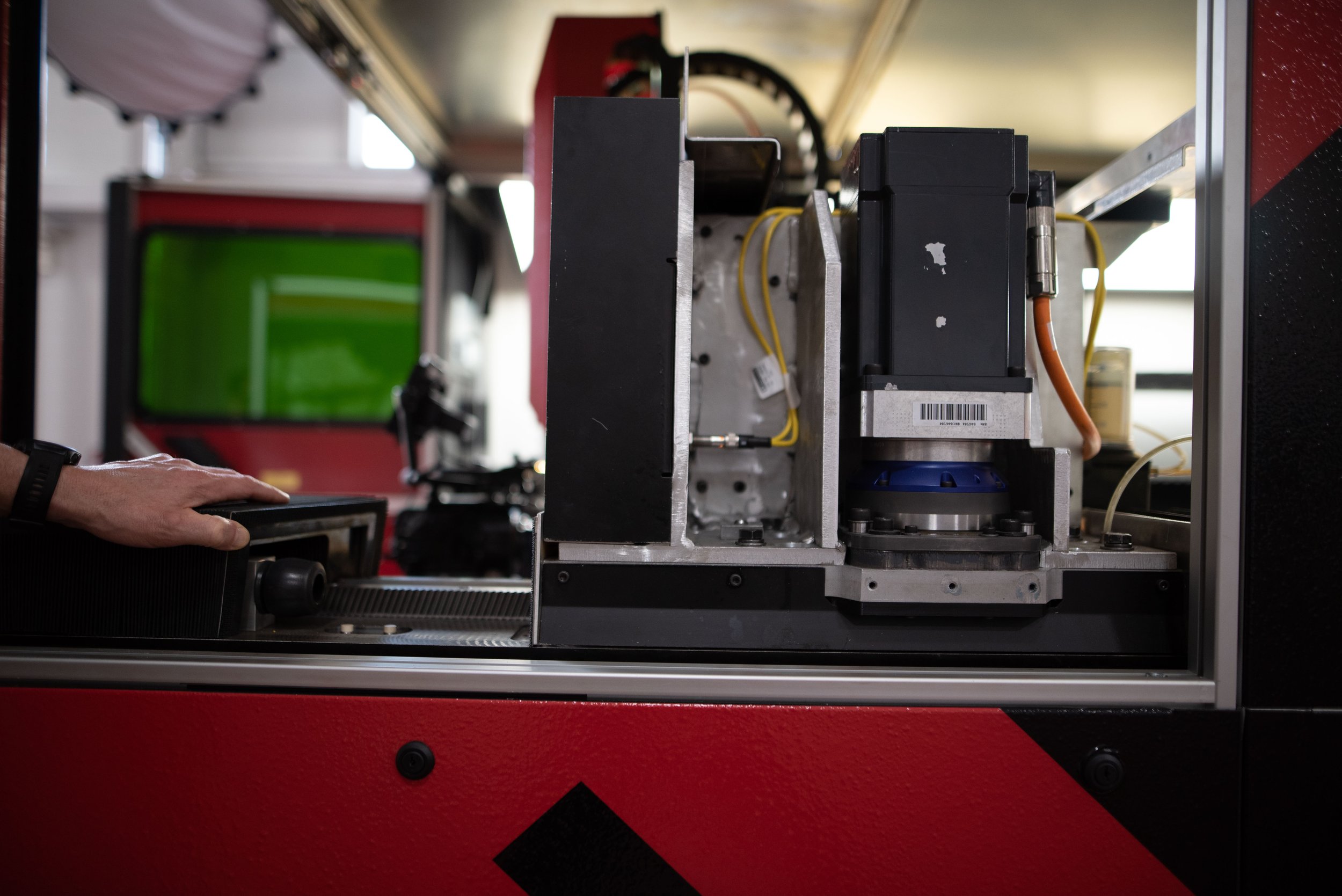

Fiber Laser

With the widest range of power from 5kw to 15kw means you can do more with your CLX fiber laser, faster and more efficiently than ever before.

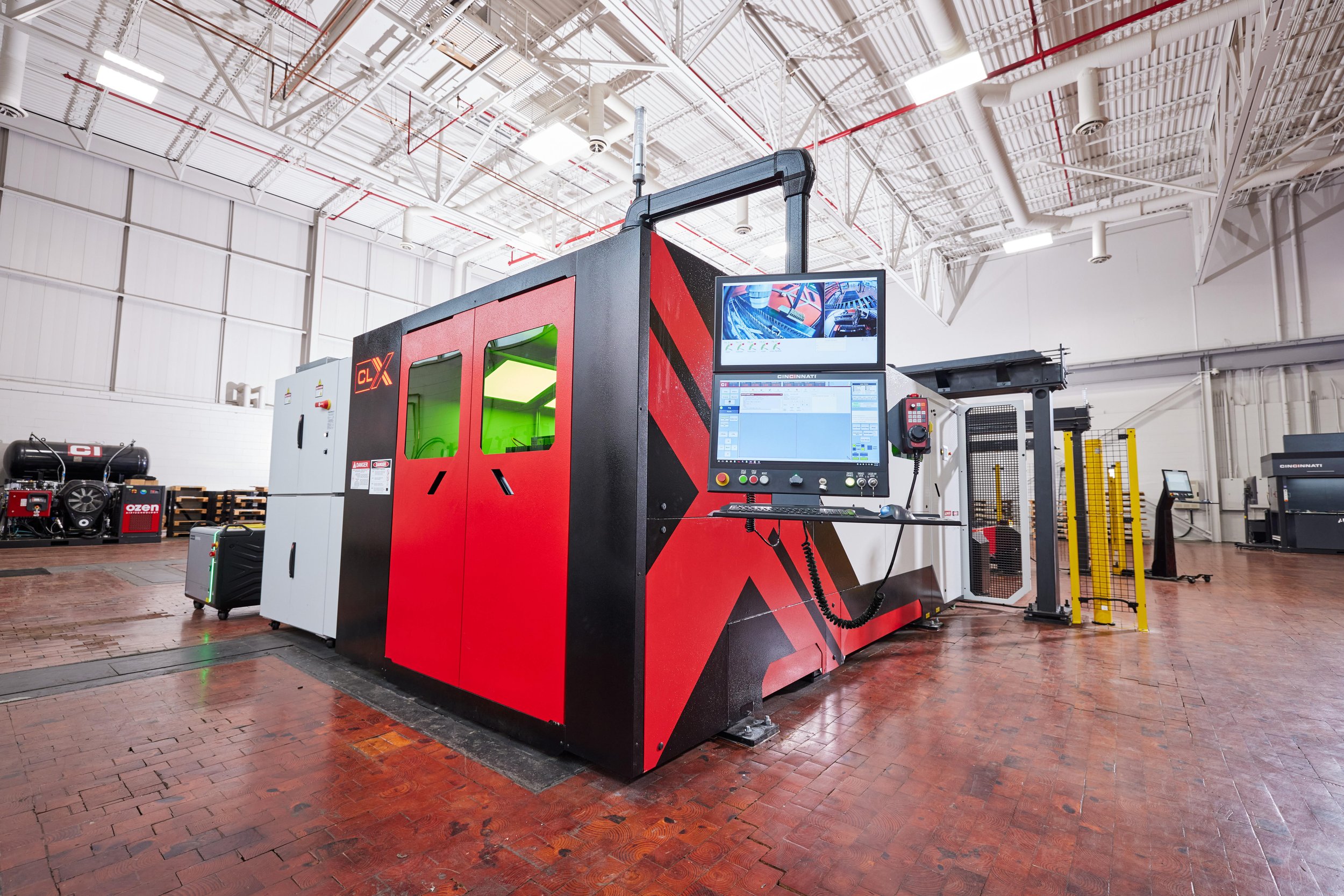

Where Modern meets POWER

We know you've got a lot on your plate. You're working around the clock to provide the best service possible to your customers, and we want to make sure that you can do it with ease.

That's why we've developed the CLX Fiber Laser.

The CLX is a fiber laser that has a wide range of power from 5kw to 15kw, meaning it can handle all kinds of material types and sizes. The hardware-based back-reflection protection allows the processing of even the most reflective metals with no interruptions or damage to the laser. It also has slats designed and modular for quick changeover and strength that maximize vertical strength. And debris removal is fast and easy!

Power for what you need

Place a CLX on your floor and watch how quickly it becomes your favorite.

Key Features

-

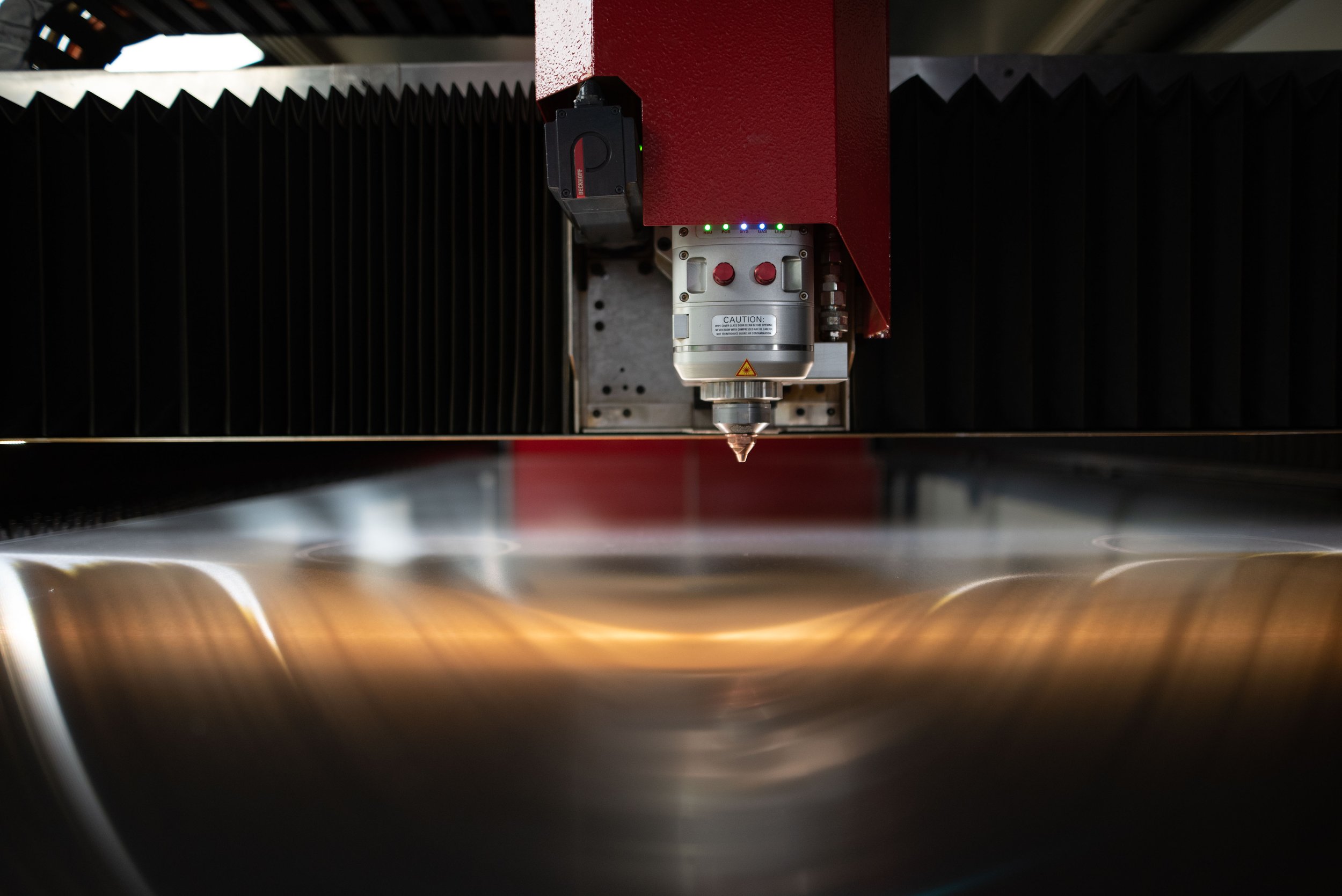

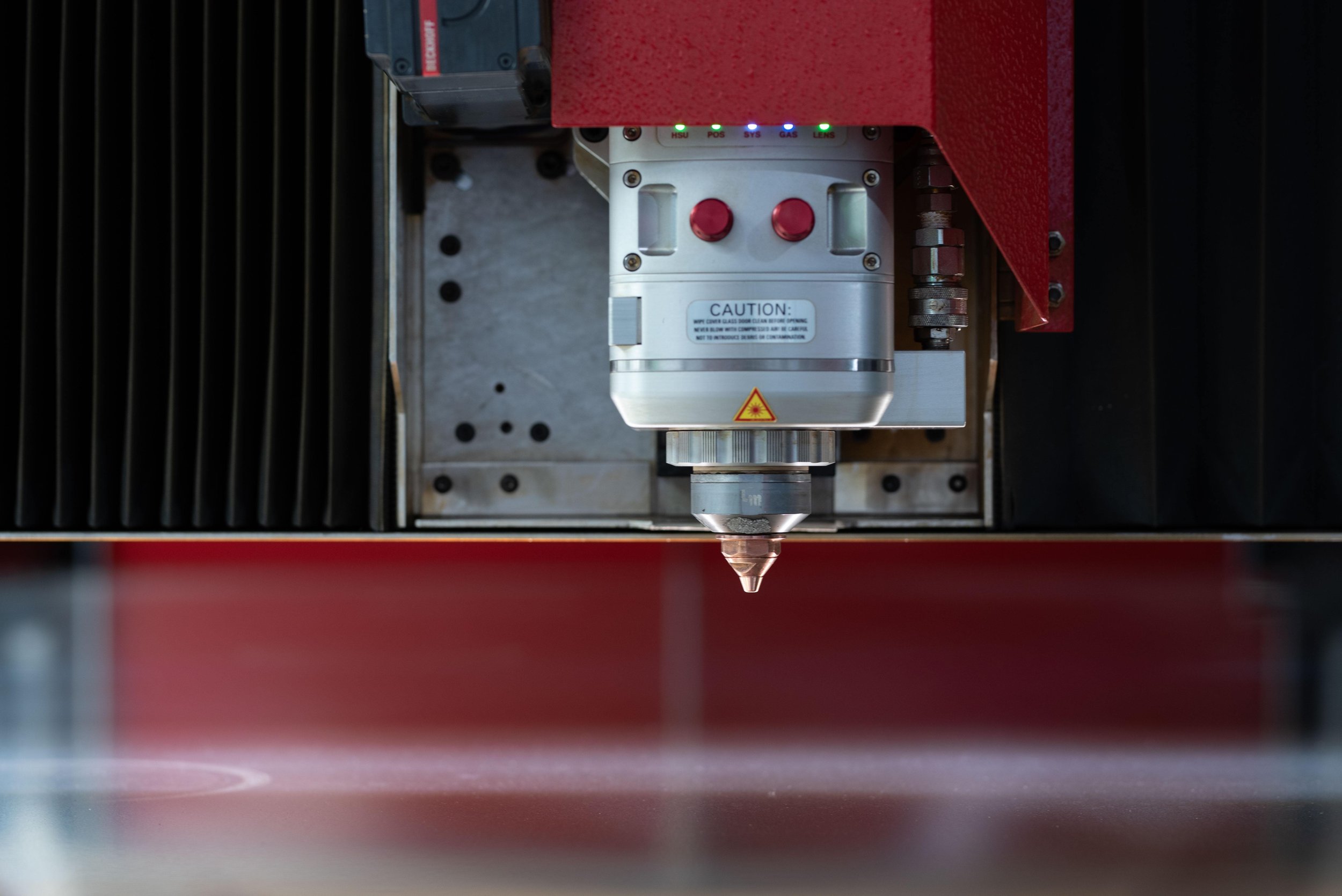

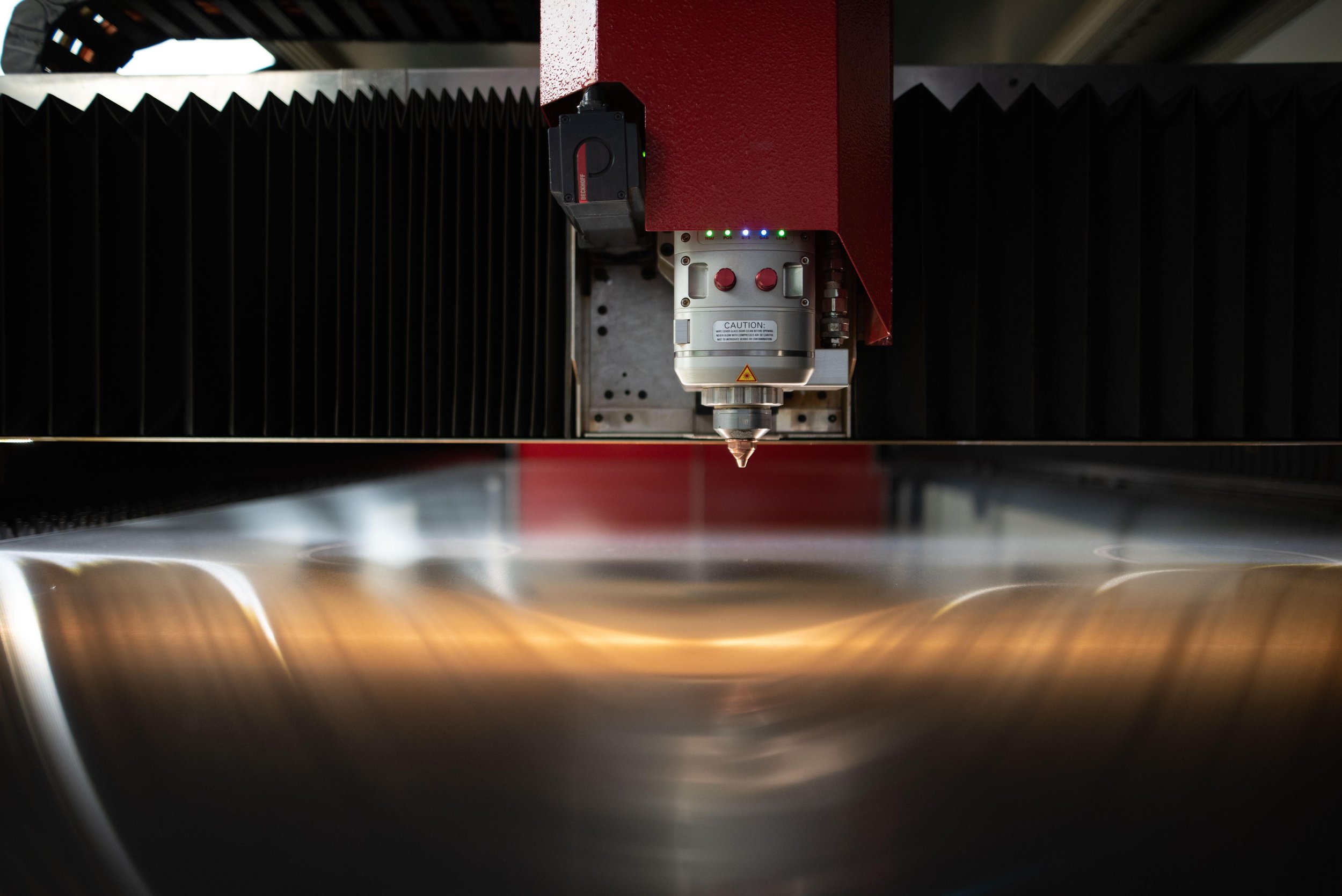

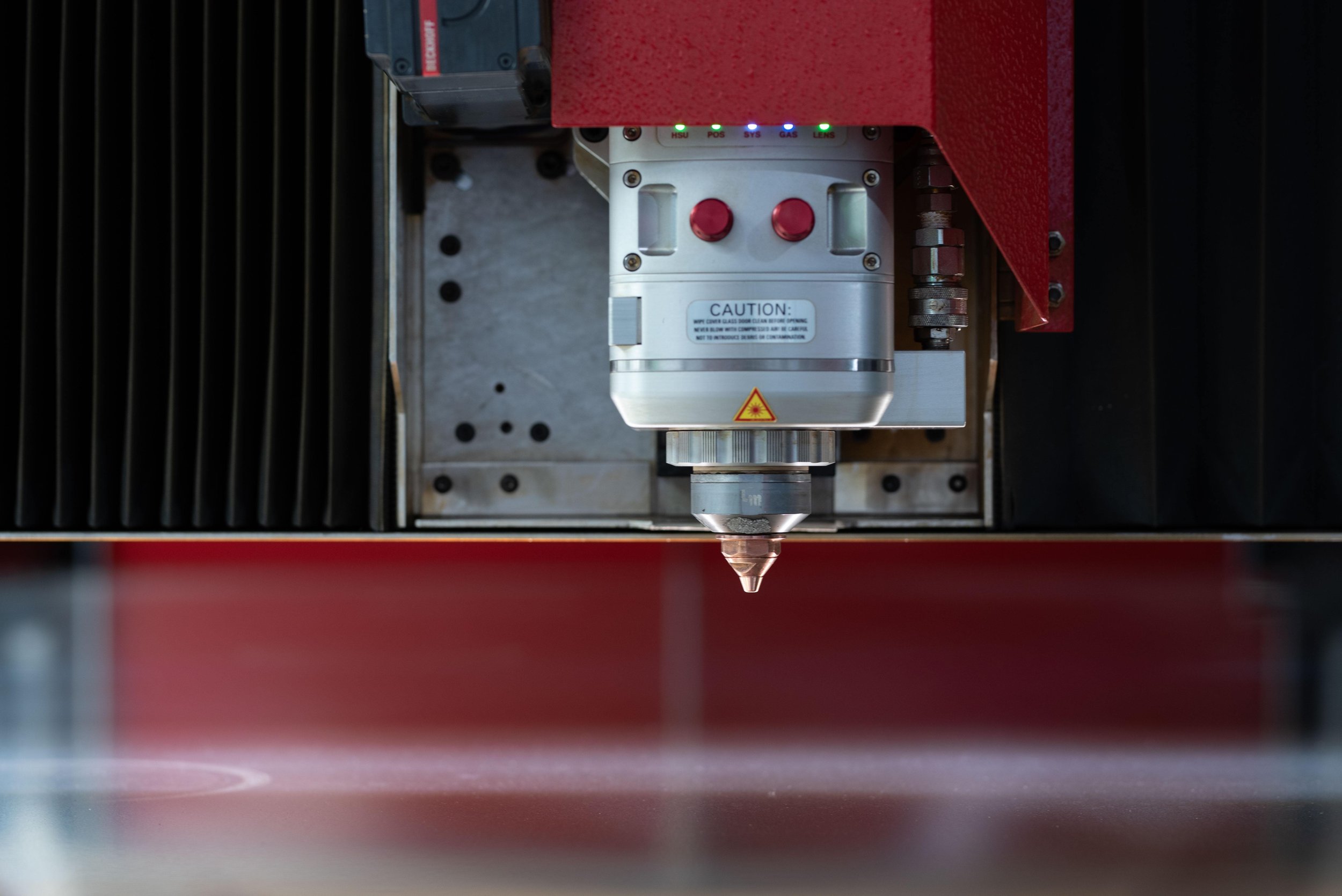

To the Point

The CLX’s FIberCut 2Dx Cutting head is designed for high power with high-power beam modes through the use of large-diameter optics.

-

Primed for Power

Programmable mode shaping fiber laser with power from 5kW to 15kW.

-

Easy Access

Users can enjoy the wide end table doors, which allow for effortless loading of remnants and convenient access to the 2Dx cutting head and Automatic Nozzle Changer (ANC). Additionally, the machine provides side access with folding steps, ensuring easy reach to the end of the sheet.

-

Automation Integration

If you want to make parts in a lights-out environment, know this: the CLX does too. Integrate the CLX seamlessly with the MARCH 400 Automation System.

-

Ergonomic Load Frame Design

Users can experience the innovative ergonomic design of the CLX load frame, featuring three pallet position heights for easy part removal. The slim frame design minimizes back strain, prioritizing user comfort and safety. With a conveniently located pallet control panel, operators can efficiently manage operations with ease.

-

Slats Built for Power

Stainless steel slats are designed and modular for quick changeover and to maximize vertical strength.

-

Simple Scrap Collecltion

Strategically located to maximize distance from the fiber laser beam. Wheels under the trays provide convenient access and its unique design makes clean-up fast and easy.

-

Touchscreen Dual Controls

Control every aspect of your machine with the high resolution, 22” dual touch screen monitors with integrated nesting and access to 3 internal webcams to view your progress in action.

-

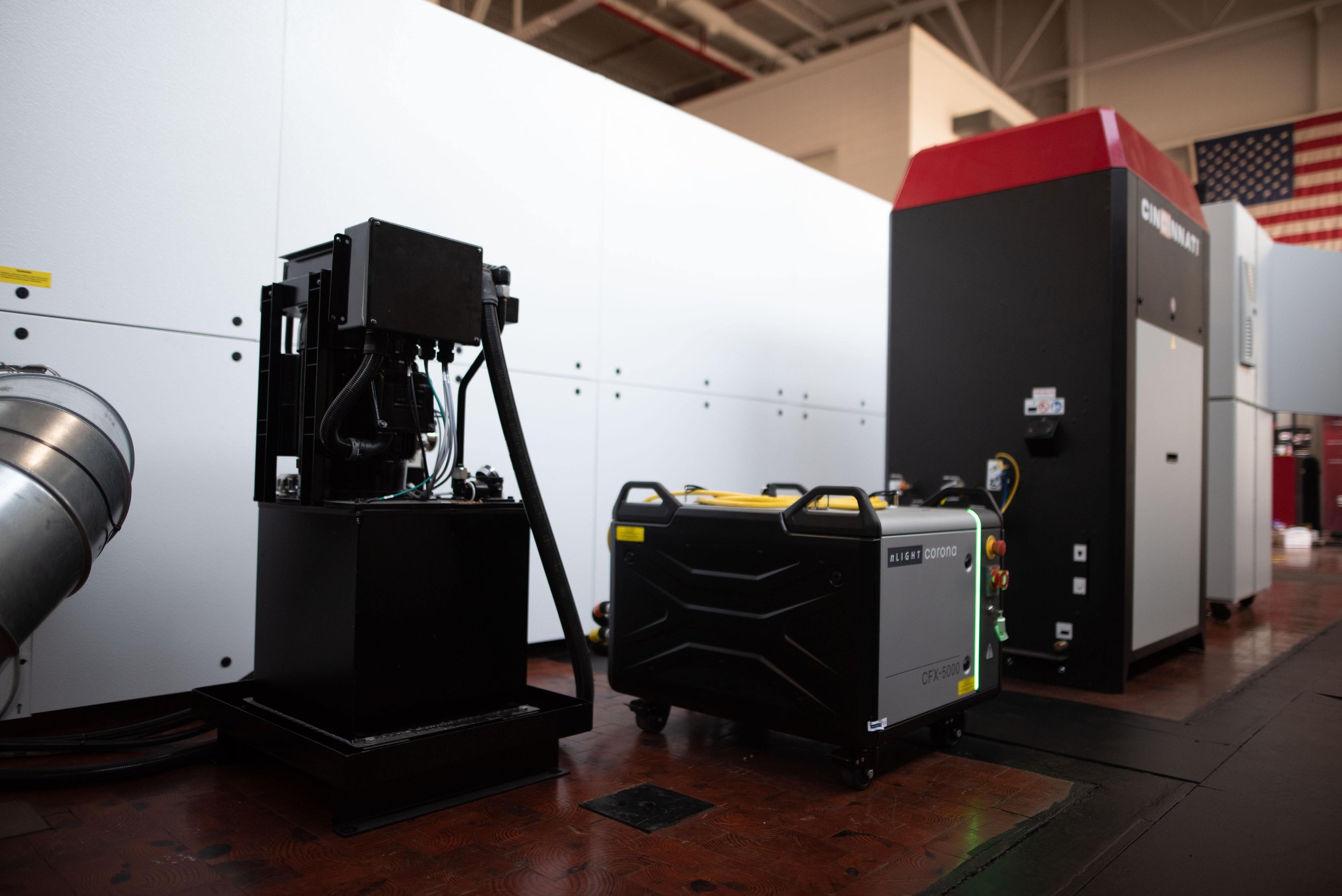

Chiller to take the Heat

intelligent Laser Colling System (iLCS) maintains precise laser wavelength and higher output efficiency, achieves desired beam quality and reduces thermal stress on the laser unit.

-

Time Saving Drives

With the CLX’s high-speed helical drives, you will get exceptionally faster cutting speeds and shorter processing times.

-

Nozzle for every Occasion

With the CLX’s advanced Automatic Nozzle Changer (ANC) you can automatically change the nozzle based on material type and thickness as defined in your program setup without lifting a finger.

-

Loss of Cut Detection

Equipped with sensors inside the 2Dx cutting head, the CLX machine ensures precise and accurate cuts. The LOC detection technology enhances the cutting process, providing users with improved and superior results.

Specifications

Available in the following table sizes: 3.0m x 1.5m, 2m x 4m

Due to a continuous product development program, engineering data and dimensions are subject to change without notice. Certified foundation plans will be furnished for each installation.

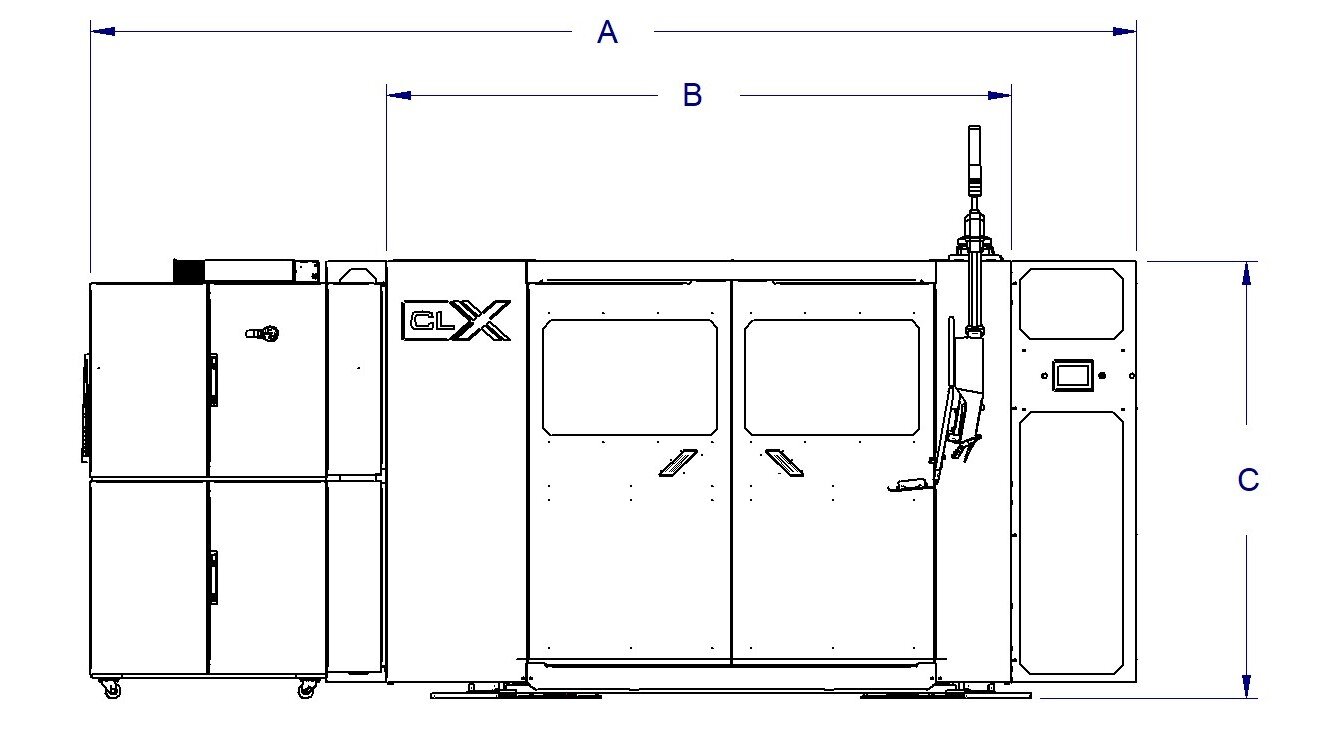

CLX Front View

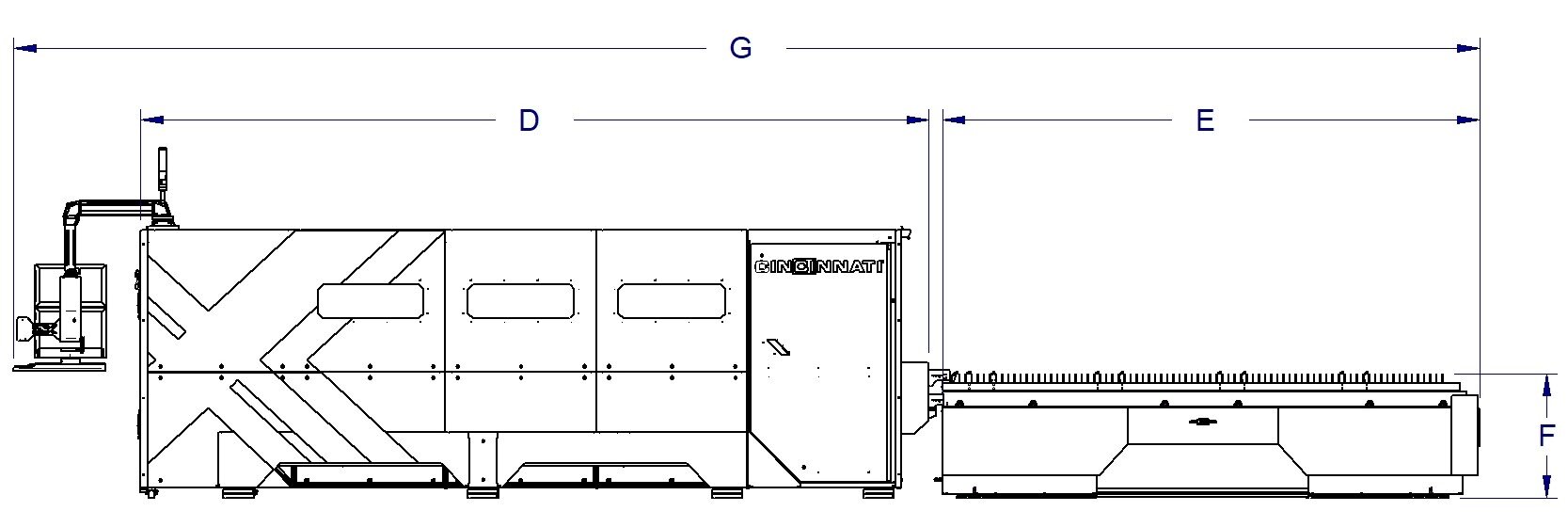

CLX Side View

| Pallet Dimensions | 3.0m x 1.5m | 2m x 4m |

|---|---|---|

| A | 190.3" (4,834 mm) | 209.2" (5,314 mm) |

| B | 106.2" (2,697 mm) | 124.9" (3,172 mm) |

| C | 87.5" (2,223 mm) | 87.5" (2,223 mm) |

| D | 220.3" (5,596 mm) | 257.8" (6,548 mm) |

| E | 137.7" (3,498 mm) | 175.7" (4,463 mm) |

| F | 40.5" (1,029 mm) | 40.5" (1,029 mm) |

| G | 404.2" (10,267 mm) | 479.5" (12,179 mm) |

| Weight | 24,500 lbs (11,113 kg) | 29,500 lbs (13,381 kg) |

Available Software

-

Nesting Pro

Amplify your ability to nest your laser parts with software automation, and create optimized machine code to make your Cincinnati laser (and most other lasers) operate at top performance

-

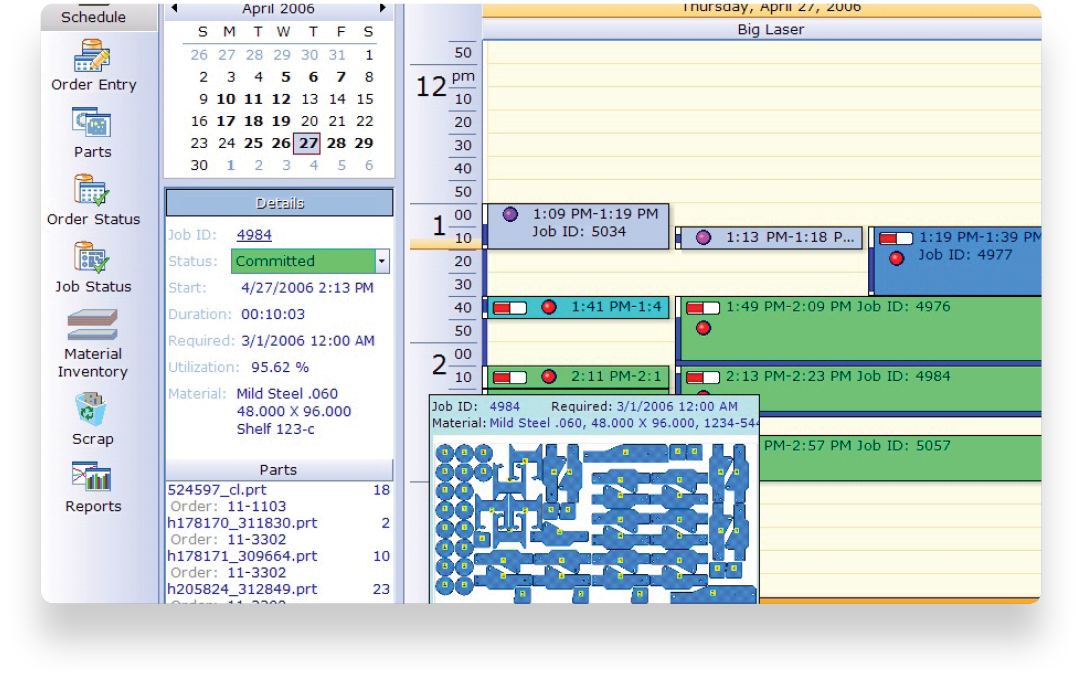

Scheduler

Take the stress out of scheduling by automatically scheduling multiple jobs across multiple shifts and multiple CI lasers.

-

CIberDash

Get real-time insight into all of your CI machines anytime from any device.

Featured Add-On

Experience a clearer way to cut with

ASSIST Gas cutting

Assist Gas Cutting is a self-contained, palletized source for providing enough air assist gas for cutting parameters that require up to 275psi at a nozzle of up to 0.100" diameter. The palletized system also provides 90 psi air for the purge and nozzle cooling requirement.