The Workhorse

You Need

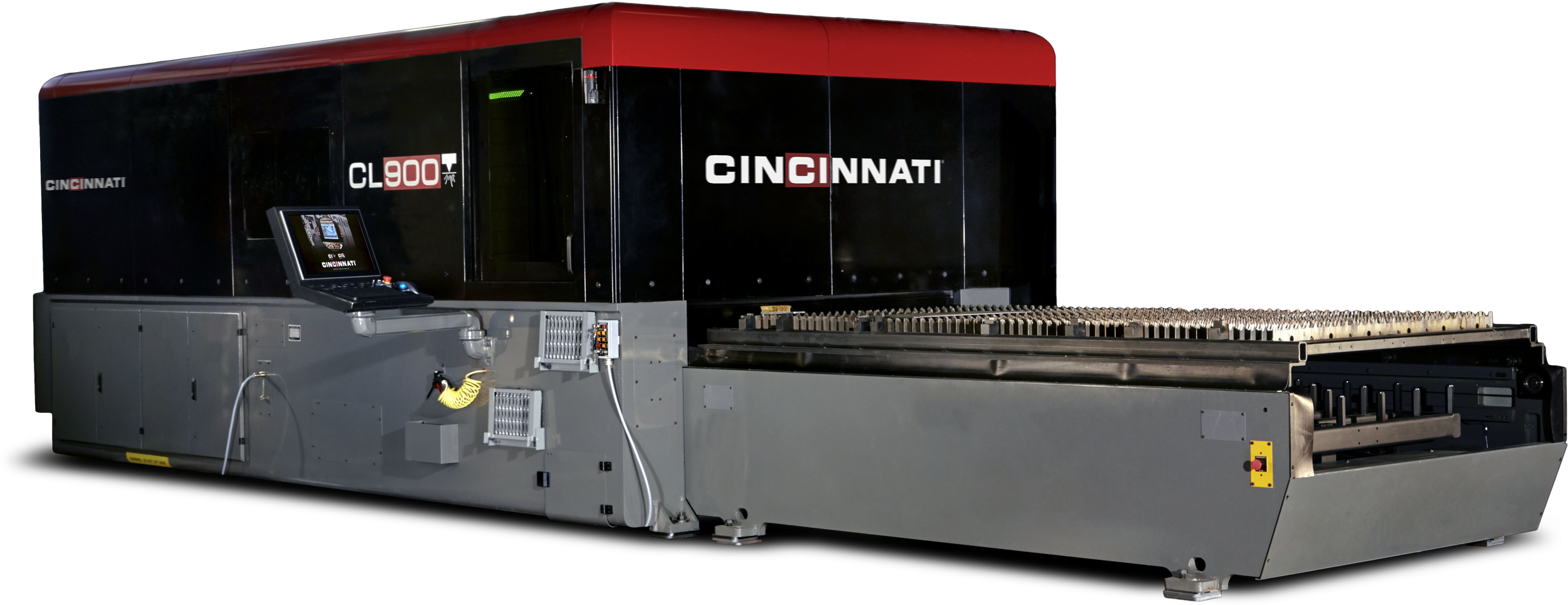

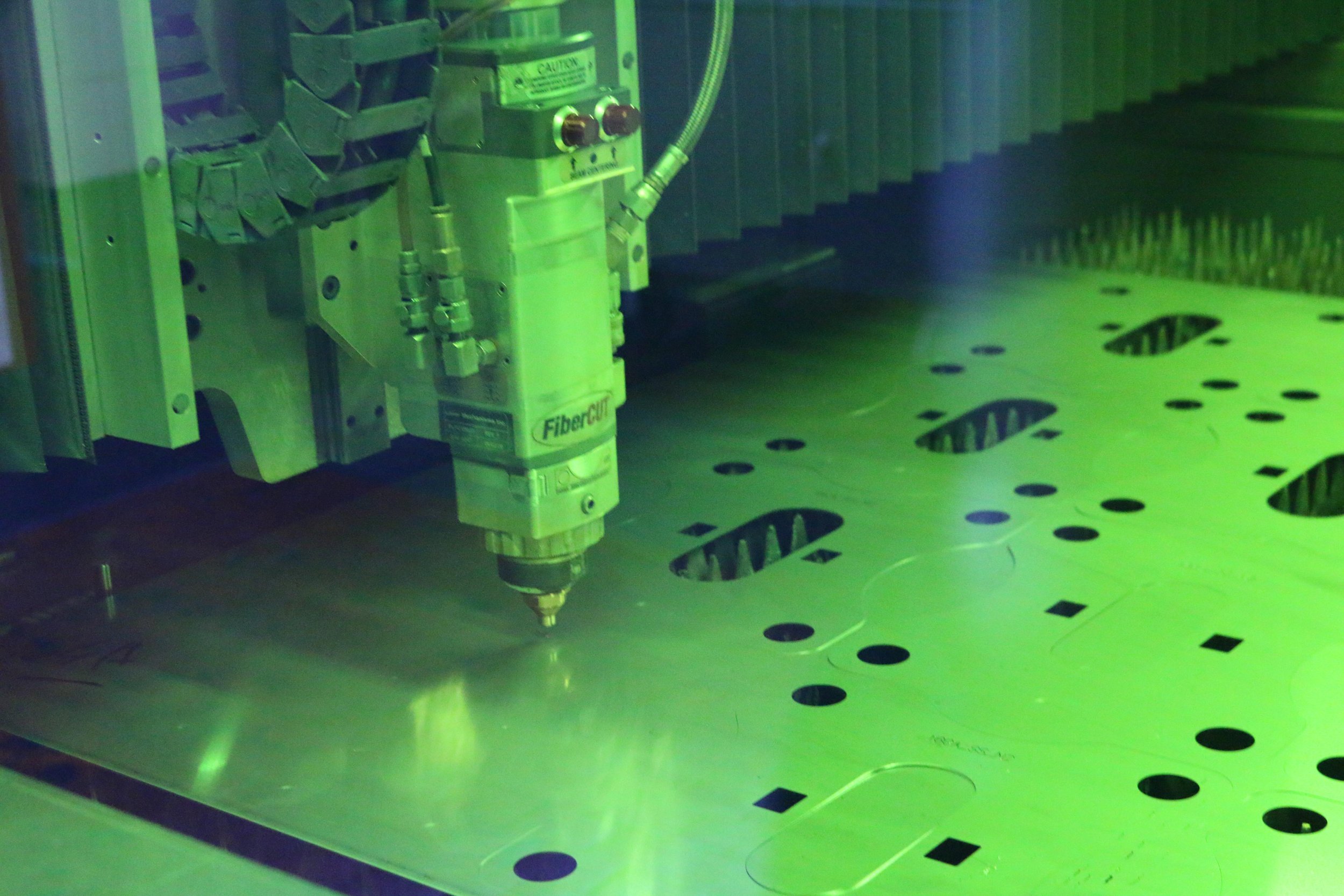

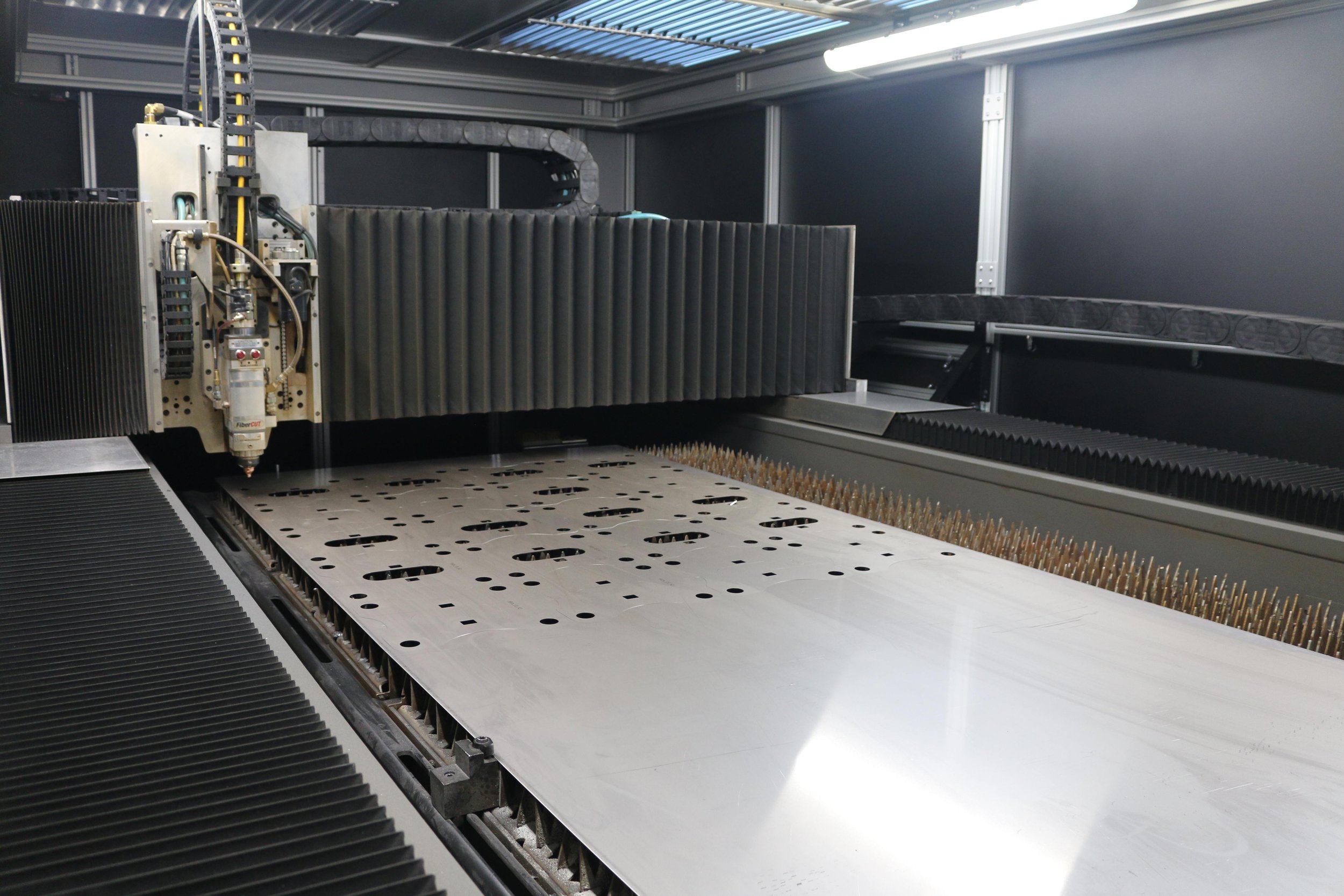

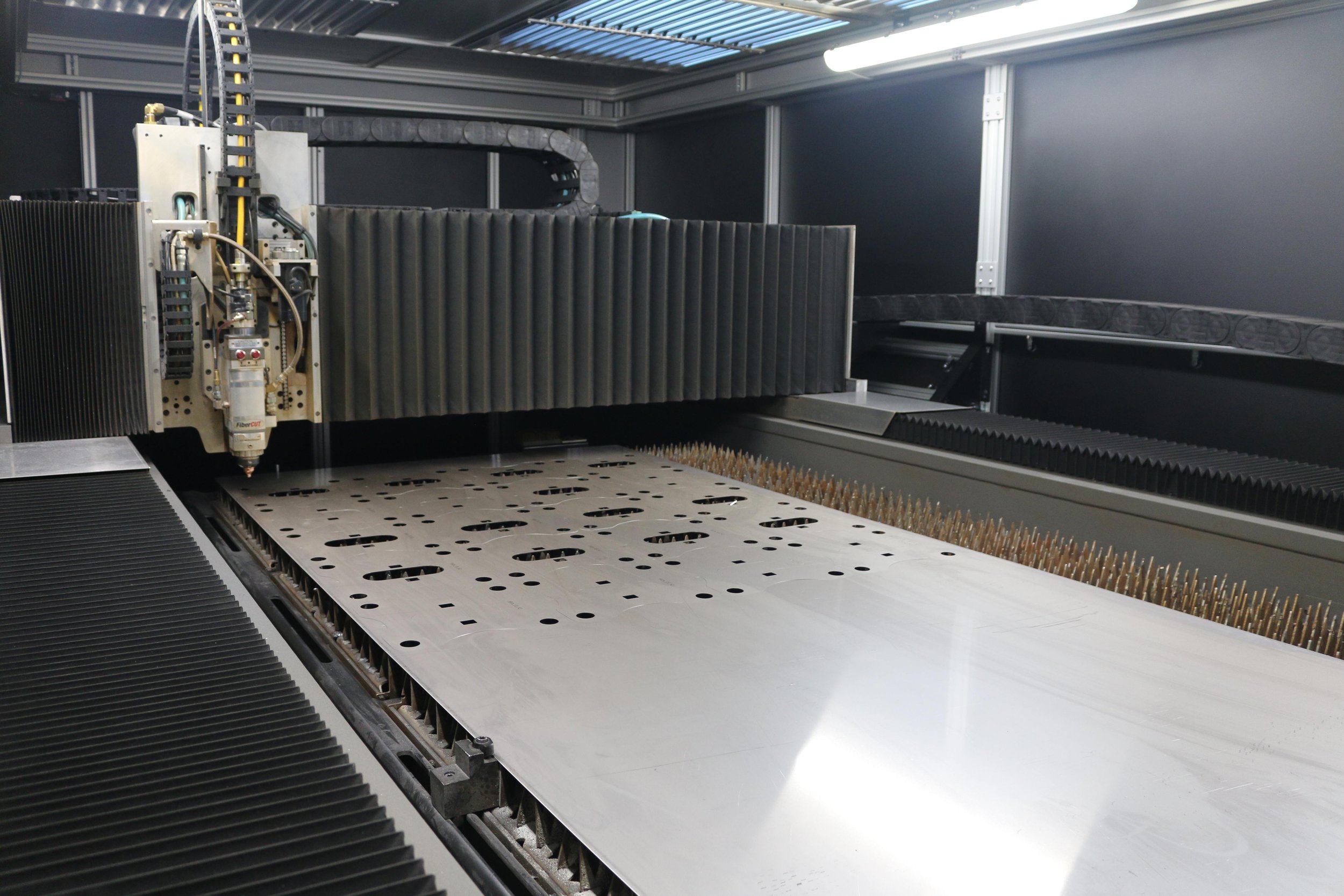

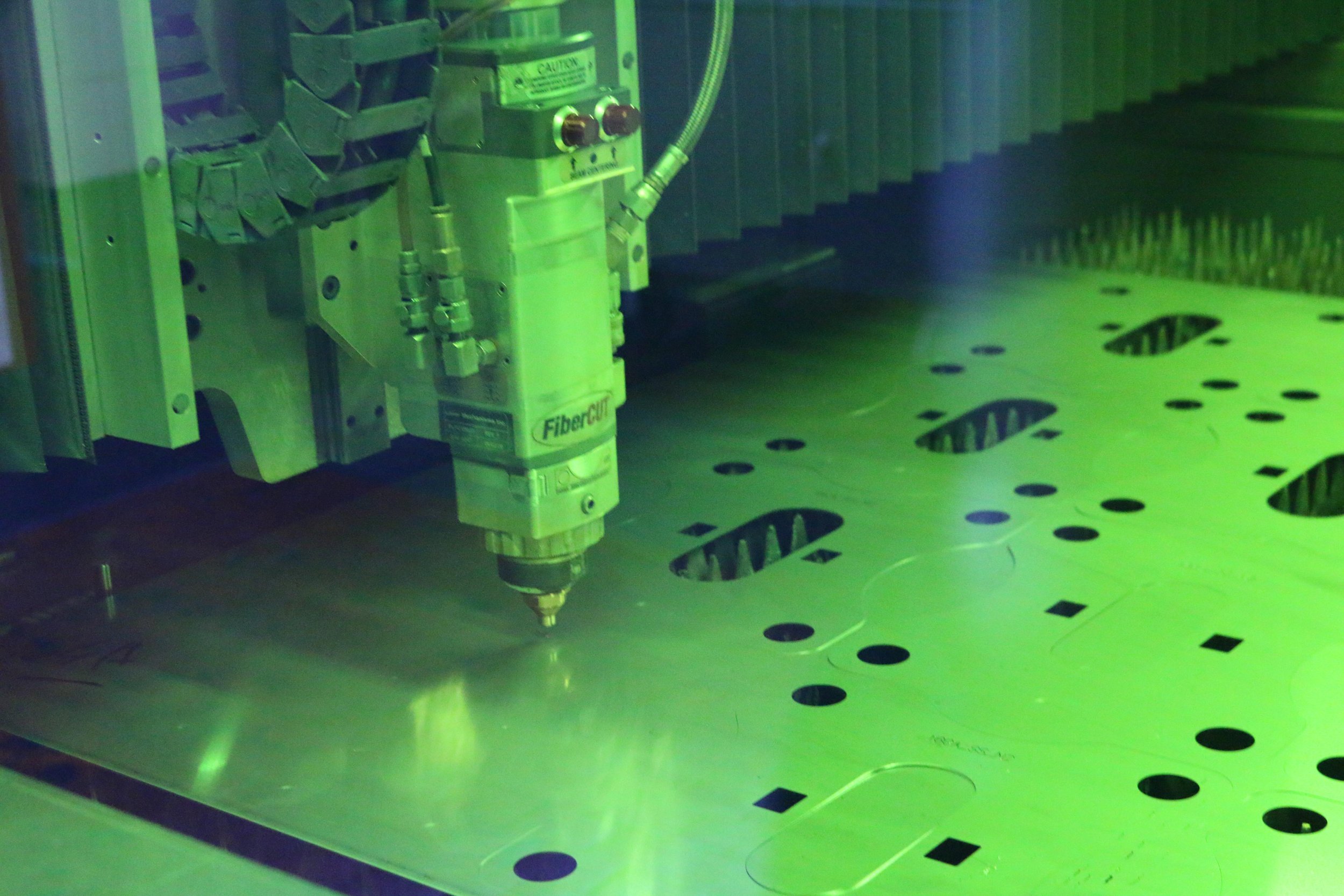

The CL-900 Fiber Laser is a powerful, precise, and reliable laser cutting system that will help you take your manufacturing facility to the next level.

Unleash Unprecedented Speed and Accuracy

With a high-resolution touchscreen control, selectable light sources, and a linear motor drive system for speed and accuracy—this laser will help you work faster than ever before. Plus, it has a dual pallet configuration that lets you load two different materials at once!

This laser is an industry workhorse with positioning accuracy @ +/- .001” over the entire cutting range!

Power for what you need

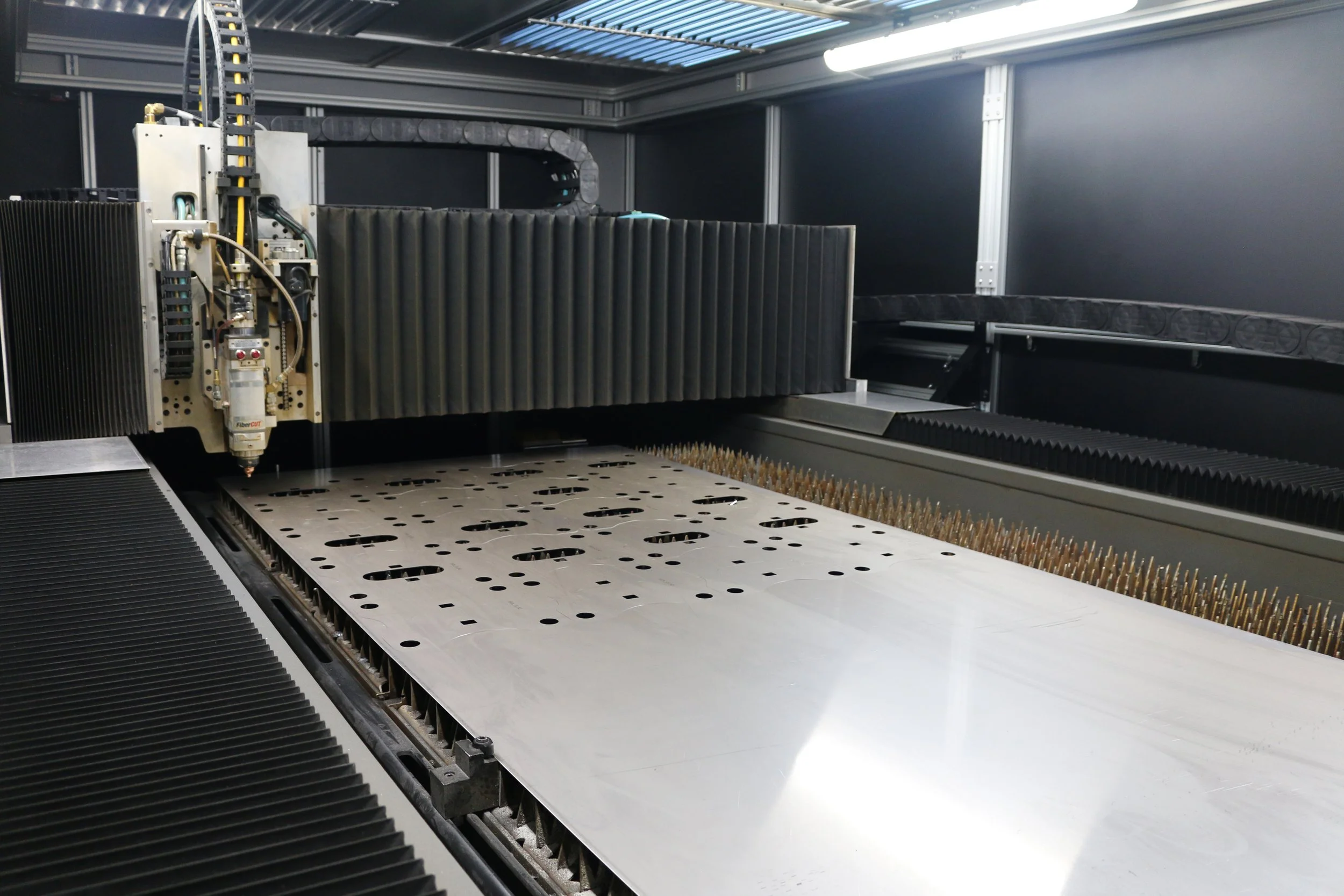

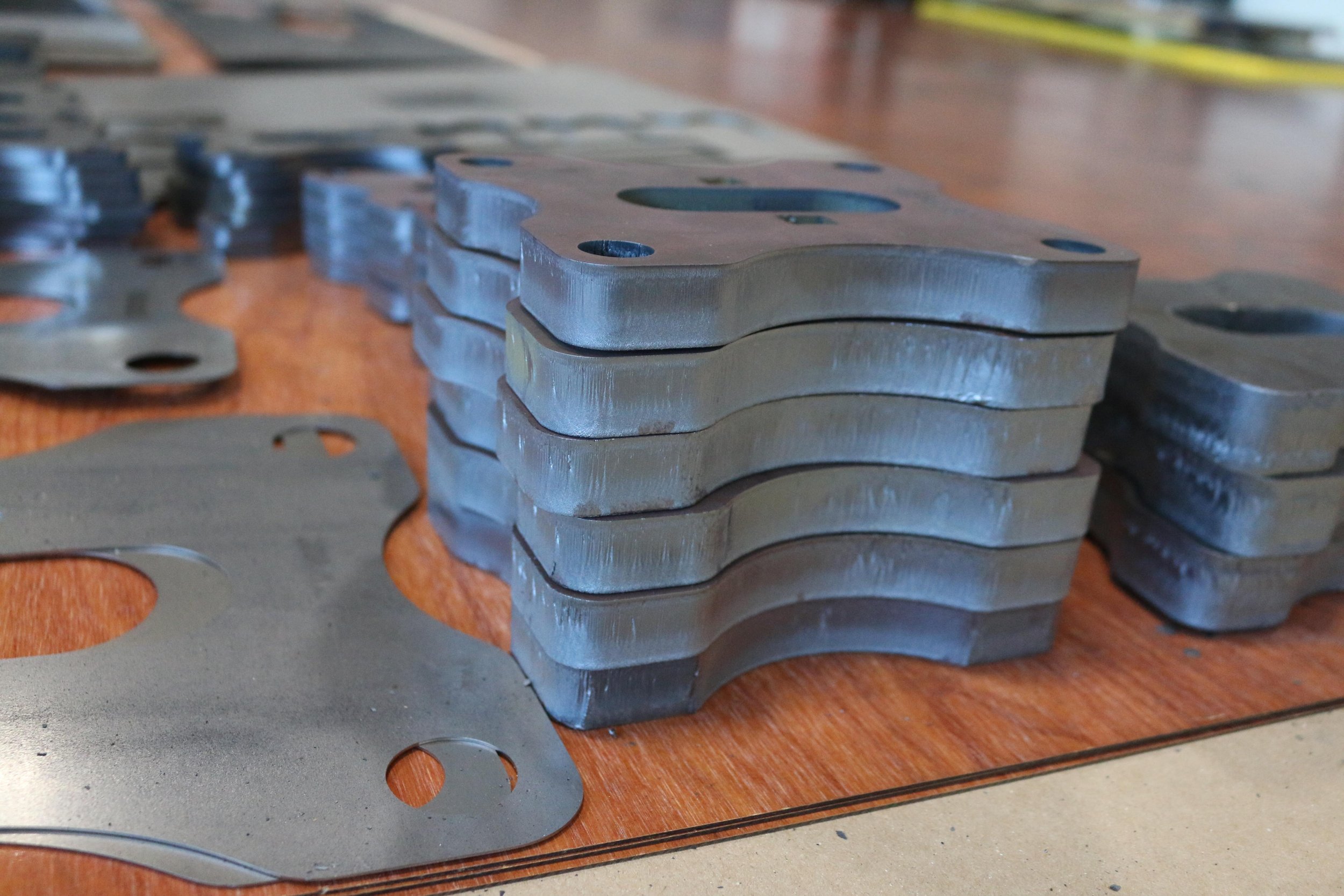

Whether you need high throughput on thin gauge material or exceptionally high edge quality on thicker materials, the CL-900 fiber laser cell delivers.

Key Features

-

Maximize Part Quality

With the CL-900’s Dynamic Power Control (DPC), automatically monitor your laser power and cutting feedrate to optimize part quality and processing time.

-

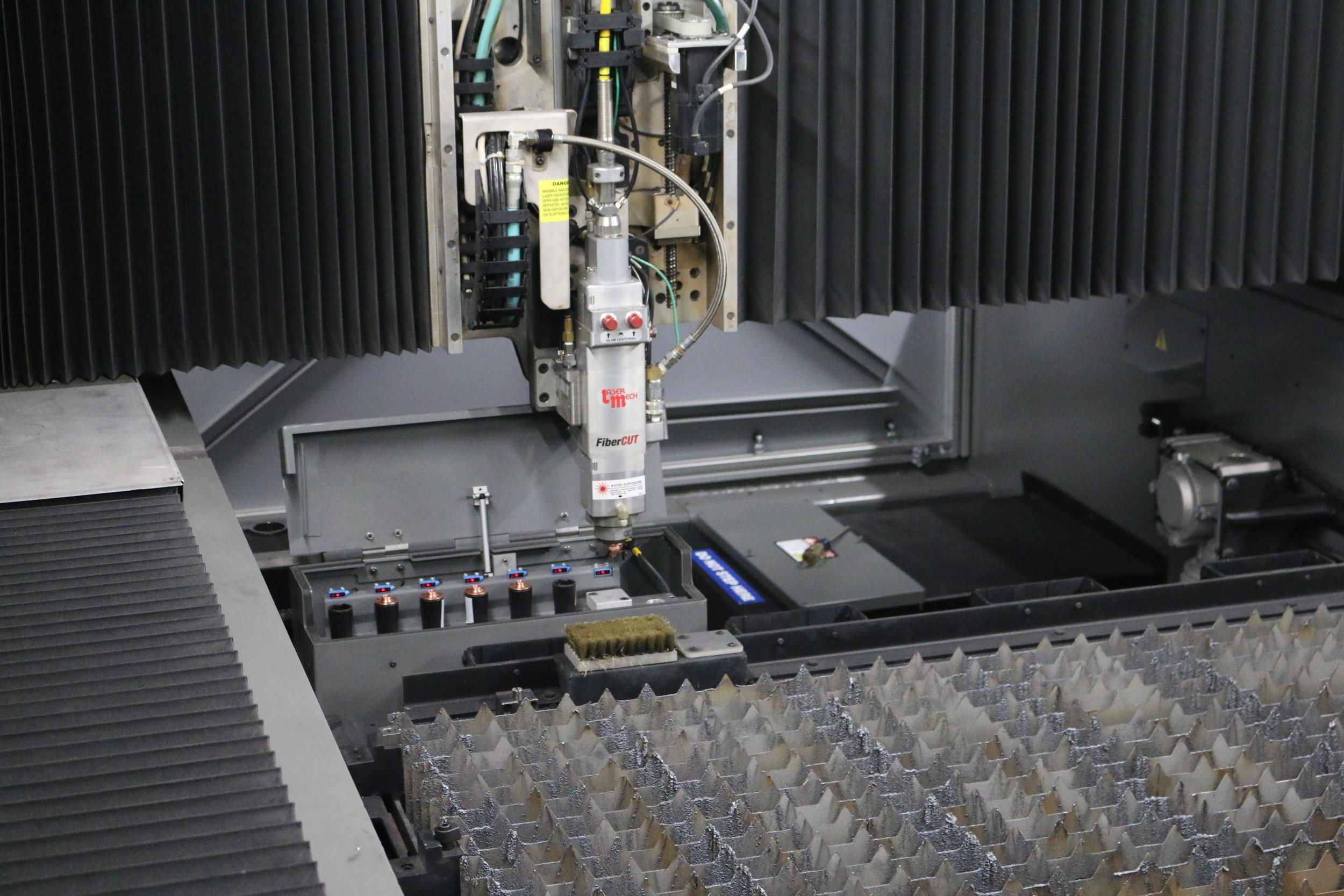

Easy-To-Use Controls

Your operators will enjoy the high resolution, 22” touchscreen control with a Windows-based operating system allowing them to watch their programs and parts being produced.

-

Accurate and Reliable Drive System

A non-mechanical drive system that does not wear and provides rapid traverse speeds of 12,020 ipm and acceleration rates in excess of 2.3 G. Positioning accuracy @ +/- .001” over the entire cutting range.

-

Consistent Beam Delivery

Fiber Optic Beam Delivery eliminates the need of a special purged environment for the beam delivery system. No mirrors mean less alignment maintenance, more consistent performance and better reliability.

-

Efficient Dual Pallet Configuration

The time between sheets is only the pallet shift time and does not include the time to unload and reload the pallet.

-

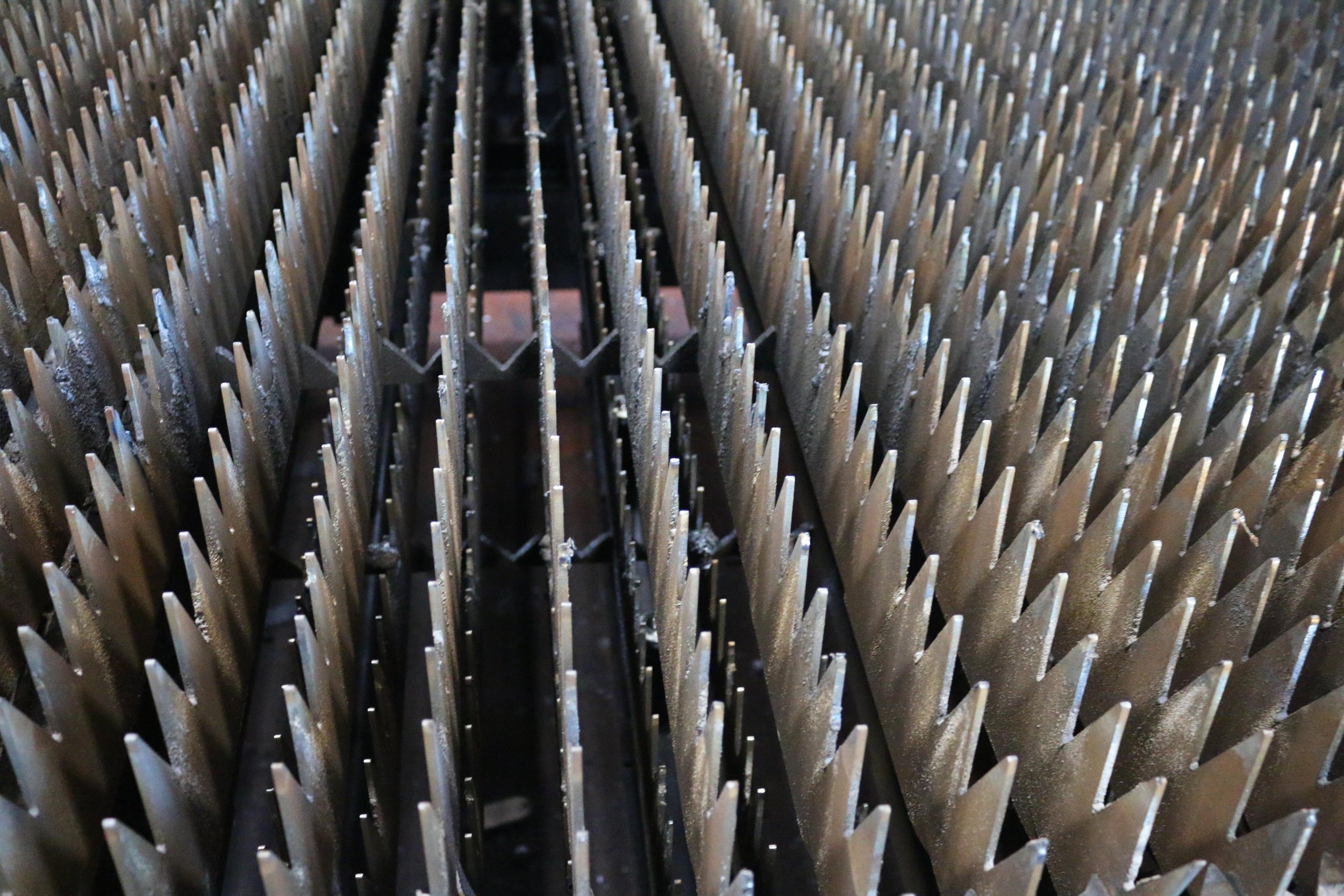

Easy Scrap Removal System

The unique design of the scrap removal system eliminates the need of using a high-maintenance, moving conveyor system.

Specifications

Available in the following table sizes: 5' x 10', 2M x 4M

Due to a continuous product development program, engineering data and dimensions are subject to change without notice. Certified foundation plans will be furnished for each installation.

| Pallet Dimensions | 60" x 120" / 5' x 10' / 1,524 mm x 3,048 mm | 2m x 4m |

|---|---|---|

| A | 124.3" (3,157 mm) | 143.2" (3,637 mm) |

| B | 189.2" (4,806 mm) | 208.2" (5,288 mm) |

| C | 96" (2,438 mm) | 96" (2,438 mm) |

| D | 261" (7,137 mm) | 323.5" (8,217 mm) |

| E | 387" (9,830 mm) | 468.2" (11,892 mm) |

| F | 39.6" (1,006 mm) | 39.6" (1,006 mm) |

| Weight | 31,950 lbs (14,492 kg) | 37,400 lbs (16,964 kg) |

Available Software

-

Nesting Pro

Amplify your ability to nest your laser parts with software automation, and create optimized machine code to make your Cincinnati laser (and most other lasers) operate at top performance

-

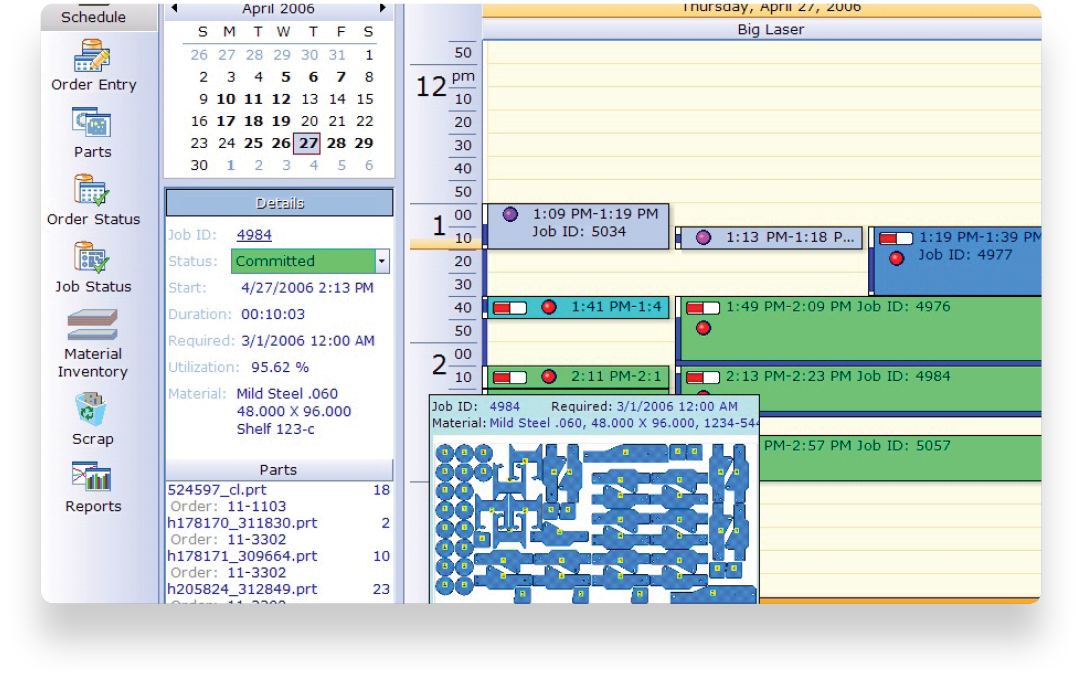

Scheduler

Take the stress out of scheduling by automatically scheduling multiple jobs across multiple shifts and multiple CI lasers.

-

CIberDash

Get real-time insight into all of your CI machines anytime from any device.

Featured Add-On

Assist Gas Cutting is a self-contained, palletized source for providing enough air assist gas for cutting parameters that require up to 275psi at a nozzle of up to 0.100" diameter. The palletized system also provides 90 psi air for the purge and nozzle cooling requirement.