The Cleaner and More

Economical way to cut

For over 15 years, CINCINNATI has offered a process where clean, filtered, air is used as a substitute for the expensive nitrogen assist gas for both CO2 and Fiber lasers.

The basis of our Assist Gas Cutting technology is the fact that air is approximately 80% nitrogen. The remaining components of air consist mostly of oxygen and some trace gases. The goal with Air Assist is to maximize the beneficial effects of the 80% nitrogen component.

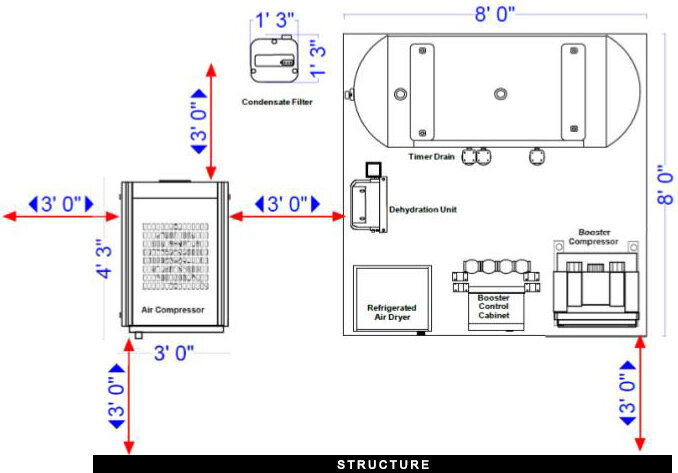

Assist Gas Cutting is a self-contained, palletized source for providing enough air assist gas for cutting parameters that require up to 275psi at a nozzle of up to 0.100" diameter. The palletized system also provides 90 psi air for the purge and nozzle cooling requirement.

Ideal for 1 laser

D90-V50M (50 scfm)

| Features | Voltage | Full Load Amps | Discounted Fuse (amps) | Wire Size |

|---|---|---|---|---|

| Air Compressor | 460 / 3 /60 | 29.7 | 40 | (3) * 6 AWG + (1) * AWG |

| Transformer | 460 / 3 / 60 | 42.4 | 50 | (4) * 6 AWG |

| *Booster Control Cabinet | 460 / 3 /60 | 27 | 40 | (4) * 8 AWG |

| *Refrigerated Air Dryer | 115 / 1 / 60 | 9.89 (12.80 MCA) | 20 | 12 AWG |

| *Desiccant Air Dryer | 115 / 1 / 60 | 1.3 | 15 | 14 AWG |

| *Timer Drain | 115 / 1 / 60 | 1.3 | 15 | 14 AWG |

* Supplied by transformer

Ideal for 1 laser and air support for automation

D90-V75M (75 scfm)

| Features | Voltage | Full Load Amps | Discounted Fuse (amps) | Wire Size |

|---|---|---|---|---|

| Air Compressor | 460 / 3 /60 | 35.9 | 50 | (3) * 6 AWG + (1) * AWG |

| Transformer | 460 / 3 / 60 | 36.78 | 50 | (4) * 6 AWG |

| *Booster Control Cabinet | 460 / 3 /60 | 27 | 40 | (4) * 8 AWG |

| *Refrigerated Air Dryer | 115 / 1 / 60 | 12.85 (17.18 MCA) |

20 | 12 AWG |

| *Desiccant Air Dryer | 115 / 1 / 60 | 1.3 | 15 | 14 AWG |

| *Timer Drain | 115 / 1 / 60 | 1.3 | 15 | 14 AWG |

* Supplied by transformer

Ideal for 2 lasers

D90-V100M (100 scfm)

| Features | Voltage | Full Load Amps | Discounted Fuse (amps) | Wire Size |

|---|---|---|---|---|

| Air Compressor | 460 / 3 /60 | 44.2 | 60 | (3) * 6 AWG + (1) * AWG |

| Transformer | 460 / 3 / 60 | 38.45 | 50 | (4) * 8 AWG |

| *Booster Control Cabinet | 460 / 3 /60 | 27 | 40 | (4) * 8 AWG |

| *Refrigerated Air Dryer | 230/ 1 / 60 | 6.7 (8.85 MCA) | 10 | 14 AWG |

| *Desiccant Air Dryer | 115 / 1 / 60 | 1.3 | 15 | 14 AWG |

| *Timer Drain | 115 / 1 / 60 | 1.3 | 15 | 14 AWG |

* Supplied by transformer

Specifications

CINCINNATI follows the policy of continuous advancement in product development. For this reason, specifications and dimensions are for reference only and can change without notice. Foundation plans are furnished with each new machine installation.

Requirements For Assist Gas Cutting

Supply requirements are different from the nozzle requirement because of losses at the filter and gas delivery piping. As with any laser process, confirm your application requirement with a CINCINNATI application specialist before making any purchases to support this process.

| System Specifications | D90-V50M | D90-V75M | D90-V100M |

|---|---|---|---|

| Flow Rate (scfm) | 50 | 75 | 100 |

| Air Dew Point | 128 ppm/v H2O | 128 ppm/v H2O | 128 ppm/v H2O |

| Delivery Pressure (psig) | 500 | 500 | 500 |

| Air Compressor | 18 kW (25 HP) | 22 kW (30 HP) | 30 kW (40 HP) |

| Booster Compressor | 15 kW (20 HP) | 15 kW (20 HP) | 15 kW (20 HP) |

key Features

Stainless steel parts cut with air exhibit a bright edge with traces of straw color. Although some cosmetic parts cannot show any blemish whatsoever and would not be candidates for this process, most stainless parts used in assemblies can be cut with air assist.

Similarly, most mild steel parts cut with air assist gas can be taken immediately to painting without the usual secondary operation of oxide removal. All CINCINNATI lasers come standard with parameters for air assist cutting for mild steel.