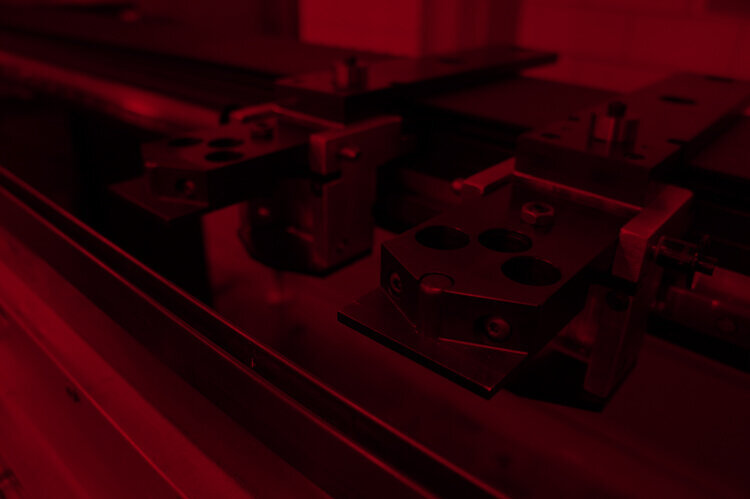

5-Axis Backgage Upgrade

Reduce setup times and get complex part gaging on your existing Cincinnati press brake with a 5-axis backgage retrofit.

Features

Independent Control of 5 Axes

The low profile backgage provides independent control of two front-to-back (X1, X2) axes, two left-to-right (Z1, Z2) axes and one up-down (R) axis.

Enhanced Productivity

The 1-2 punch of control upgrade and backgage upgrade adds years to the life of your CI press brake, reducing setup times along the way.

Installation Includes

Installation of a new 5-axis backgage

A limited Planned Maintenance Service inspection on the CINCINNATI Press Brake.

Backgage demonstration.

One-year parts and labor warranty.

Specifications

The low profile backgage provides independent control of two front-to-back (X1, X2) axes, two left-to-right (Z1, Z2) axes and one up-down (R) axis.

Horizontal

Front-to-back range: 0 - 24”

Three alternate gage points, 40” max

Positioning speed: 1,200 IPM

Positioning accuracy: + 0.001”

Positioning repeatability: + 0.001”

Vertical

Height Range: 8”

Low Position: 0.5”-8.5”

High Position: 3.25”-11.25”

Over the Top Position: 5”-13”

Positioning speed: 300 IPM

Positioning accuracy: + 0.005”

Positioning repeatability: + 0.003”

Lateral

Left-to-right range: Varies based on machine length

Positioning speed: 3,000 IPM

Positioning accuracy: + 0.015”

Positioning repeatability: + 0.015”

Includes:

Two gage finger bases, two-step fingers, two solid fingers

Steel rear guarding with electrically interlocked gate

Gage modes: Standard, Independent, Taper

Graphical Gage Finger Library

Flange correction dialog

Automatic Z-axis position calculation

Closed-loop servo drive systems provide fast precise locked-in gage positions

One year parts and labor warranty

Capacity

The backgage is designed to process up to 1/4" thick material that can be handled by one or two operators. The dual drive has exceptional stability under load and ensures low wear on critical drive components. Thicker materials weighing up to 150 pounds, but not requiring a crane assist, can be processed when reasonable care is exercised.